Understanding the core functions of electrical measurement devices is essential for anyone in the field of electronics or electrical maintenance. These tools are pivotal in diagnosing and solving various circuit-related issues. The ability to use them accurately can make all the difference in determining the health of an electrical system.

The following guide will explore key concepts and methods related to these devices, focusing on their practical applications. Whether you’re a beginner or someone looking to refresh your knowledge, this resource will provide useful insights into how to interpret readings, perform tests, and troubleshoot effectively.

To ensure you are well-prepared, we will also discuss common areas covered in assessments related to these tools, offering tips to sharpen your skills. With the right approach, anyone can master the necessary techniques and use them confidently in real-world scenarios.

Understanding Measurement Tool Fundamentals

Accurate electrical testing requires a solid understanding of the key functions of measurement devices. These tools allow users to check a range of parameters, from voltage and current to resistance, ensuring the proper operation of electronic circuits and systems. Mastering their basic features and reading techniques is essential for troubleshooting and effective diagnostics in various electrical environments.

These instruments are designed to provide precise readings for different electrical properties. Knowing how to switch between modes, interpret displays, and apply the right testing methods to specific components is crucial. Proper usage can help identify faults, prevent errors, and optimize system performance in both simple and complex setups.

By familiarizing yourself with the essential functions of these tools, you can ensure you’re prepared for practical applications and assessments. Confidence in handling the device, combined with a clear understanding of measurement principles, will lead to more efficient problem-solving and a deeper grasp of electrical systems.

What to Expect in the Assessment

When preparing for an evaluation of your knowledge and skills in using electrical testing tools, it’s important to understand what key concepts and tasks will be covered. The assessment will likely focus on a combination of theoretical knowledge and practical application. Expect to be tested on various techniques, as well as your ability to accurately interpret readings and perform measurements in different scenarios.

Here are some areas that may be included in the evaluation:

- Understanding different measurement modes and their applications

- Interpreting results accurately and troubleshooting common issues

- Correctly applying safety protocols during testing

- Identifying and resolving issues in electrical circuits using measurement devices

- Calibrating the tool and understanding error margins

The questions may be a mix of multiple-choice, short-answer, and hands-on tasks where you will need to demonstrate your proficiency. It’s essential to practice using the tool in a variety of situations to gain confidence in your abilities. Pay special attention to understanding how to handle readings in different contexts and how to perform routine maintenance to keep the tool functioning accurately.

Key Concepts for the Measurement Tool Assessment

In order to successfully navigate an assessment focused on electrical measurement devices, it’s essential to grasp several key principles and techniques. Mastering these concepts ensures not only the ability to operate the device correctly but also to interpret results accurately and apply them in practical scenarios. These foundational ideas form the backbone of any evaluation related to testing instruments.

Essential Measurement Techniques

Understanding the following concepts will help you perform well in the assessment:

- Measuring voltage, current, and resistance accurately

- Switching between modes depending on the type of test

- Understanding ranges and how to adjust them for different measurements

- Reading and interpreting results from the display screen

Common Testing Scenarios

The assessment may include questions based on practical applications. Be prepared to demonstrate your ability to perform measurements in real-world situations:

- Testing a live circuit for voltage

- Measuring the current flow in a device

- Checking the resistance of a component to identify faults

- Understanding how to use continuity tests to find broken circuits

By becoming familiar with these key concepts, you will be able to confidently approach the assessment and showcase your proficiency in using the tool effectively across a range of practical situations.

Commonly Tested Measurement Functions

When preparing for an assessment of electrical testing tools, it’s essential to be familiar with the functions most commonly tested. These devices are equipped with various capabilities designed to measure electrical properties, and understanding how to use each one effectively is key to success. Knowing what to expect in terms of practical tasks and theoretical questions will help you feel confident in using these tools during the evaluation.

Here are some of the primary functions you should be comfortable with:

- Voltage Measurement: Understanding how to measure both alternating and direct current voltages is crucial. This is often the first and most common task in any test scenario.

- Current Measurement: Knowing how to measure the flow of electrical current through a circuit is essential for diagnosing issues and ensuring system functionality.

