Preparing for a workplace safety course requires a thorough understanding of essential principles that enhance well-being in professional environments. Acquiring this knowledge equips individuals with the tools needed to navigate and address potential challenges effectively.

This guide focuses on essential preparation strategies, commonly explored topics, and practical resources to aid learners. It provides insights into critical concepts and their practical applications to improve comprehension and ensure readiness.

Effective study techniques and practice materials can significantly improve understanding and retention. By following a structured approach, learners can approach assessments with confidence and clarity.

Osha 10 General Industry Overview

Understanding workplace safety protocols is crucial for creating secure and efficient environments. These programs emphasize the importance of hazard identification, risk reduction, and proper procedures to ensure the well-being of all employees.

Key Components of Workplace Training

Training initiatives typically cover a range of topics, from identifying potential risks to implementing preventative measures. Participants gain valuable insights into maintaining safe practices and adhering to established regulations, which are vital for fostering a culture of safety.

Impact on Professional Environments

Adopting these practices not only reduces accidents but also promotes productivity and morale. By equipping individuals with the necessary knowledge and tools, organizations can create environments that prioritize both safety and efficiency.

Key Topics Covered in the Training

Workplace safety education focuses on equipping participants with the essential knowledge to recognize potential hazards and implement effective solutions. These lessons build a strong foundation for promoting safe and efficient practices in various settings.

Identifying Workplace Hazards

A significant aspect of the program is learning to identify risks that could compromise safety. Participants explore different types of hazards, ranging from physical to environmental, and discover strategies to mitigate them effectively.

Implementing Preventative Measures

Another core element of the curriculum involves adopting precautionary steps to reduce incidents. This includes understanding proper equipment use, maintaining clear communication, and following established guidelines to enhance overall security.

Understanding Workplace Safety Standards

Creating a secure work environment relies on adhering to well-established rules that prioritize the health and safety of all individuals. These standards are designed to minimize risks and ensure smooth operations across different sectors.

- Promoting hazard awareness: Recognizing and addressing potential dangers before they lead to incidents is a key focus of these guidelines.

- Encouraging proper practices: From using equipment correctly to maintaining clear workspaces, safe habits form the foundation of compliance.

- Ensuring accountability: Assigning responsibilities helps in monitoring safety measures and maintaining consistency throughout the workplace.

By understanding and implementing these principles, organizations can foster a proactive culture where safety becomes an integral part of daily operations.

Importance of Workplace Safety Certification

Achieving certification in workplace safety demonstrates a commitment to protecting employees and maintaining high standards of operational integrity. It reflects an individual’s or organization’s dedication to fostering a secure and productive environment.

Enhancing Employee Knowledge

Certification programs provide workers with practical skills and a deeper understanding of safety protocols. These courses help employees identify risks, respond effectively, and contribute to a safer workspace.

Boosting Organizational Reputation

For companies, certified staff signify a proactive approach to workplace security. This can enhance credibility, attract clients who value safe practices, and reduce liability in case of incidents.

By prioritizing training and certifications, individuals and businesses alike benefit from reduced risks and a stronger culture of safety.

Preparation Strategies for Success

Achieving success in any assessment requires focused preparation. By organizing study materials effectively and adopting proven techniques, individuals can boost their confidence and improve their performance.

Effective Study Organization

- Create a study plan: Break down topics into manageable sections and allocate specific times for each one.

- Utilize diverse resources: Combine textbooks, online resources, and practice tests to enhance understanding.

- Review past materials: Go through notes, quizzes, and any available mock tests to reinforce key concepts.

Building Productive Study Habits

- Prioritize important topics: Focus on areas with the most weight or those that are more challenging.

- Stay consistent: Dedicate time each day to review and practice regularly rather than cramming.

- Take effective breaks: Short, frequent breaks can maintain concentration and prevent burnout.

Implementing these strategies will create a structured approach to studying, helping to boost understanding and improve outcomes.

