Working with dangerous substances requires thorough knowledge of safety measures and regulations. This section will help guide you through the essential protocols needed to ensure proper handling and compliance in environments where these materials are present.

Becoming proficient in recognizing risks, understanding labels, and applying safety standards is crucial for maintaining a safe workplace. The process involves both theoretical knowledge and practical application to prevent accidents and protect employees and property.

Through this guide, you will explore key topics related to material safety training, common issues faced in compliance assessments, and the best practices for successfully navigating the training process. Mastering these concepts is not only essential for passing safety evaluations but also for contributing to a culture of responsibility and awareness in the workplace.

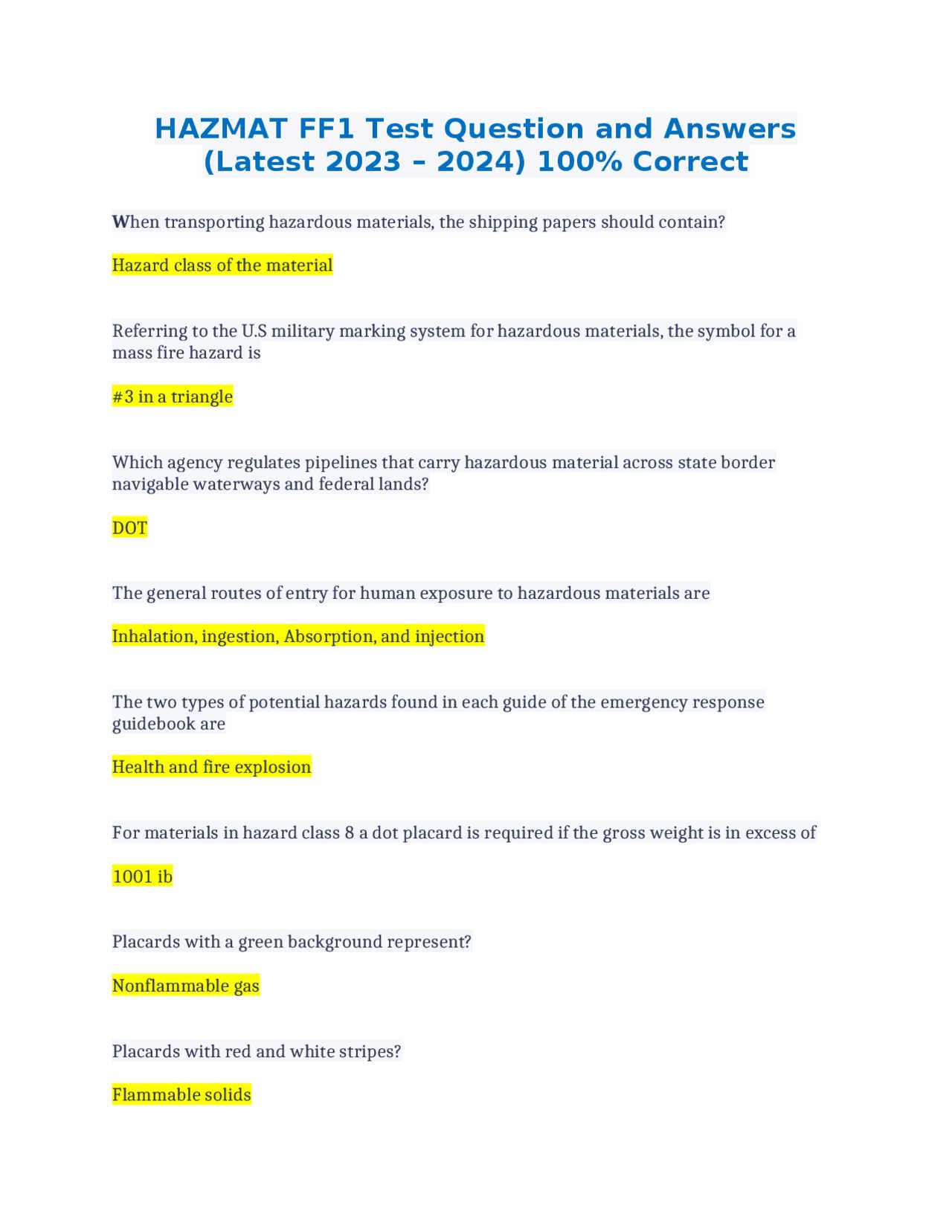

Hazardous Materials Safety Assessment for Employees

Understanding the safety measures for working with dangerous substances is vital for every worker. Employees must demonstrate their knowledge of the rules, guidelines, and procedures that ensure both their safety and the safety of others in the workplace. The training process tests their understanding and readiness to manage potential risks effectively.

This section provides insights into what is expected during the safety assessment and how to approach the preparation process. By focusing on the key areas covered in the evaluation, workers can feel confident in their ability to pass and apply this knowledge in real-world scenarios.

- Identification of Dangerous Materials: Recognizing and understanding the properties of hazardous substances.

- Safety Procedures: Knowing the correct protocols for storage, handling, and transportation.

- Labeling and Symbol Recognition: Being able to identify and interpret various warning signs and safety labels.

- Emergency Response: Understanding the steps to take in case of spills, leaks, or accidents.

- Legal Compliance: Familiarity with industry regulations and standards for managing dangerous goods.

Passing the assessment involves not only memorizing facts but also understanding how to apply the knowledge practically. It is crucial to review all training materials thoroughly and stay up-to-date with the latest safety regulations to ensure a successful evaluation.

- Study safety materials carefully to familiarize yourself with key concepts.

- Pay attention to any practical scenarios provided during training.

- Ask questions if any aspects of the procedures are unclear.

- Focus on the key areas most frequently tested in evaluations.

Preparation for the safety assessment is a step-by-step process that helps workers not only pass but also ensure their readiness for the tasks ahead. With the right focus and attention to detail, employees can confidently demonstrate their ability to manage hazardous materials safely in the workplace.