- Resistance Measurement: Accurately measuring resistance helps identify faulty components and verify the integrity of circuits and wires.

- Continuity Testing: This function is used to check if there is an unbroken path for current to flow, making it a common task for identifying open circuits.

- Diode Testing: Essential for testing the functionality of diodes within circuits, ensuring they are operating properly.

Familiarity with these basic functions, as well as the ability to switch between modes depending on the situation, will help you approach the assessment with ease. Proper use of each measurement type is fundamental to both troubleshooting and ensuring accurate results in any electrical system.

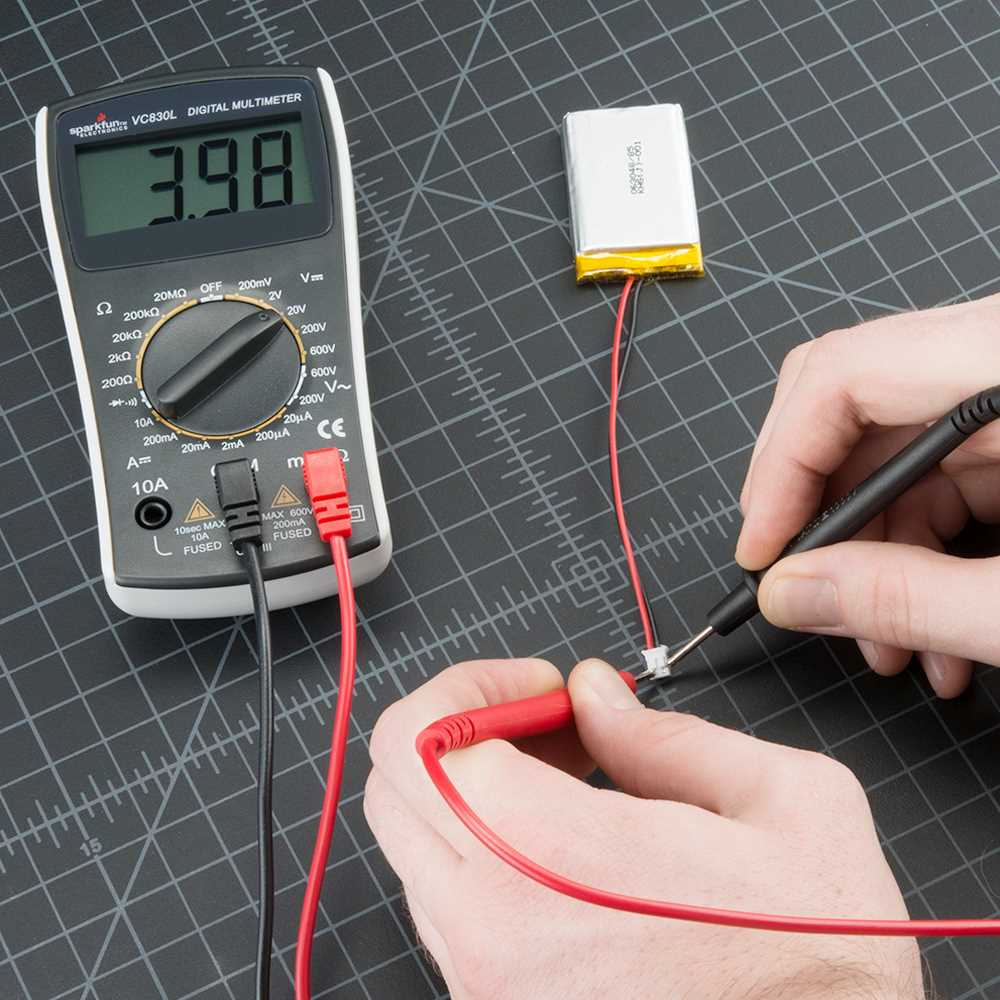

How to Measure Voltage with a Measurement Tool

Measuring voltage is one of the most fundamental tasks when using an electrical testing device. Voltage represents the potential difference between two points in a circuit, and accurately measuring it allows you to assess whether a circuit is operating within the expected parameters. Whether you’re testing a power supply or diagnosing an issue in a circuit, understanding how to correctly measure voltage is essential for any technician or engineer.