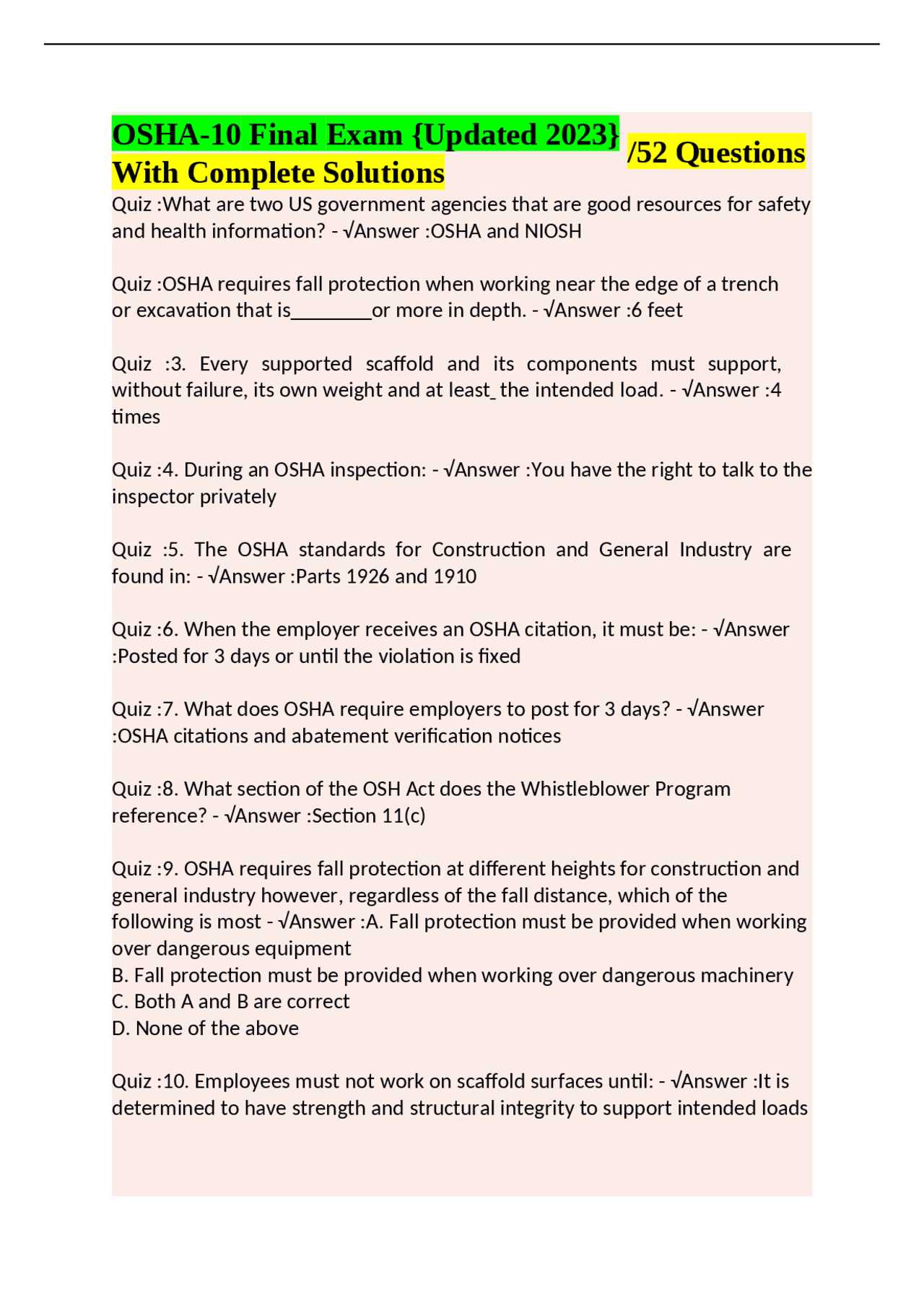

Common Questions in the Assessment

When preparing for a professional assessment, it’s essential to be aware of the types of questions typically asked. Understanding the common themes and topics will help streamline your study process and increase your confidence during the test.