Understanding the Certification Process for Handling Hazardous Materials

Obtaining certification to work with dangerous substances is a crucial step in ensuring a safe working environment. This process involves acquiring the necessary knowledge and skills to handle these materials correctly and in compliance with safety regulations. The certification ensures that employees understand the risks and are capable of following established procedures to minimize hazards.

To achieve certification, workers must complete a training program designed to teach them about the different types of dangerous materials, safety measures, emergency protocols, and legal requirements. The certification process typically includes both theoretical instruction and practical exercises, aimed at reinforcing safe practices in real-world scenarios.

After completing the required training, candidates usually undergo an assessment to evaluate their understanding of key concepts and their ability to apply them. This assessment helps confirm that individuals are ready to work in environments where hazardous materials are handled.

Key Topics in Safety Assessment for Handling Hazardous Materials

When preparing for a safety evaluation in environments where dangerous substances are present, it’s essential to focus on the core areas that will be assessed. Understanding the critical concepts and procedures will help ensure a thorough understanding of how to manage risks and comply with safety standards. These key areas not only test knowledge but also practical application in day-to-day tasks.

- Types of Hazardous Materials: Learn about the different categories of dangerous substances, such as flammable, corrosive, and toxic materials.

- Handling and Storage Procedures: Understand the best practices for safely handling, storing, and disposing of hazardous materials.

- Safety Symbols and Labeling: Recognize the various warning signs, symbols, and labels used to identify dangerous substances and their properties.

- Emergency Response Protocols: Familiarize yourself with the procedures to follow in case of an emergency, such as spills, leaks, or accidents.

- Regulatory Compliance: Know the legal requirements for working with hazardous materials and how to ensure compliance with industry regulations.

These topics are fundamental to ensuring both personal and workplace safety when interacting with dangerous substances. By focusing on these key areas, employees can build the necessary skills to manage risks effectively and pass their assessments with confidence.

- Study the different categories of hazardous materials and their specific characteristics.

- Review the correct procedures for handling and disposing of dangerous substances.