Follow these steps to measure voltage accurately:

- Set the Tool to the Voltage Mode: Before you begin, ensure the device is set to the correct mode for measuring voltage. Choose between alternating current (AC) or direct current (DC) depending on the circuit you’re testing.

- Connect the Probes: Insert the probes into the appropriate ports on the device. The red probe should be inserted into the positive port, while the black probe goes into the common (negative) port.

- Position the Probes on the Circuit: Place the red (positive) probe on the point where you want to measure voltage, and the black (negative) probe on a ground or reference point. Ensure both probes make good contact with the circuit.

- Read the Display: Once the probes are in place, observe the reading on the display. This shows the voltage at that point in the circuit. Make sure the reading aligns with the expected voltage for the system you’re testing.

- Check the Range: If the reading seems too high or too low, check the device’s range settings. Adjust the range if necessary to ensure accurate measurement.

By following these steps, you can confidently measure voltage in a variety of electrical systems. Proper use of the tool will allow you to diagnose issues, verify voltage levels, and ensure the safe operation of your equipment.

Understanding Current and Resistance Readings

When working with electrical systems, understanding how to interpret current and resistance readings is essential for diagnosing issues and ensuring the system operates correctly. Current represents the flow of electricity, while resistance indicates how much a component resists the flow of electricity. Accurately measuring both is key to assessing the functionality and health of circuits.

Each reading provides important insights into the state of a system. Current readings tell you whether there is a sufficient flow of electricity, while resistance readings help identify faulty components or potential short circuits. Knowing how to read and interpret these values can prevent malfunctions and improve the overall performance of electronic systems.

| Measurement Type | Description | Common Use Cases |

|---|---|---|

| Current | Measures the flow of electricity through a circuit. | Checking battery health, troubleshooting circuit functionality, verifying power supply levels. |

| Resistance | Indicates how much a component resists the flow of current. | Identifying broken or shorted components, measuring circuit continuity, detecting faulty wires. |

In practice, it’s important to know the expected ranges for current and resistance in a given circuit. High or low readings can indicate problems such as faulty wiring, damaged components, or an incorrect power supply. Understanding these values and knowing how to interpret them will enable you to troubleshoot issues efficiently and ensure the system operates as intended.

Essential Measurement Tool Safety Tips

When using an electrical testing device, safety should always be the top priority. These tools are designed to handle a variety of electrical measurements, but improper usage can lead to accidents, damage to equipment, or personal injury. It is crucial to follow safety guidelines to minimize risks while performing tests and diagnostics.

Here are some key safety practices to keep in mind when using electrical testing devices:

- Always Check the Tool’s Settings: Before taking any measurements, ensure the tool is set to the correct mode (voltage, current, or resistance) and that the range is appropriate for the circuit you’re testing.

- Inspect the Probes and Leads: Before each use, inspect the probes and leads for any signs of wear or damage. Frayed cables or exposed wires can lead to electric shock or short circuits.

- Use Proper Contact Points: Ensure that you make contact with the correct points on the circuit. Never touch the probes with bare hands while measuring high-voltage circuits to avoid electric shock.

- Disconnect Power When Possible: When measuring resistance or continuity, disconnect the power supply to avoid damage to the tool or shock hazards.

- Be Mindful of High Voltage: Exercise extreme caution when working with high-voltage circuits. Use appropriate protective gear and keep a safe distance from live wires.

- Follow Manufacturer’s Instructions: Always adhere to the safety guidelines provided by the manufacturer. These instructions are designed to ensure safe and efficient use of the tool.

By following these essential safety tips, you can reduce the risk of accidents and ensure the safe use of your testing equipment. Whether you are troubleshooting a circuit or verifying system functionality, maintaining safety standards is key to successful and secure measurements.

Calibration Fundamentals for Electrical Testing Tools

Accurate readings are essential when working with electrical measurement devices. Over time, the tool’s internal components may drift, causing inaccuracies in measurements. Calibration is the process of adjusting the device to ensure its readings are correct, which is crucial for maintaining reliability and consistency in testing results. Regular calibration is necessary to ensure that the tool performs to its highest standards and provides trustworthy measurements.