Frequently Asked Topics

- Safety regulations: Questions often focus on key guidelines for maintaining a safe work environment.

- Risk management: Expect queries related to identifying potential hazards and how to mitigate them.

- Emergency procedures: Many questions address actions to take in case of accidents or unexpected situations.

Practical Scenario Questions

- Real-life applications: Questions may test your ability to apply learned concepts in practical work situations.

- Problem-solving: Some questions present hypothetical situations requiring you to determine the best course of action based on your knowledge.

By familiarizing yourself with these types of questions, you can better prepare and approach the assessment with a clear understanding of what to expect.

How to Interpret Assessment Questions

Understanding the wording of assessment questions is crucial to providing accurate responses. Often, questions are designed to test both your knowledge and ability to think critically about the material. To answer effectively, it’s essential to break down the question and focus on its key components.

Start by carefully reading the question to understand what it is asking. Look for keywords that highlight the focus, such as “define,” “explain,” or “compare.” Pay attention to any terms that specify what you need to address, such as examples or particular aspects of a concept.

Additionally, consider any context provided in the question, which may help you determine the best approach. Sometimes, questions are framed to present a real-world situation, which requires applying theoretical knowledge to solve a problem.

By following these steps, you will be better equipped to interpret questions accurately and formulate thoughtful, well-supported responses during your assessment.

Effective Study Resources and Tools

Preparing for an assessment requires the right resources and tools to effectively absorb and retain information. A wide variety of materials are available to help individuals better understand the necessary concepts and ensure readiness for their evaluation. Choosing the right resources can make a significant difference in your ability to succeed.

Recommended Study Materials

There are several key study resources that can aid in preparation:

- Textbooks and Guides: Comprehensive textbooks provide in-depth coverage of the material, helping to clarify difficult topics.

- Practice Tests: Completing practice tests helps familiarize you with the format of the questions and the kind of knowledge that is required.

- Study Groups: Collaborating with peers can enhance learning by offering diverse perspectives and discussing complex ideas.

- Online Resources: Educational websites and platforms provide valuable insights, tutorials, and videos for visual learners.

Study Tools for Success

In addition to resources, various study tools can streamline preparation:

- Flashcards: These can help reinforce key terms and concepts quickly and effectively.

- Time Management Apps: Organize study sessions and allocate time to focus on specific topics for better efficiency.

- Note-taking Software: Digital notes allow for easy access and organization of important points during study sessions.

By utilizing a combination of these resources and tools, you can enhance your learning experience and improve your chances of success in your assessment.

Tips for Retaining Safety Knowledge

Retaining safety information is crucial for maintaining a secure and efficient work environment. Knowledge of safety practices must be continuously reinforced to ensure individuals can act promptly and effectively in any situation. The key to retaining this vital information lies in using strategies that promote long-term memory and practical application.

Effective Retention Techniques

Several techniques can help improve memory retention when learning safety protocols:

- Active Recall: Regularly testing yourself on the material helps strengthen memory by actively engaging with the content.

- Spaced Repetition: Repeating information over increasing intervals improves long-term retention.

- Visualization: Creating mental images of safety scenarios can help you remember key procedures more clearly.

- Practical Application: Regularly practicing safety procedures in real-life situations strengthens your ability to recall and apply them when needed.

How to Stay Consistent

To ensure consistent retention, use the following methods:

| Method | Benefit |

|---|---|

| Review Regularly | Reinforces knowledge and helps keep safety practices fresh in your mind. |

| Engage in Group Discussions | Collaborating with peers helps reinforce concepts and provides different perspectives. |

| Use Safety Reminders | Visual reminders, like posters or checklists, ensure that important safety points are always within sight. |

By combining these methods, you can effectively retain safety knowledge and apply it when necessary, ensuring a safer work environment for all.

Mock Tests and Practice Assessments

Engaging in practice tests and mock assessments plays a vital role in preparing for any evaluation. These tools simulate the actual conditions of an assessment, allowing individuals to familiarize themselves with the format and types of questions they will face. Through regular practice, participants can identify their strengths and areas needing improvement, ensuring a more confident and prepared approach to the actual assessment.

