Achieving proficiency in load handling and lifting operations requires mastering a variety of techniques and concepts. To succeed in this specialized field, understanding key principles is essential, especially when it comes to demonstrating your knowledge in a testing environment. Proper preparation and familiarization with common challenges play a significant role in passing the certification process.

Preparation is the foundation of success. Thoroughly reviewing the fundamental principles, safety regulations, and mathematical calculations involved in the industry ensures confidence when facing complex tasks. Whether you’re preparing for a theoretical portion or hands-on assessments, each component tests a critical aspect of the profession. Developing a systematic approach to problem-solving and recognizing potential risks will help you perform efficiently in any situation.

Throughout your preparation, it is important to understand the expectations and requirements of the certification process. This involves both practical and theoretical elements, each designed to verify your competency in safely managing heavy loads and equipment. Familiarizing yourself with typical scenarios and questions that may arise will give you a significant advantage and increase your chances of passing the assessment with flying colors.

Competent Rigger Final Exam Answers

When preparing for a certification in the field of load handling and lifting operations, it is crucial to understand the key areas that will be tested. Success depends on your ability to apply technical knowledge to real-world scenarios. Each question or task assesses your understanding of safety protocols, equipment handling, and problem-solving skills under pressure. Being well-prepared for all aspects of the assessment will ensure that you can meet industry standards and perform competently in the field.

Understanding Key Areas of Focus

In any certification process, there are several core areas that need to be mastered. These include equipment selection, proper rigging techniques, safety measures, and mathematical calculations for load capacities. By focusing on these essential topics, you can ensure that you are ready to tackle any situation presented in the assessment. Thoroughly reviewing each area and practicing your skills will give you the confidence needed to succeed.