Calibration involves comparing the tool’s readings against known reference standards and making adjustments to correct any deviations. This process helps eliminate errors due to environmental changes, wear and tear, or other factors that can affect the device’s performance. Proper calibration ensures that the device continues to function accurately, making it an indispensable part of regular maintenance.

Here are the key steps in the calibration process:

- Choose the Right Calibration Standard: Use a high-precision reference device that has been calibrated to known standards. This will ensure your measurements are accurate and reliable.

- Perform Zeroing: Before performing any calibration, make sure the tool is set to zero when measuring a reference point that should not produce any reading, such as an open circuit.

- Compare Readings: Take measurements with the tool and compare them with the reference standards. Record any discrepancies in the readings.

- Adjust the Tool: If there is a significant difference between the tool’s readings and the reference, make the necessary adjustments as per the manufacturer’s guidelines.

- Verify Accuracy: After adjustments, perform the measurements again to verify that the device now reads accurately and consistently.

Regular calibration is essential to ensure that your electrical testing device continues to perform at its best, providing reliable results every time. Whether for routine use or critical diagnostic tasks, maintaining an accurately calibrated tool is vital for achieving precise and dependable measurements.

Interpreting Measurement Tool Display Results

Understanding the readings on a measurement tool’s display is crucial for effective troubleshooting and analysis. The numbers shown on the screen represent specific electrical parameters like voltage, current, and resistance, which provide valuable insights into the system being tested. Correctly interpreting these results ensures you can make informed decisions and accurately diagnose issues within the circuit.

The display typically shows a numerical value along with a unit of measurement, such as volts (V), amperes (A), or ohms (Ω). Additionally, some devices may show special symbols or indicators that help clarify the measurement type or alert you to potential problems. Understanding how to read these results and recognizing what they mean in the context of the circuit you’re testing is essential for proper analysis.

Here are some key factors to consider when interpreting display results:

- Value and Unit: The numerical value indicates the magnitude of the measured parameter, while the unit (V, A, Ω) specifies what is being measured. Always ensure that the unit matches the expected value for your testing purposes.

- Decimal Points: Many displays show values with decimal points, which are important for accuracy. For example, a reading of 12.34 V is more precise than just 12 V, and small changes can indicate issues that need attention.

- Overload Indication: If the measurement tool is overloaded, it may display an “OL” or similar warning. This indicates that the value exceeds the maximum range the device can measure, which may require you to adjust the settings or use a different measurement range.

- Negative Readings: A negative value may appear when the polarity is reversed, or the probe is connected to the wrong side of the circuit. Always check probe connections if you see unexpected negative values.

- Continuity and Resistance: When measuring continuity or resistance, a display showing a near-zero value typically indicates a closed or continuous circuit, while a very high value or “OL” indicates an open circuit.

By carefully analyzing the data presented on the tool’s display, you can gain a deeper understanding of the system under test. Recognizing the patterns and interpreting the results accurately will help you troubleshoot more effectively and make informed decisions about repairs or adjustments.

Practical Applications of Measurement Tool Tests

Measurement devices are essential tools for diagnosing electrical systems, and their applications span a wide range of industries. From troubleshooting home appliances to performing detailed circuit analysis, these tools allow users to gather valuable data that informs repairs, installations, and maintenance tasks. Knowing how to use these tools effectively opens the door to countless practical applications in both professional and DIY settings.

In this section, we will explore some common, real-world uses for measurement tests and how they help maintain electrical systems’ functionality and safety:

- Checking Battery Voltage: One of the simplest applications is measuring battery voltage. Whether it’s for a car battery or a household device, testing voltage helps you determine if the power source is functional or needs replacing.

- Testing Household Wiring: Electrical issues in the home can often be traced back to faulty wiring. By testing outlets and switches for continuity and voltage, users can identify potential issues like short circuits or dead outlets.