- Learn to interpret safety labels and symbols accurately.

- Understand emergency response actions in detail.

- Ensure you are familiar with the relevant safety regulations and compliance requirements.

Mastering these subjects will provide a solid foundation for passing the safety evaluation and applying this knowledge on the job to maintain a secure working environment.

Common Mistakes in Safety Testing for Hazardous Materials

During safety assessments for working with dangerous substances, many individuals make common errors that can negatively impact their performance. These mistakes often stem from misunderstandings or lack of focus on critical safety measures. Recognizing and avoiding these pitfalls is key to passing the assessment and ensuring a safe work environment.

One of the most frequent mistakes is failing to understand the significance of proper labeling and identification of hazardous materials. Misinterpreting or overlooking labels can lead to dangerous situations, especially in emergency scenarios. Another common error is not being thoroughly familiar with safety procedures, which can lead to incorrect actions when responding to spills, leaks, or accidents.

- Ignoring Safety Labels: Failing to recognize or understand the importance of safety symbols and labels is a critical error.

- Overlooking Emergency Procedures: Inadequately preparing for emergency situations, such as spills or exposure, can lead to unsafe actions.

- Misunderstanding Storage Requirements: Not following the correct protocols for storing dangerous materials can result in accidents.

- Not Following Legal Regulations: Failing to comply with industry regulations and guidelines can cause serious safety violations.

- Lack of Attention to Detail: Rushing through the material or neglecting to review key concepts can result in gaps in knowledge.

Addressing these mistakes requires focused preparation, careful review of safety procedures, and an understanding of the critical role these factors play in ensuring a secure working environment. By recognizing common errors and actively avoiding them, individuals can improve their safety awareness and performance during assessments.

How to Prepare for the Safety Assessment

Preparing for a safety evaluation when working with dangerous substances requires a clear understanding of the necessary protocols and procedures. To ensure success, candidates should focus on learning the essential concepts, reviewing key materials, and practicing practical applications of safety measures. The preparation process is crucial for building the knowledge and confidence needed to perform well during the assessment.

The following steps can help streamline the preparation process and enhance performance:

- Review Key Safety Procedures: Make sure you are familiar with the guidelines for handling, storing, and disposing of hazardous substances.

- Study Emergency Protocols: Understand the actions to take in case of an incident, including spills, leaks, and exposure.

- Learn Regulatory Requirements: Be aware of the legal and safety regulations governing the handling of dangerous materials.

- Familiarize Yourself with Safety Symbols: Know how to identify and interpret various safety labels and warning signs.

- Practice with Real-Life Scenarios: Use case studies or practice tests to apply knowledge in simulated situations.

In addition to these steps, it’s important to stay organized and ensure consistent review of all relevant materials. Regularly revisiting the training content and seeking clarification on any unclear points will significantly improve your preparedness.

By following these preparation strategies, individuals can ensure they are well-equipped to handle the safety assessment with confidence and accuracy, ultimately leading to a successful certification process.

Amazon’s Safety Standards for Handling Dangerous Materials Explained

Ensuring a safe environment when working with hazardous substances is a top priority in many industries. Specific safety standards are put in place to protect employees, customers, and the environment from the risks associated with these materials. In this section, we’ll explain the core safety protocols adopted to guarantee safe handling, storage, and transportation of dangerous goods in workplace settings.

Key Safety Principles

Amazon’s safety standards emphasize the identification and classification of dangerous substances. The primary goal is to reduce the risk of accidents by ensuring that every employee understands the different types of hazardous materials and the appropriate safety measures to take. These principles guide workers in safely handling materials from the moment they are received until they are properly disposed of or delivered to their final destination.

Regulatory Compliance and Procedures

In addition to internal safety protocols, employees must adhere to both national and international regulations regarding the handling of dangerous materials. Amazon’s safety guidelines ensure that workers follow procedures that align with legal requirements, reducing the likelihood of unsafe practices. Compliance with these regulations is regularly checked through audits and training sessions, helping to maintain high standards of safety across the organization.