Practical Preparation Tips

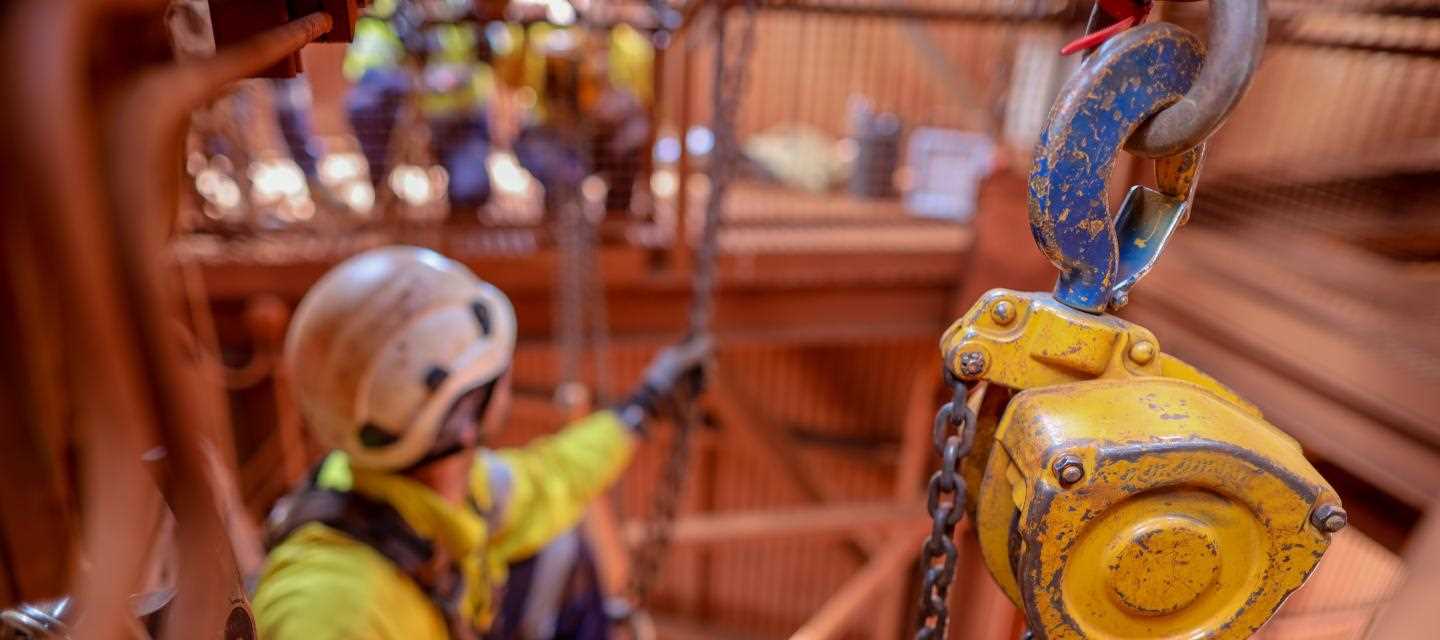

Practical training is as important as theoretical knowledge. Engaging in hands-on practice with lifting and rigging equipment is essential for building real-world skills. Understanding the physical aspects of load movement, securing loads, and working with a team is crucial to ensuring safety and efficiency on the job. By simulating potential challenges, you can better prepare yourself to face them during the certification process and in actual work situations.

Overview of the Rigger Certification

In the field of load handling and lifting, certification plays a critical role in ensuring that professionals possess the necessary skills and knowledge to perform tasks safely and efficiently. This process evaluates both theoretical understanding and practical abilities, validating competence in managing heavy equipment, securing loads, and following safety protocols. Successful completion of the certification process opens the door to career advancement and job opportunities in a highly specialized industry.

Core Areas of Certification

The certification typically covers several key areas, each of which plays a vital role in the safe execution of lifting operations. These include:

- Understanding rigging hardware and equipment

- Implementing safety measures during lifting operations

- Mathematical calculations for weight and load distribution

- Proper communication and teamwork during complex tasks

- Knowledge of relevant industry standards and regulations

Steps to Achieving Certification

Achieving certification requires meeting several important milestones, each designed to assess different aspects of the profession:

- Initial training and education on rigging techniques

- Hands-on experience working with lifting equipment

- Theoretical assessment of safety practices and operational procedures

- Practical tests that simulate real-world lifting scenarios

- Completion of ongoing professional development for continued competency

Key Topics for Rigger Final Exam

When preparing for certification in the field of lifting operations, there are several core areas of knowledge that must be mastered. These topics cover the essential skills and concepts needed to ensure safe and effective load handling, equipment usage, and adherence to industry standards. A comprehensive understanding of these areas will help candidates confidently approach the assessment process and demonstrate their proficiency in real-world scenarios.

Essential Areas of Focus

The following topics are fundamental to the certification process and are commonly tested:

- Types of rigging equipment and their proper use

- Load calculation and weight distribution

- Safety protocols for lifting and handling heavy objects

- Inspection procedures for rigging gear

- Communication skills and teamwork during lifting operations

- Understanding of regulations and industry standards

Practical and Theoretical Concepts

Preparation should include both theoretical knowledge and hands-on practice. Key areas to focus on include:

- Mathematical calculations for load capacities and angles

- Choosing the right rigging equipment based on the task

- Understanding the mechanics of load movement and stability

- Effective signaling and communication between team members

- Emergency procedures and problem-solving in critical situations

Understanding Rigging Techniques

Mastering the proper techniques for load handling is a crucial aspect of ensuring safe and effective lifting operations. Understanding the principles behind rigging and equipment usage can significantly impact the success of any operation. This includes knowing the right methods to secure loads, how to balance weight distribution, and the best practices for using rigging tools safely and efficiently.

Key Rigging Methods

There are several common rigging techniques that professionals must be familiar with. These methods are used to secure loads, prevent accidents, and ensure stability during lifting tasks:

- Double Wraps – Used to secure heavy loads by distributing weight evenly.

- Basket Hitch – Provides extra support when lifting a load with a sling.

- Choker Hitch – A method of securing a load tightly around the object.

- Single Leg Sling – A straightforward approach to lifting lighter loads using one sling.

- Bridle Hitch – Used for lifting with multiple slings to balance a load more evenly.

Important Considerations for Safe Rigging

While rigging techniques are essential for completing tasks, safety should always be the top priority. Key considerations include:

- Correctly assessing the weight and center of gravity of a load before choosing a rigging method.