Benefits of Practice Tests

Taking mock tests offers several advantages that enhance readiness and confidence:

- Familiarization with Test Structure: Understanding the format helps reduce anxiety during the actual assessment, making it easier to manage time effectively.

- Improved Time Management: Practice assessments allow individuals to hone their ability to allocate time wisely, ensuring all questions are addressed within the given timeframe.

- Self-Assessment: Regularly practicing allows individuals to identify areas that require further attention, facilitating targeted study and improvement.

- Confidence Boost: Repeated exposure to questions and topics builds confidence, making individuals feel more prepared to tackle the real assessment.

How to Maximize Practice Assessments

To gain the most from mock tests, consider implementing these strategies:

| Strategy | Benefit |

|---|---|

| Simulate Real Conditions | Taking the test under time constraints and in a quiet environment mirrors the actual assessment experience, enhancing preparedness. |

| Review Mistakes Thoroughly | Understanding why an answer was wrong helps address knowledge gaps and prevents similar errors in the future. |

| Use a Variety of Sources | Using different practice materials exposes individuals to a wide range of question types and scenarios, improving adaptability. |

By integrating mock tests and assessments into the study routine, individuals can greatly enhance their chances of success, boosting both knowledge and test-taking skills.

Analyzing Workplace Hazards and Solutions

Understanding the potential risks present in various work environments is crucial for maintaining a safe and productive atmosphere. Identifying hazards, evaluating their potential impact, and implementing appropriate solutions help in minimizing accidents and improving overall safety standards. Effective hazard analysis ensures that workers can perform their tasks without the threat of harm while fostering a culture of prevention and awareness.

Workplace hazards come in many forms, including physical, chemical, biological, and ergonomic risks. Each category presents unique challenges that require specific safety measures. Through systematic analysis and risk assessment, it is possible to mitigate these dangers and create a safer working environment.

Common workplace hazards include:

- Physical Hazards: These include risks such as machinery malfunctions, falls, and exposure to extreme temperatures.

- Chemical Hazards: These hazards stem from exposure to toxic substances like gases, fumes, and liquids that can cause harm to health.

- Biological Hazards: In some settings, workers may be exposed to harmful bacteria, viruses, or other pathogens.

- Ergonomic Hazards: These arise from repetitive movements, poor workstation design, or lifting heavy objects that can lead to long-term injuries.

Once hazards are identified, effective solutions can be implemented to address them:

- Engineering Controls: These include installing protective barriers, improving ventilation systems, or redesigning tools and equipment to reduce risk.

- Administrative Controls: Developing safety protocols, providing training, and enforcing safety regulations help to minimize exposure to hazards.

- PPE (Personal Protective Equipment): When hazards cannot be eliminated, providing workers with appropriate safety gear, such as gloves, helmets, and respirators, becomes essential.

By regularly assessing potential risks and implementing preventive measures, organizations can safeguard their employees and create a safer work environment for all involved.

Key Elements of Workplace Safety Compliance

Adhering to workplace safety standards is essential for ensuring the well-being of all employees and maintaining a safe environment. Compliance involves understanding specific regulations and implementing systems that address hazards and risks effectively. Establishing clear procedures and practices for safety can prevent accidents, reduce injuries, and create a culture of responsibility within an organization.

Essential Components of Compliance

Compliance with safety regulations involves several crucial elements, each designed to address specific aspects of workplace safety. These components must be carefully integrated into daily operations to ensure a holistic approach to risk management.

- Risk Assessment: Identifying potential hazards in the workplace is the first step in ensuring safety. Regular evaluations help to uncover hidden risks, whether physical, chemical, or environmental.

- Training Programs: Educating employees about safety procedures and proper practices is vital. Ongoing training ensures that everyone is aware of potential dangers and knows how to respond appropriately in emergency situations.

- Clear Policies and Procedures: Establishing written protocols for handling various hazards ensures that all workers know the proper steps to take in any situation. These procedures should be regularly updated and communicated to employees.