By understanding and following these standards, employees can contribute to a safer work environment and ensure the efficient handling of hazardous substances in line with both company policy and regulatory demands.

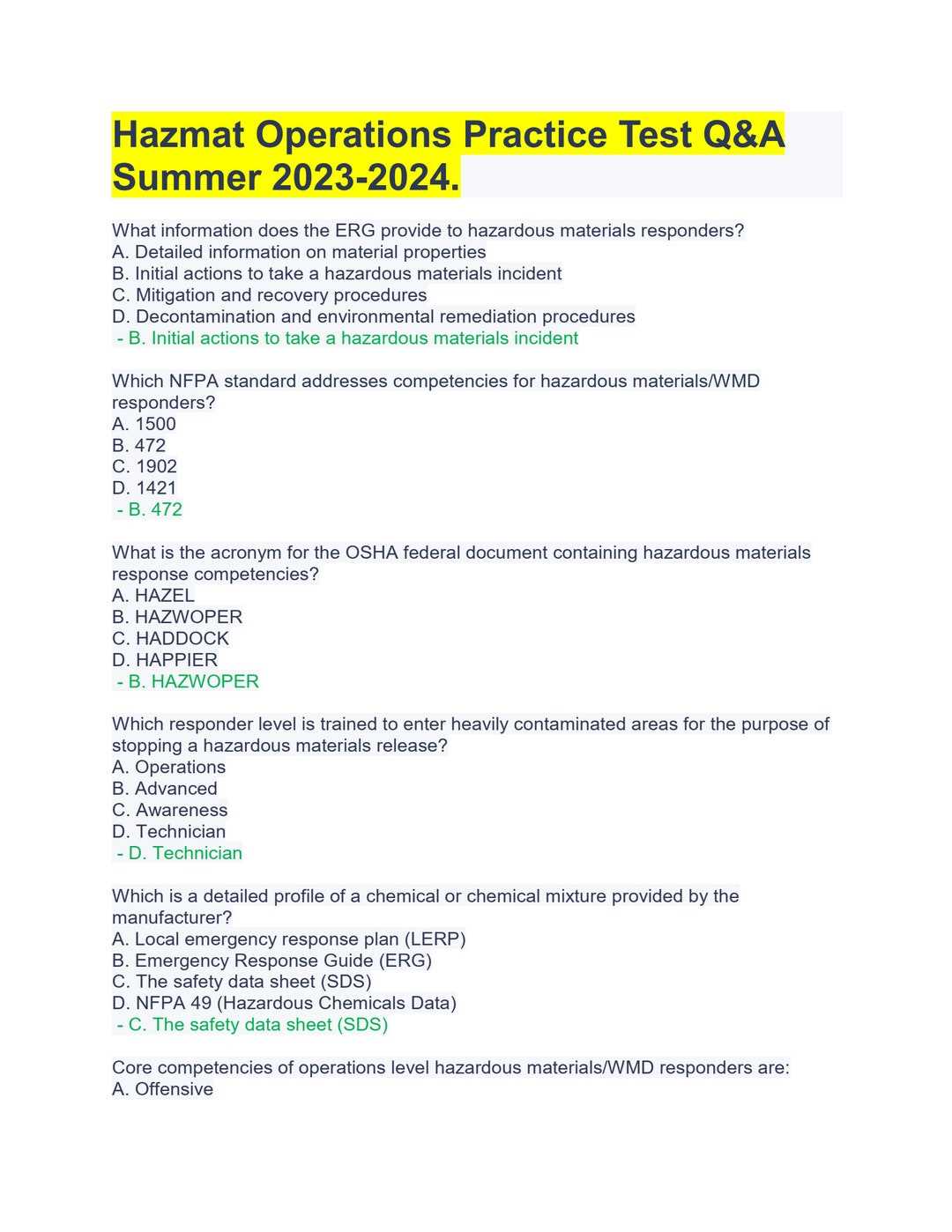

What to Expect in the Safety Test for Handling Hazardous Materials

The safety test for working with hazardous substances is designed to evaluate your understanding of key procedures and protocols. It tests your knowledge of safe practices, regulatory compliance, and emergency response measures. The assessment typically covers both theoretical concepts and practical applications, ensuring that individuals are well-prepared for real-world situations where dangerous materials are involved.