- Regular inspection of rigging equipment for wear and tear to prevent failure during use.

- Choosing appropriate slings, hooks, and other rigging components based on the type of load.

- Using load charts to ensure safe lifting capacity for all equipment involved.

- Always maintaining clear communication with the team to prevent accidents during operations.

Common Mistakes to Avoid During the Exam

When undergoing the assessment process for load handling certification, it’s easy to make mistakes if you’re not fully prepared. Recognizing the common pitfalls and knowing how to avoid them can greatly increase your chances of success. From overlooking safety procedures to miscalculating load weights, the exam tests both your theoretical knowledge and practical skills. Understanding these common errors will help you approach the test with greater confidence and precision.

Typical Mistakes in the Assessment

Several common mistakes often occur during certification assessments. By being aware of them, you can take the necessary precautions to avoid these pitfalls:

- Overlooking Safety Protocols – Failing to prioritize safety can lead to errors or even accidents during the assessment.

- Incorrect Load Calculations – Misjudging the weight or load distribution can cause instability or failure during lifting tasks.

- Choosing the Wrong Equipment – Selecting inappropriate rigging tools or methods can lead to unsafe conditions.

- Failing to Communicate Clearly – Lack of clear communication with team members can result in miscoordination during lifting operations.

- Not Double-Checking Equipment – Failing to inspect rigging gear for damage or wear can cause equipment failure.

How to Prevent These Mistakes

Preventing errors during the assessment is all about preparation and attentiveness. Here are some helpful tips:

- Always review safety protocols thoroughly before starting any task.

- Ensure you understand how to perform load calculations and double-check your work.

- Be familiar with the types of equipment required for different lifting scenarios.

- Practice effective communication with your team, ensuring everyone is on the same page.

- Conduct a complete inspection of all rigging tools and equipment before beginning any lifting operation.

Preparing for the Practical Exam

Preparing for the hands-on portion of the certification process requires both practical skills and an understanding of safety protocols. The ability to perform tasks under real-world conditions will be assessed, making it essential to be familiar with the equipment, techniques, and procedures you will be tested on. Effective preparation includes not only practicing the necessary skills but also ensuring that you are comfortable under pressure and able to make quick, safe decisions.

Key Areas to Focus On

During the practical assessment, you will be expected to demonstrate proficiency in several key areas. It’s important to spend time on these fundamental aspects:

- Load Handling – Ensure that you are comfortable with lifting and securing different types of loads safely.

- Equipment Usage – Familiarize yourself with various rigging tools and their proper usage for different lifting tasks.

- Safety Procedures – Always prioritize safety by following proper protocols and inspecting all equipment before use.

- Team Coordination – Practice clear communication and coordination with team members to ensure smooth operations during the lift.

Tips for Effective Preparation

To excel during the practical assessment, consider the following preparation tips:

- Conduct mock assessments to simulate real lifting scenarios, helping you become more comfortable with the process.

- Review the equipment list and familiarize yourself with each item’s function and limitations.

- Focus on time management, ensuring you can complete tasks efficiently without compromising safety.

- Ask for feedback from instructors or experienced professionals to improve your technique and approach.

- Stay calm and composed, as pressure can often lead to mistakes. Practicing in high-stress environments can help you maintain focus.

Study Resources for Rigger Certification

Preparing for certification in the field of load handling requires access to the right study materials. Whether you are focusing on theory or practical skills, utilizing a variety of resources can help ensure a comprehensive understanding of the subject matter. From textbooks and online courses to hands-on practice and safety manuals, having a well-rounded set of tools at your disposal is key to success.

Study resources often include written guides, instructional videos, and practice assessments designed to enhance knowledge in areas like equipment handling, safety procedures, and load calculations. Additionally, seeking out feedback from experienced professionals can provide valuable insights into real-world applications and best practices.

Consider exploring the following types of resources during your preparation:

- Textbooks and Manuals – In-depth materials covering industry standards, safety protocols, and equipment specifications.

- Online Courses – Interactive learning platforms offering videos, quizzes, and certification preparation courses.