- Inspection and Maintenance: Regular inspections of equipment and the work environment help identify issues before they become significant problems. Timely maintenance prevents malfunctioning tools and machinery, which could pose risks to workers.

Enforcement and Accountability

Compliance is not only about setting up procedures but also about holding everyone accountable. Managers and supervisors play a crucial role in enforcing safety standards, ensuring adherence to regulations, and fostering a culture of vigilance.

- Monitoring and Reporting: Continuous monitoring of workplace safety practices allows for real-time identification of non-compliance or unsafe behavior. Prompt reporting mechanisms ensure that issues are addressed quickly.

- Disciplinary Actions: Ensuring that non-compliance is met wi

Test Responses and Explanations

This section provides detailed insights into the correct responses for each scenario, explaining why these choices are appropriate in the context of maintaining a safe working environment. Understanding these justifications helps reinforce the key principles that guide safety practices, ensuring preparedness for handling various workplace hazards effectively.

Explanation of Selections

The following table presents specific situations along with the recommended actions and the reasoning behind each decision. By breaking down each step, the goal is to clarify the importance of safety procedures and how they contribute to minimizing risks in the workplace.

Scenario Recommended Action Rationale Electrical Hazard Turn off the power immediately and notify the safety team Disabling the power prevents potential electric shocks or fire hazards, while notifying the safety team ensures professional handling of the issue. Slippery Floor Place caution signs and clean the affected area Warning signs alert individuals to the danger, while cleaning the floor helps avoid further accidents, maintaining a safer environment. Incorrect Protective Gear Ensure all personnel wear the required protective equipment Correct use of protective gear minimizes the risk of injury or exposure to hazardous materials, ensuring the safety of workers. Fundamental Safety Practices

The following safety principles are essential in maintaining a secure and hazard-free workplace:

- Hazard Identification: Recognizing potential dangers early on is crucial for preventing accidents and enabling prompt responses.

- Quick Response: Knowing the proper emergency procedures ensures that risks are mitigated and that individuals stay safe during unexpected situations.

- Ongoing Training: Regular safety training updates knowledge, helping workers stay informed and capable of responding to new challenges.

By comprehending the reasons behind these actions, individuals can make well-informed decisions, ensuring a safer working environment for all.

How to Apply Safety Principles Daily

Incorporating safety practices into everyday work routines is essential to prevent accidents and create a secure environment for everyone. Understanding the core principles of safety and making them part of daily activities can significantly reduce risks. The following guidelines explain how to integrate safety into everyday tasks effectively.

- Risk Assessment: Regularly evaluate your workspace for potential hazards. Identifying risks early allows for timely corrective measures.

- Proper Use of Equipment: Always use tools and machinery according to the manufacturer’s instructions. This ensures safe operation and reduces the chance of malfunctions.

- Clean and Organized Workspace: A tidy environment reduces the likelihood of accidents such as tripping or equipment failure. Keep work areas clear of clutter.

- Use of Protective Gear: Always wear the necessary protective equipment relevant to your tasks. This minimizes exposure to hazardous substances or situations.

- Effective Communication: Maintain clear communication with coworkers, especially when handling equipment or working in potentially hazardous areas. This helps prevent misunderstandings that could lead to accidents.

- Emergency Preparedness: Be familiar with emergency procedures. Know the locations of exits, fire extinguishers, and first-aid kits. Participate in drills to stay prepared for unexpected situations.

By adhering to these principles, workers can contribute to a safer environment, reducing injuries and promoting overall well-being. Implementing these practices consistently in day-to-day operations creates a culture of safety and care.

Updates in Regulations for 2025

The regulatory framework for workplace safety is continually evolving to address emerging risks and improve protections for workers. New updates to safety standards and guidelines ensure that companies remain compliant with the latest requirements and that workers are provided with the safest possible environment. Below are some of the key changes to be aware of in 2025.