During the assessment, candidates can expect a variety of question types, ranging from multiple-choice questions to scenario-based problems. The focus will be on your ability to recall essential safety information and make quick, accurate decisions in emergency situations. Here’s a breakdown of the topics you are likely to encounter:

| Topic | What You’ll Learn |

|---|---|

| Identification of Hazardous Materials | Recognizing and understanding the properties of dangerous substances. |

| Safety Procedures | Learning proper handling, storage, and disposal techniques to prevent accidents. |

| Emergency Response Actions | Understanding how to react to spills, leaks, or exposure to harmful materials. |

| Labeling and Symbols | Interpreting safety labels and symbols for hazardous substances. |

| Regulatory Compliance | Understanding legal requirements and industry standards for handling hazardous materials. |

It’s important to review the key concepts in these areas before the assessment. Being well-prepared will not only help you perform well but also ensure that you are ready to safely handle hazardous materials in the workplace.

How Long Does the Safety Assessment Take

The length of the safety assessment for handling hazardous materials can vary depending on the specific requirements of the company or certification program. On average, the assessment typically lasts between one to two hours. However, the exact duration can depend on factors such as the complexity of the material being covered and the format of the test itself.

The assessment is designed to test both theoretical knowledge and practical understanding, so you may encounter a combination of multiple-choice questions, scenario-based evaluations, and practical exercises. Depending on the testing method, some individuals may take longer to complete the entire process, while others may finish more quickly.

It is important to pace yourself during the assessment and ensure that you carefully read and understand each question. Rushing through the test can lead to mistakes, while taking your time to think through the answers will improve your chances of success.

Tips for Passing the Safety Assessment for Handling Hazardous Materials

Successfully completing the safety assessment for working with dangerous substances requires a combination of preparation, focus, and a clear understanding of the key concepts. Whether you are taking this test for the first time or refreshing your knowledge, following a few strategic tips can improve your chances of passing and ensure you are well-prepared for the challenges ahead.

Review Safety Protocols Thoroughly: Familiarize yourself with all the safety guidelines and procedures related to the handling, storage, and disposal of hazardous substances. A deep understanding of these protocols will help you answer most of the questions accurately.

Practice Scenario-Based Questions: Many assessments include practical scenarios to test how you would respond in real-life situations. Practicing these types of questions can give you a better sense of what to expect and help you think critically when presented with similar problems during the test.

Stay Calm and Focused: It’s important to stay calm during the assessment. Rushing through the questions or panicking can lead to mistakes. Take your time, read each question carefully, and ensure you fully understand it before selecting your answer.

Study the Labels and Symbols: Many questions will focus on your ability to recognize and understand various safety labels and symbols. Make sure you are comfortable with the different warning signs and the information they convey.

Understand the Legal and Regulatory Framework: Being familiar with the legal requirements for handling hazardous materials is crucial. The test may cover regulations that govern safe practices in your industry, so ensure you are well-versed in these laws.

By following these tips and preparing ahead of time, you’ll be more confident and ready to pass the assessment with success. Focused study, practice, and attention to detail will set you up for a strong performance.

Understanding Safety Symbols and Labels

In industries where dangerous materials are present, proper identification and communication are crucial to maintaining safety. One of the key ways to ensure that hazardous substances are handled correctly is through the use of symbols and labels. These visual indicators convey vital information about the risks associated with certain materials, helping workers take the necessary precautions to avoid accidents. Understanding these symbols and labels is essential for anyone working with or around these substances.