- Practice Tests – Simulated assessments to help you gauge your readiness and identify areas for improvement.

- Workshops and Training Programs – Hands-on courses that allow you to practice rigging techniques in a controlled environment.

- Safety Guidelines – Industry-specific safety manuals that outline best practices and regulatory standards.

Important Safety Protocols in Rigging

Safety is the cornerstone of any lifting operation. Adhering to proper safety protocols ensures the protection of both personnel and equipment, minimizing the risk of accidents and injuries. Understanding these protocols is essential for anyone involved in load handling, whether you are working directly with rigging gear or overseeing operations. Proper preparation and a clear understanding of safety standards are critical for the success of any lifting task.

Key Safety Guidelines

Several safety protocols must be followed to ensure a secure environment during lifting operations. These guidelines help to prevent accidents and ensure that the operation proceeds smoothly:

- Pre-Lift Inspections – Always inspect equipment before use, checking for wear, tear, or damage that could affect performance.

- Correct Load Calculation – Ensure that the weight and distribution of the load are calculated accurately to avoid overloading equipment.

- Clear Communication – Establish clear signals and communication methods between team members to avoid misunderstandings during the lift.

- Proper Use of Gear – Use the appropriate rigging equipment for the specific load, ensuring it is rated for the weight and task at hand.

- Fall Protection – Ensure that workers are properly secured with fall protection equipment when working at heights.

Emergency Procedures

Even with the best precautions, emergencies can happen. It is crucial to know how to handle unexpected situations. Key emergency protocols include:

- Evacuation Plans – Have a clear and practiced evacuation plan in place in case of an emergency.

- First Aid Training – Ensure that team members are trained in basic first aid and CPR to respond to injuries quickly.

- Immediate Hazard Assessment – Be able to assess and identify potential hazards quickly to minimize risks during lifting operations.

Common Rigger Exam Questions and Answers

During the certification assessment for load handling, candidates are typically asked a range of questions that test both theoretical knowledge and practical application. These questions are designed to assess an individual’s understanding of safety standards, equipment usage, and proper lifting techniques. Below are some of the most common questions you may encounter, along with their correct responses. Familiarizing yourself with these questions can help you prepare effectively for the certification process.

| Question | Answer |

|---|---|

| What is the safe working load (SWL) of lifting equipment? | The SWL is the maximum weight that a piece of lifting equipment can safely handle under specific conditions, without risk of failure. |

| How do you calculate the center of gravity for a load? | The center of gravity can be found by balancing the load on a flat surface or using calculations based on the load’s shape and weight distribution. |

| What safety precautions should be taken before a lift? | Ensure all equipment is inspected, verify the weight and balance of the load, and confirm that all team members are properly trained and understand their roles. |

| What is the purpose of tag lines during a lift? | Tag lines are used to control and guide the load during the lift, preventing it from spinning or shifting unexpectedly. |

| What should you do if you notice a fault in lifting equipment? | If a fault is identified, the equipment should be immediately taken out of service, reported to the appropriate supervisor, and not used until it has been properly inspected and repaired. |

Exam Format and Structure Explained

Understanding the layout and flow of the certification assessment is crucial for successful completion. The structure of the test is designed to evaluate both theoretical knowledge and practical skills in the field of load handling. By breaking down the format, you can effectively plan your approach, ensuring that you are well-prepared for each section of the assessment.

Written Section

The written portion of the assessment typically consists of multiple-choice, true/false, and short-answer questions. These questions are aimed at testing your understanding of safety standards, equipment handling, and regulatory requirements. Preparation for this section should focus on key concepts such as load calculations, lifting methods, and hazard identification.

Practical Assessment

The practical portion evaluates your ability to safely and efficiently apply techniques in a real-world scenario. You will be required to demonstrate various skills, such as:

- Correct use of lifting gear – Ensuring that all equipment is properly selected and used according to safety guidelines.

- Load handling – Safely rigging and moving loads with attention to balance, weight distribution, and hazard prevention.

- Team coordination – Communicating clearly with colleagues to ensure a smooth and safe operation.