- Inspecting Fuse Integrity: Fuses protect electrical systems from overloads, but they can blow over time. Using a measurement tool to check resistance can confirm whether a fuse is still functional or needs to be replaced.

- Automotive Diagnostics: In the automotive world, these devices are used to check components like the alternator, starter motor, and sensors. Checking voltage, current, and continuity can help pinpoint issues in a vehicle’s electrical system.

- Monitoring Circuit Health: When testing complex circuits, these tools can help determine if components like resistors, capacitors, and diodes are functioning within their rated specifications, ensuring the circuit operates as intended.

- Measuring Current in Appliances: When diagnosing faulty home appliances, measuring current can reveal whether an appliance is drawing too much power, which could indicate a malfunction or electrical hazard.

By mastering these practical applications, users can address a broad range of electrical issues, enhance their troubleshooting skills, and ensure systems remain safe and efficient. Whether you’re maintaining your home or working on complex electrical equipment, these tests play an essential role in everyday electrical diagnostics.

Tips for Preparing for the Final Assessment

Preparation is key to success when approaching any evaluation, especially one that involves hands-on skills and technical knowledge. The more familiar you are with the tools, methods, and concepts, the better you’ll be able to perform when it counts. A solid preparation plan will not only boost your confidence but also improve your ability to solve problems efficiently during the test.

Here are some effective strategies to help you prepare for the assessment:

Review Key Concepts and Functions

Before diving into practical application, ensure that you have a strong understanding of the fundamental principles. Brush up on the core concepts such as voltage, current, and resistance, and how to measure them accurately. Pay attention to the different settings and modes available, as well as what each one is used for. Understanding the theory behind each test will help you interpret results correctly and avoid common mistakes during the assessment.

Practice Hands-On Skills

The best way to ensure you can perform well during the practical portion is through hands-on practice. Set up small test circuits, check various components, and practice measuring voltage, current, and resistance in different environments. The more you practice, the more familiar you’ll become with reading displays, adjusting settings, and identifying problems in the system you’re testing. Time yourself to ensure that you can complete the tasks efficiently and without hesitation.

In addition to reviewing theory and practicing tests, make sure you understand the safety protocols and proper usage of all tools. Familiarizing yourself with both the theoretical and practical aspects of the subject will prepare you for any challenge presented in the final assessment.

Common Mistakes to Avoid in Testing

When working with electrical measurements, it’s easy to make errors that can compromise the accuracy of your results or even lead to damage to the equipment. Knowing the common pitfalls and learning how to avoid them will ensure that your testing is both safe and effective. By staying mindful of these frequent mistakes, you can improve the reliability of your results and make the most of your tools.

Incorrect Settings

One of the most common errors during testing is using the wrong settings on the device. For instance, selecting the incorrect measurement mode–such as resistance instead of voltage–can lead to inaccurate readings or even damage to the tool. Always double-check the settings before beginning the test. It’s also important to verify the range setting to ensure it’s appropriate for the voltage, current, or resistance you’re measuring.

Improper Connection and Probing

Another frequent mistake is failing to connect the test leads correctly. Reversing the probes or making improper contact with the test points can result in misleading readings. Always ensure the probes are securely connected to the correct terminals and make good contact with the circuit points. Avoid touching the probes with bare hands, as it may affect the measurement or lead to inaccurate results.

To avoid these mistakes, develop a routine for each test and ensure you fully understand the tool’s functions. Taking the time to prepare and carefully review each step will help ensure that your testing is both precise and safe.

Reviewing Battery and Fuse Testing

Testing batteries and fuses is a critical part of ensuring that electrical systems are functioning properly. Batteries provide the necessary power to many devices, while fuses protect circuits from overloads and short circuits. Being able to properly assess the status of these components is essential for troubleshooting and maintaining electronic systems. This section covers the basics of testing batteries and fuses, including what to look for and how to interpret results accurately.

Battery Testing

To test a battery, it’s essential to measure its voltage and ensure it falls within the acceptable range for its type. Low or dead batteries can cause devices to malfunction, and checking their voltage helps determine if a replacement is necessary. Here’s how to perform a basic battery check:

| Battery Type | Expected Voltage Range |

|---|---|

| AA | 1.5V |

| 9V | 9V |

| 12V (Car Battery) | 12.6V |

When testing, ensure that the test leads are placed correctly, with the positive lead on the positive terminal of the battery and the negative lead on the negative terminal. If the voltage is lower than expected, the battery may need to be replaced.