Labels and symbols are often designed to be easily recognizable and provide quick guidance in emergency situations. These markings are used on containers, packaging, and transport vehicles to alert individuals to the specific hazards present, from toxicity to flammability. Knowing how to interpret these labels will help you respond appropriately to any situation involving hazardous materials.

| Symbol | Meaning |

|---|---|

| ☠️ | Toxic or Fatal if Inhaled, Swallowed, or Absorbed |

| Flammable or Combustible | |

| ⚠️ | General Hazard, May Cause Irritation |

| ☢️ | Radioactive Materials |

| Corrosive Materials (Can Damage Living Tissue) |

Each symbol represents a specific risk, and being familiar with these markings can significantly reduce the chances of an accident. It is important to not only recognize the symbols but also understand their meaning and how to react in case of exposure to these materials. Ensuring that these symbols are visible and clearly understood is part of maintaining a safe working environment.

Company’s Hazardous Materials Training Program

Effective training for handling dangerous substances is crucial in ensuring the safety of workers and the environment. Companies that deal with these materials often provide specialized programs aimed at educating employees on the proper handling, storage, and disposal techniques. These training initiatives are designed to prepare staff to recognize potential risks, follow safety protocols, and act swiftly in emergency situations.

One such program focuses on equipping individuals with the knowledge they need to manage hazardous materials safely. It covers a range of topics from identifying chemical hazards to understanding the proper labeling and documentation required when working with potentially dangerous substances. This comprehensive training ensures that employees are not only aware of the risks but also know how to mitigate them effectively.

Key Components of the Training Program:

- Understanding Material Safety Data Sheets (MSDS): Employees are taught how to read and interpret these important documents that outline the properties of hazardous substances.

- Safe Handling Techniques: Proper methods for safely transporting, storing, and disposing of chemicals are covered in detail.

- Emergency Response Procedures: The program emphasizes the importance of knowing how to react in case of spills, leaks, or other emergencies involving hazardous materials.

- Regulatory Compliance: Employees are educated on relevant laws and regulations that govern the use of hazardous materials, ensuring they remain compliant with industry standards.

By participating in this training program, employees gain the essential skills needed to reduce the risk of accidents and maintain a safe working environment. These sessions are an integral part of the company’s commitment to health, safety, and environmental responsibility.

Common Hazardous Materials in the Workplace

In industries that deal with chemicals, certain substances are regularly handled and require special precautions due to their potential risks. These materials can range from flammable liquids to corrosive chemicals, and they all require specific safety measures during handling, transportation, and storage. Recognizing these materials and understanding their properties is crucial for maintaining a safe working environment.

There are several types of dangerous substances commonly encountered in various industries. Some are used in manufacturing processes, while others may be part of the packaging or shipping procedures. Regardless of their use, each of these materials requires careful attention to safety standards and regulatory guidelines. Below are some examples of materials that are often present in workplaces:

- Flammable Liquids: These include solvents, oils, and other liquids that ignite easily. Special storage and handling practices are necessary to prevent fire hazards.

- Corrosive Substances: Chemicals like acids and alkalis that can cause severe damage to living tissue and materials. Proper protective equipment and containment are essential when working with these substances.

- Toxic Compounds: These materials, when inhaled, ingested, or absorbed, can cause harm to human health. These often include pesticides, certain solvents, and industrial chemicals.

- Reactive Materials: Substances that can undergo dangerous chemical reactions under specific conditions, such as heat or contact with other chemicals. Proper labeling and secure storage are vital to prevent accidents.

- Compressed Gases: Gases stored under high pressure, such as oxygen, propane, and nitrogen, which can pose explosion risks if mishandled.

Ensuring that employees are aware of these materials and know the correct procedures to follow when interacting with them is key to preventing accidents and maintaining workplace safety. Proper training, use of personal protective equipment, and adherence to safety guidelines all contribute to minimizing the risks associated with these hazardous substances.

How to Navigate Hazardous Materials Test Questions

When preparing for a test focused on handling dangerous substances, it is essential to approach each question with a clear understanding of the safety protocols and best practices involved. The key to success lies in being able to interpret the question correctly, applying your knowledge of safety regulations, and recognizing potential hazards in various scenarios. Below are strategies for effectively navigating through questions related to the safe handling, storage, and disposal of hazardous substances.