Enhanced Protection for Workers

One of the significant updates this year focuses on strengthening protections for employees exposed to hazardous materials and environments. New regulations introduce stricter limits on exposure to toxic substances and mandatory health monitoring for workers in high-risk sectors. Employers will need to adopt additional safety protocols to comply with these changes.

Improved Reporting and Training Requirements

There is a notable emphasis on improving safety training and reporting systems. Organizations will be required to provide more frequent training sessions and documentation on safety practices. Additionally, new reporting standards have been implemented, encouraging more detailed records of workplace hazards and safety incidents to enhance transparency and facilitate faster responses to potential risks.

Regulation Change Impact Compliance Action Exposure Limits for Hazardous Materials Reduced permissible exposure limits for toxic substances Review and update risk assessments, enhance monitoring procedures Mandatory Health Monitoring Health checks required for workers in high-risk environments Implement health screening programs, track worker health over time Enhanced Reporting Standards Detailed incident reports to improve transparency Ensure all incidents are documented, train staff on new reporting guidelines These updates are designed to enhance the overall safety and well-being of workers, ensuring that safety protocols keep pace with evolving workplace challenges. Organizations must stay informed about these changes to avoid penalties and to create a safer working environment for all employees.

Common Mistakes During the Certification Process

When preparing for and taking certification assessments, it is easy to overlook certain details that can negatively impact performance. These mistakes can range from misinterpreting instructions to failing to manage time properly. Understanding these common pitfalls can help candidates avoid unnecessary errors and improve their chances of success. Below are some of the most frequent mistakes made during the certification process.

Mistake Description How to Avoid It Not Reading Instructions Carefully Candidates may rush through instructions or skip reading them altogether, leading to misunderstanding the requirements of each question. Take time to carefully read and understand the instructions for each section before proceeding. Poor Time Management Failing to manage time effectively can cause candidates to rush through questions, missing important details or leaving questions unanswered. Allocate specific time for each section and stick to it. If unsure about a question, move on and come back to it later. Overlooking Key Concepts Focusing too heavily on one area and neglecting other key topics can lead to missing questions related to these areas. Review all study materials and practice tests to ensure all areas are covered evenly. Second-Guessing Answers Changing an answer repeatedly without justification can lead to confusion and potentially incorrect responses. Trust your initial understanding and avoid overthinking. Review answers only if necessary. Avoiding these common mistakes will help ensure a smoother experience and better performance. Preparing thoroughly, managing time wisely, and staying focused on the task at hand are all key to achieving a successful outcome. Remember, careful preparation and practice are the best strategies to reduce mistakes and maximize your chances of success.

Benefits of Achieving Certification

Obtaining professional certification in safety practices brings numerous advantages to both individuals and organizations. It not only enhances knowledge and skills but also plays a crucial role in creating safer work environments. Here are several key benefits of achieving certification in safety management.

For Individuals

- Career Advancement: Certified professionals are often seen as more qualified and capable, opening doors to new career opportunities and higher-paying positions.

- Increased Knowledge: The process of becoming certified improves understanding of safety protocols, regulations, and best practices, leading to more informed decision-making in the workplace.

- Enhanced Job Security: Individuals with certifications are in higher demand, as companies prioritize safety and seek qualified professionals to maintain compliance with safety standards.

- Personal Satisfaction: Completing the certification process provides a sense of accomplishment and confidence in one’s ability to contribute to a safer workplace.

For Organizations

- Improved Workplace Safety: Certified employees help ensure that safety procedures are followed rigorously, reducing the risk of accidents and injuries.

- Compliance with Regulations: Organizations that have certified staff are better equipped to meet legal and regulatory safety requirements, avoiding penalties and legal issues.

- Enhanced Reputation: Businesses with certified personnel are viewed as more responsible and reliable, fostering trust with clients, partners, and regulatory bodies.

- Cost Savings: Fewer workplace accidents and injuries mean lower insurance premiums and reduced costs related to workers’ compensation and medical care.

Achieving certification not only benefits individuals by boosting their expertise and employability but also supports companies in maintaining safe and compliant work environments. The process offers long-term advantages that contribute to personal growth and organizational success.