Both sections are designed to assess different competencies, so it is important to balance your study efforts between theoretical knowledge and hands-on practice. A solid grasp of both will ensure a smooth progression through the certification process.

How to Master Rigging Calculations

Mastering the calculations involved in load handling is essential for anyone seeking to work safely and efficiently with lifting equipment. These calculations are used to determine the appropriate load limits, angles, and forces, ensuring that the lifting process is done within safe parameters. Gaining proficiency in these calculations is crucial for making informed decisions and preventing accidents. Here are some key aspects of mastering these calculations.

| Calculation Type | Purpose | Formula |

|---|---|---|

| Load Weight Calculation | Determines the total weight of the load to ensure equipment is used within its capacity. | Weight = Mass × Gravity |

| Load Distribution | Ensures that weight is evenly spread across the lifting gear to avoid overloading specific points. | Distributed Load = Total Weight ÷ Number of Support Points |

| Angle of Lift | Used to determine the correct lifting angle, which affects the load’s stability and safety. | Angle = tan-1(Vertical Height ÷ Horizontal Distance) |

| Safety Factor | Ensures the load is within safe limits by factoring in potential uncertainties such as wind or irregular surfaces. | Safety Factor = Load Capacity ÷ Applied Load |

By practicing these key calculations regularly and understanding their real-world application, you will be able to plan and execute lifts with confidence. It’s also essential to familiarize yourself with the formulas and techniques used in different situations to make quick, accurate calculations on the job site.

Best Practices for Load Handling

Proper load handling is critical to ensure both safety and efficiency during lifting operations. Following industry-standard practices can significantly reduce the risk of accidents and damage to equipment or materials. Mastering these techniques requires a strong understanding of both theoretical principles and practical applications. Below are some essential best practices that should always be followed during any load-handling task.

Pre-Operation Planning

Before beginning any lifting operation, it’s crucial to conduct thorough planning. This includes assessing the load’s weight, dimensions, and center of gravity. Additionally, selecting the appropriate lifting gear and ensuring it is in good condition is essential. Proper communication between all team members involved is necessary to ensure that everyone is on the same page about the lifting plan and procedures. Key planning steps include:

- Assessing load stability and distribution

- Verifying the lifting capacity of equipment

- Establishing a clear signal system for communication

Safe Lifting Techniques

Once the planning phase is complete, following safe lifting techniques is critical to prevent accidents. Always ensure that lifting equipment is correctly attached to the load and that all safety devices are engaged. The following practices should be observed during the lifting operation:

- Ensure a balanced load before lifting to prevent tipping

- Lift slowly and steadily to maintain control

- Never exceed the maximum load capacity of lifting equipment

- Monitor load stability throughout the operation

By adhering to these best practices, you can ensure that lifting operations are conducted efficiently and with a high level of safety, minimizing potential risks for workers and equipment alike.

Rigger Exam Tips from Experts

Successfully navigating the certification process requires not only theoretical knowledge but also practical insights into the specific challenges candidates may face. Experts in the field have shared valuable tips that can help streamline the preparation process and boost confidence when facing the assessment. These tips cover everything from study strategies to mental preparedness, ensuring that you are ready for every aspect of the evaluation.

Study Techniques for Success

Experts agree that a focused and systematic approach to studying is key. Rather than cramming, it’s important to break down complex topics into manageable segments. Prioritize understanding core concepts before diving into more advanced material. Some effective strategies include:

- Reviewing common terminology and industry-specific jargon

- Focusing on practical scenarios and real-life applications

- Using visual aids such as diagrams and charts to reinforce concepts

- Taking practice quizzes to simulate test conditions

Preparation for Practical Application

While theoretical knowledge is crucial, hands-on practice is equally important. Many candidates struggle with the application of concepts during the practical assessment. To excel in this area, experts recommend:

- Practicing load calculations and stability assessments regularly

- Familiarizing yourself with all the tools and equipment you’ll use on the job

- Rehearsing standard procedures to ensure quick, efficient execution under pressure

- Working with a mentor or colleague to refine your techniques

By incorporating these expert tips into your preparation, you can approach the certification process with greater confidence and efficiency, giving yourself the best possible chance for success.