1. Read Each Question Carefully:

It’s easy to make mistakes if you rush through the questions. Take the time to read each one thoroughly to understand what is being asked. Look for key phrases such as “best practices,” “emergency response,” or “safety precautions,” which can help guide your answer choices.

2. Identify Common Safety Standards:

Many test questions revolve around the correct handling of hazardous materials. It’s helpful to memorize the most common safety standards, such as proper labeling, storage requirements, and emergency protocols. Understanding these basics can help you quickly eliminate incorrect answers.

3. Understand Key Regulations and Guidelines:

- Labeling Requirements: Ensure that you are familiar with how hazardous substances should be labeled, including symbols, warning signs, and handling instructions.

- Proper Storage Procedures: Know how different types of materials should be stored to avoid chemical reactions, leaks, or fires.

- Personal Protective Equipment (PPE): Familiarize yourself with the types of PPE required for different hazardous materials, such as gloves, masks, or eye protection.

4. Think About Risk Factors:

Test questions may ask you to assess the risks associated with certain situations or materials. Remember that hazardous substances often pose multiple dangers, including toxicity, flammability, and environmental harm. Consider the material’s properties and how they influence safety measures when answering these types of questions.

5. Eliminate Unlikely Answers:

If you’re uncertain about a question, try eliminating the most obvious incorrect answers. Focus on the remaining options that seem to best align with standard safety practices or established guidelines.

By staying calm and systematically applying your knowledge of safety protocols, you can confidently navigate through the test questions and increase your chances of success. Understanding the content and anticipating common question formats will allow you to perform at your best when it matters most.

Importance of Compliance with Hazardous Materials Regulations

Ensuring proper management of hazardous substances is crucial for any company that deals with these materials. This process involves adhering to specific safety protocols designed to protect employees, the environment, and the general public. The responsibility to meet regulatory standards cannot be overstated, as failing to comply can lead to severe legal, financial, and health consequences. Understanding the importance of compliance with hazardous material regulations is essential to maintain safety, minimize risks, and avoid unnecessary incidents in the workplace.

Reducing Workplace Hazards

Compliance with safety regulations directly reduces the likelihood of accidents involving dangerous substances. Proper handling, storage, and disposal methods ensure that hazardous materials do not pose a threat to the health and safety of employees or the surrounding environment. By following safety standards, businesses can mitigate risks such as chemical spills, leaks, or explosions that could otherwise lead to serious injuries or fatalities.

Ensuring Legal and Regulatory Adherence

Each country or region has specific regulations governing the use and management of hazardous substances. For companies dealing with such materials, staying compliant with these laws is not just a safety measure but a legal obligation. Non-compliance can result in hefty fines, penalties, and even business shutdowns. Following established guidelines ensures that organizations remain within the legal framework, protecting them from costly lawsuits or regulatory actions.

Furthermore, compliance also helps to maintain a company’s reputation, demonstrating a commitment to both employee welfare and environmental stewardship. In the long run, adherence to regulations helps businesses operate efficiently while safeguarding against potential hazards, making it an integral part of corporate responsibility.

Reviewing Company’s Hazardous Materials Policies

For any organization that handles dangerous substances, having a clear set of policies and procedures is vital to ensure safety and compliance with legal standards. A comprehensive review of the company’s safety guidelines for managing hazardous materials provides clarity on how these materials should be handled, stored, transported, and disposed of. These policies are designed to protect both employees and the environment from the potential risks associated with mishandling dangerous goods.

Key Components of Hazardous Materials Policies

One of the fundamental aspects of these policies is the proper classification and labeling of substances. Understanding the different categories of dangerous materials and knowing how to identify them is crucial for preventing accidents. The policies also include detailed guidelines for handling materials safely, such as using protective equipment and ensuring that appropriate safety measures are in place to deal with emergencies like spills or leaks.