Fuse Testing

Fuses serve as safety components that prevent circuits from being damaged by excessive current. A blown fuse can stop a device from working entirely. To test a fuse, you need to check for continuity. A functioning fuse will allow current to pass through, while a blown fuse will not. Here’s how you can test a fuse:

- Set the tester to continuity mode or resistance mode.

- Place the test leads on both ends of the fuse.

- If the fuse is intact, the tester should beep or show a low resistance reading.

- If the fuse is blown, the tester will show no continuity or a very high resistance reading.

Regularly checking the condition of both batteries and fuses will help ensure that the equipment is functioning optimally and that no issues are overlooked.

Interpreting Measurement Data Accurately

Accurately interpreting measurement results is key to troubleshooting and diagnosing issues in electrical systems. Whether you’re checking voltage, current, or resistance, understanding the numbers displayed is crucial for making informed decisions. Proper analysis ensures that problems are identified correctly and that the necessary actions are taken to resolve them. In this section, we will explore how to interpret measurement data with precision, highlighting common pitfalls and best practices.

Understanding Units and Ranges

Each measurement type–whether it’s voltage, current, or resistance–has specific units associated with it. It’s important to first understand these units and their acceptable ranges before interpreting the results. For instance, voltage is typically measured in volts (V), current in amperes (A), and resistance in ohms (Ω). Understanding the expected values for each test is essential for accurate analysis.

It’s also important to consider the range setting on your device. Many testing tools have multiple range options that automatically adjust depending on the signal being measured. If the range is set too low, you may get an inaccurate reading, while a range set too high could make it harder to see subtle variations.

Interpreting Readings Based on Expected Values

Once you know the units and have selected the proper range, it’s time to interpret the measurement. For example, when testing the voltage of a battery, you should be familiar with the expected voltage for that specific battery type. A 1.5V AA battery should show close to 1.5V when measured, while a 12V car battery should typically show 12.6V if it’s fully charged.

For current measurements, ensure that you understand the expected current flow in the circuit you are testing. For instance, in household circuits, the current flow might be in the range of a few amps, but higher currents could indicate a fault. Similarly, for resistance, any reading close to zero indicates a short circuit, while infinite resistance suggests an open circuit.

By knowing the expected values for the components you are testing, you’ll be able to quickly identify any discrepancies and determine whether the readings indicate a fault or if the circuit is functioning as expected.

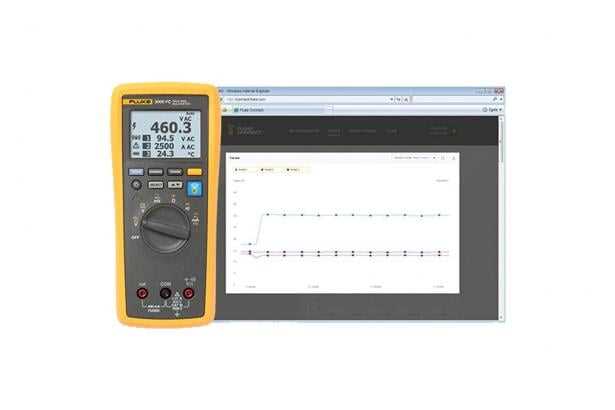

Advanced Features of Measurement Devices

Modern testing tools come equipped with a range of advanced features designed to enhance precision, ease of use, and troubleshooting capabilities. These additional functionalities are particularly beneficial for users who require more than just basic readings. Understanding these advanced capabilities can greatly improve the efficiency and accuracy of measurements, especially when dealing with complex or specialized tasks. This section will explore some of the key features found in high-end measurement devices, helping users to make the most out of their equipment.