Practical Skills You Need to Pass

To successfully complete the certification process, candidates must demonstrate proficiency in various hands-on skills that are critical in real-world operations. These skills not only test your understanding of theoretical concepts but also your ability to apply them safely and effectively in practice. Mastering these abilities will ensure that you are fully prepared for every aspect of the assessment. Below is an overview of the essential practical skills you should focus on.

Essential Practical Skills

There are several key areas in which you must demonstrate expertise to pass the practical portion of the certification. These include:

- Load Assessment and Calculation: Accurately calculating load weights, understanding the center of gravity, and ensuring that lifting equipment can handle the load safely.

- Equipment Handling: Properly selecting, inspecting, and using rigging tools and lifting devices such as slings, hooks, and pulleys.

- Safety Procedures: Following all safety protocols, including securing the area, maintaining clear communication, and ensuring that all safety gear is used correctly.

- Load Securement: Demonstrating how to securely fasten loads to lifting devices and checking for stability before lifting.

Key Techniques and Practices

In addition to these skills, there are specific techniques and practices that candidates must master to showcase their readiness. These include:

| Technique | Description |

|---|---|

| Proper Rigging of Loads | Ensuring that the load is balanced and rigged correctly to prevent accidents during lifting operations. |

| Effective Communication | Using hand signals or other forms of communication to coordinate with team members during a lift. |

| Inspection of Equipment | Thoroughly inspecting lifting gear for any signs of damage or wear that could compromise safety. |

By honing these practical skills and techniques, you will be equipped to successfully navigate the practical components of the certification process, ensuring both safety and efficiency in your operations.

Time Management During the Rigger Exam

Managing time effectively during a certification assessment is crucial to ensure that all tasks are completed within the allotted time. Many candidates struggle with time constraints, often rushing through tasks or failing to allocate enough time to critical areas. A well-structured approach to time management can significantly improve your performance and reduce stress. Understanding how to balance speed with accuracy is essential to succeed in both the theoretical and practical parts of the evaluation.

Prioritize Key Tasks

One of the most important aspects of managing your time is recognizing which tasks are most time-sensitive or critical. These tasks should be prioritized so that they are given the attention they deserve. Here are some tips for prioritization:

- Read instructions carefully: Ensure that you understand the requirements before starting each section of the assessment.

- Focus on critical calculations: Take the necessary time to double-check measurements and calculations to prevent costly errors.

- Don’t rush the practical tasks: Proper setup and safety checks are vital and should not be overlooked in the interest of time.

Time Allocation Strategies

Once you have prioritized the critical areas, it’s important to allocate your time effectively. Below are some strategies to help you manage your time during the assessment:

- Set realistic time goals: Break down the tasks into smaller components and assign time limits to each part based on their difficulty and importance.

- Use a stopwatch or timer: If possible, track your time during the assessment to ensure that you are on schedule and avoid spending too much time on a single task.

- Allow time for review: Make sure to leave a few minutes at the end to review your work for errors or missed details.

By developing effective time management skills and staying focused throughout the assessment, you’ll ensure that you complete all tasks efficiently and accurately, boosting your chances of success.

How to Deal with Rigging Failures

Understanding how to respond to failures during a lifting or load-handling operation is essential for ensuring safety and minimizing damage. When a setup fails, it’s important to remain calm and systematically analyze the situation to prevent further complications. Identifying the root cause, whether it’s due to equipment, technique, or environmental factors, allows for corrective actions to be implemented quickly. The key to handling failures effectively lies in preparation, training, and learning from each experience.

Steps to Take After a Failure

When things go wrong during a task, it’s critical to take immediate action to secure the area and prevent further damage or injury. The following steps can help guide you through the process:

- Stop the operation immediately: As soon as a failure is detected, halt all activities to ensure no one is injured and that the situation does not worsen.

- Assess the situation: Look for the immediate cause of the failure, such as broken gear, improper load distribution, or environmental factors like wind.

- Secure the area: Clear the area of personnel and other potential hazards to prevent further risks.

- Notify supervisors: Inform your team leader or supervisor so they can assist with the resolution and help ensure proper reporting.