Training and Compliance Monitoring

Another essential part of these policies is employee training. Employees must be properly trained on the specific procedures for handling hazardous materials to reduce the likelihood of accidents. Regular monitoring and audits ensure that these policies are being followed and help to identify areas for improvement. Adherence to safety regulations not only helps to minimize risk but also ensures that the company remains in compliance with government regulations, avoiding potential legal and financial consequences.

By regularly reviewing and updating these safety guidelines, organizations can foster a culture of safety, making it easier for employees to follow protocols and ensuring that hazardous materials are managed responsibly throughout the workplace.

How the Company Handles Hazardous Material Shipping

Shipping dangerous substances requires careful planning and strict adherence to safety standards to prevent accidents during transport. For any organization involved in the shipment of these materials, it is critical to follow established procedures and comply with legal regulations. From packaging and labeling to transport and delivery, every step must be handled with caution to ensure that these goods do not pose a risk to employees, customers, or the environment.

Safety Protocols for Packaging and Labeling

The first step in shipping hazardous materials is ensuring that they are properly packaged and labeled. Packaging must be secure enough to prevent leaks or spills, and the labels should clearly indicate the contents, potential hazards, and handling instructions. These labels not only help inform workers during transportation but also provide essential information in case of an emergency. The company follows all required guidelines to ensure materials are classified correctly and meet safety standards.

Compliance with Shipping Regulations

To ensure safe transport, companies must comply with a variety of shipping regulations, including those set by governmental bodies and international transport organizations. These regulations include restrictions on the type of carrier, the route taken, and the methods used to handle materials in transit. In addition, every shipment of hazardous materials is carefully documented, ensuring that all information is available for inspection and that necessary precautions are taken throughout the journey.

By following strict guidelines for packaging, labeling, and shipping, the company ensures that hazardous materials are transported safely and in compliance with regulations, minimizing risks for everyone involved.

Post-Exam Steps and Certification

After completing the assessment process for handling dangerous materials, there are several important steps that follow to ensure full compliance and qualification. The journey does not end with passing the test, as further actions are required to solidify knowledge and confirm expertise. These steps are essential to guarantee that individuals are fully prepared to handle hazardous substances safely and according to industry standards.

Once the assessment is finished, candidates typically need to undergo a review of their performance. This allows for any potential gaps in knowledge to be identified and addressed. Following the review, successful candidates are usually granted a certification, which signifies their competency in managing hazardous materials. The certification not only serves as proof of knowledge but also acts as a key requirement for certain job roles in the field.

Additionally, ongoing education and periodic recertification are often necessary to maintain the certification. This ensures that individuals stay current with the latest regulations, safety protocols, and best practices for handling dangerous materials. Regular updates and training sessions help reinforce critical skills and keep the workforce prepared for any situation that may arise.

Resources for Exam Success

To excel in the assessment for handling hazardous materials, candidates can benefit from a variety of resources that enhance understanding and preparation. Access to the right materials and tools is key in mastering the subject matter and ensuring success. These resources provide both theoretical knowledge and practical application, helping candidates feel confident and ready for the challenges they may face.

One of the most valuable resources is training courses specifically designed to cover all relevant safety guidelines and regulations. These courses are often available online or in-person and can be tailored to the individual’s learning style. Interactive modules and real-world scenarios allow learners to apply their knowledge in practical contexts.

In addition to formal courses, study guides and practice tests are extremely useful in reinforcing learning. These materials typically include sample questions and detailed explanations that help familiarize candidates with the type of content they will encounter during the actual assessment. Many practice exams simulate the format and difficulty level of the real test, providing a realistic preview of what to expect.

Moreover, regulatory documents such as safety protocols, material handling procedures, and industry standards should be reviewed regularly. Keeping up-to-date with the latest safety measures and legal requirements ensures that candidates are prepared for any scenario that may arise in the workplace.

For those seeking additional support, peer groups or mentorship can be beneficial. Engaging with others who have successfully navigated the assessment process provides practical insights and shared experiences, offering guidance and encouragement throughout the preparation process.