Auto-Ranging for Effortless Measurement

One of the most useful features in advanced testing equipment is auto-ranging. This function automatically adjusts the measurement range depending on the signal being tested. With auto-ranging, users no longer need to manually select the appropriate range for each measurement, reducing the chances of errors. This is particularly helpful when testing unknown values, as it saves time and ensures accurate results without the need for constant adjustments.

Data Hold and Recording Functions

Another advanced feature is the data hold function, which allows users to freeze the displayed reading. This is invaluable when you need to take a reading but can’t immediately write it down or need to view the value at a later time. Some models also offer data logging capabilities, allowing for continuous measurement over time, which is perfect for monitoring trends or conducting long-term tests.

Additionally, many devices come with built-in memory storage, enabling users to save specific readings for future reference. This function is especially useful when conducting multiple tests and comparing results, as it minimizes the need to take repeated measurements.

How to Troubleshoot Measurement Device Issues

When working with precision tools, occasional malfunctions or inaccuracies are bound to occur. Understanding how to diagnose and fix these issues is essential for ensuring reliable performance. Whether you’re dealing with incorrect readings, a non-responsive display, or other functional problems, troubleshooting is an important skill. This section will guide you through common issues and their solutions to help you maintain your device in top condition.

Common Problems and How to Fix Them

One of the most frequent issues users face is inaccurate or fluctuating readings. This could be due to improper settings, such as incorrect range selection, or issues with the test leads or connections. The first step in resolving this problem is to check that the tool is properly set for the specific measurement you’re attempting, and that the leads are securely connected to both the device and the circuit.

If the readings continue to be erratic, ensure that the battery is not running low, as this can cause performance issues. Replacing the battery may resolve the problem, as many tools experience reduced accuracy when the power is insufficient.

Display and Power Issues

Another common problem is a blank or flickering display. This can be caused by a malfunctioning screen, loose wiring, or a depleted battery. In cases where the display is not showing anything, start by checking the battery and replacing it if necessary. If the display is still unresponsive, inspect the internal connections or consider consulting the user manual for troubleshooting tips specific to your model.

Finally, if your device stops turning on altogether, a faulty fuse might be to blame. Many advanced tools contain fuses that protect against overloads. Check the fuse and replace it if it’s blown, as this is often a simple fix for devices that fail to power up.

Using the Measurement Tool for Professional Projects

For professionals in fields like electronics, engineering, and troubleshooting, having the right equipment is key to ensuring high-quality results. Measurement tools are invaluable when diagnosing, testing, and verifying electrical systems. Whether you’re working on intricate circuit designs or conducting in-depth analysis, using the right device can make the difference between success and failure. Here’s how you can maximize the effectiveness of your tool in various professional environments.

Key Applications in Professional Work

When applying a measurement tool to professional tasks, it is essential to leverage its full range of capabilities. Below are several areas where these devices are most commonly used in professional settings:

- Testing Circuits: Professionals use the device to check voltage, current, and resistance in circuits to ensure everything is functioning within expected parameters.

- Diagnostic Work: When troubleshooting malfunctioning systems, it’s crucial to identify faulty components. This tool helps pinpoint issues such as short circuits, broken connections, or improperly functioning components.

- Calibration: The device is vital in calibrating systems to ensure they are running accurately. This is particularly important for sensitive instruments in industries such as manufacturing or laboratory research.

- Quality Control: Before equipment is shipped or deployed, quality checks are done using these devices to verify that all measurements are within specifications.

Advanced Tips for Maximizing Performance

To get the most out of your device, here are a few expert tips that can help during high-level projects:

- Regular Calibration: Ensure the tool is calibrated regularly to avoid discrepancies that could impact measurements, especially when working with precise systems.

- Use the Right Settings: Always select the correct range and measurement type based on the task at hand. Using the wrong settings could result in inaccurate readings or even damage to the tool.

- Maintain the Tool: Keep the device clean and store it properly to ensure its longevity and performance. This is especially important in high-use environments.

- Documentation: Record the test results carefully for future reference, especially when troubleshooting or diagnosing complex issues over time.

By following these guidelines, professionals can make sure their work is precise, efficient, and free from errors. Using the right equipment with knowledge and skill is critical for achieving reliable outcomes in any technical field.