Common Causes of Rigging Failures

Failures can occur for a variety of reasons, and identifying these causes is essential for improving your performance and preventing future incidents. Some of the most common reasons include:

| Cause | Explanation |

|---|---|

| Incorrect Equipment Selection | Using the wrong gear for the weight or type of load can lead to failure. Always verify load ratings and specifications. |

| Poor Load Distribution | Improperly distributed weight can cause instability and imbalance, leading to equipment malfunction or tipping. |

| Human Error | Inadequate training, failure to follow procedures, or rushed actions can cause rigging mistakes that lead to failure. |

| Environmental Factors | Wind, weather, or ground conditions can contribute to unexpected problems during operations, especially with suspended loads. |

By understanding the common causes of failures and how to address them promptly, you can minimize the impact of an incident and improve your overall rigging performance. Proper training and experience will further help you react appropriately in difficult situations, reducing the likelihood of future errors.

After the Exam: Next Steps for Riggers

Once you have completed the assessment process, it’s important to know what steps to take next to continue advancing in your profession. The journey doesn’t end with simply passing the test; there are several actions to consider in order to maintain and improve your skills. This phase is critical for reinforcing the knowledge gained and applying it effectively in real-world situations.

Steps to Take After Completing the Assessment

Upon finishing the evaluation, here are some essential actions to follow:

- Review your results: Take time to carefully review the feedback you received to understand any areas of improvement. This will help guide your future learning efforts.

- Complete necessary documentation: Ensure that all certification paperwork is completed accurately and submitted in accordance with the required guidelines.

- Plan for ongoing training: Continuous professional development is essential. Consider attending workshops, training courses, or other programs to enhance your skills and stay updated on industry standards.

- Update your qualifications: Keep your credentials up to date, as certifications often require renewal or additional training after a certain period.

Building on Your Experience

Having completed the evaluation, you are now better equipped to take on more complex tasks. To build on your success, consider the following steps:

- Gain hands-on experience: Practical, on-the-job experience is invaluable for reinforcing theoretical knowledge. Seek opportunities to work on different types of projects to diversify your skills.

- Seek mentorship: Learn from experienced professionals in your field. Their insights can help you navigate challenges and advance your expertise more effectively.

- Stay informed: The rigging industry evolves over time, so staying informed about new tools, techniques, and safety practices is key to ongoing success.

Taking these steps after completing the assessment will help you continue to grow in your profession and ensure that you are fully prepared for the demands of the job. Developing a strong foundation now sets the stage for a long and successful career.

Benefits of Passing the Competent Rigger Exam

Successfully completing the assessment and earning certification brings a host of advantages that extend well beyond the immediate achievement. For those in the field of load handling and lifting operations, the process not only affirms one’s skills and knowledge but also enhances career opportunities and ensures safer practices in the workplace. Gaining recognition for your expertise opens doors to both professional growth and personal satisfaction.

Career Advancement Opportunities

Passing the assessment can significantly improve your career prospects by positioning you as a highly qualified professional. Some of the key career-related benefits include:

- Increased job opportunities: With the certification, you become eligible for more specialized roles, which can lead to higher-paying positions and greater job stability.

- Better job security: Certification helps you stand out in a competitive job market, increasing your chances of securing long-term employment.

- Professional growth: Certification showcases your commitment to continuous learning and advancement in your career, allowing you to take on more challenging projects and responsibilities.

Enhanced Safety and Efficiency

Another significant benefit of completing the assessment is the focus on safety and efficiency, which are critical in load handling tasks. Certified professionals are expected to adhere to higher standards, leading to:

- Improved safety practices: Knowledge of best practices for rigging and load management reduces the risk of accidents and injuries, ensuring a safer work environment for everyone involved.

- Increased operational efficiency: Proper training and certification lead to smoother, more effective operations, as certified professionals are better equipped to manage complex tasks and handle equipment correctly.

Ultimately, passing this assessment equips you with the necessary tools to excel in your role, offering a wide range of advantages for both personal development and workplace safety. It also allows you to demonstrate to employers, clients, and peers that you are capable of performing critical tasks with confidence and skill.