Ensuring a safe and sustainable workplace is a key aspect of modern industry, particularly in sectors where the handling of hazardous materials is common. Technicians and specialists are often tasked with maintaining high standards of safety and environmental protection. Understanding the correct practices and procedures is essential not only for compliance but also for promoting long-term ecological health.

Knowledge of safety protocols plays a crucial role in reducing risks and ensuring that harmful substances are properly managed. From minimizing waste to adhering to disposal regulations, professionals are expected to stay informed and apply their knowledge effectively in daily tasks. This guide provides a comprehensive overview of the necessary competencies and insights for success in the field.

Preparation is essential for those wishing to prove their expertise and readiness for handling critical tasks. The information contained here will help individuals prepare thoroughly by focusing on key areas of environmental responsibility, ensuring a thorough understanding of necessary practices. This approach will lead to more effective and compliant operations in any related field.

Key Concepts in Pollution Prevention

Understanding core principles of environmental responsibility is essential for those working in industries that handle potentially harmful materials. Implementing sustainable practices involves reducing negative impacts on natural resources through conscious decisions in every aspect of work. Professionals must be equipped with the knowledge to make these choices, focusing on minimizing waste and using resources efficiently.

One important concept is the reduction of hazardous materials at the source. By adopting strategies that limit the creation of waste or harmful substances, businesses can prevent contamination before it occurs. Furthermore, proper disposal methods ensure that any leftover materials do not harm ecosystems or human health.

| Concept | Description |

|---|---|

| Source Reduction | Minimizing the creation of waste or hazardous substances before they are produced. |

| Waste Management | Proper disposal and recycling methods to prevent harmful effects on the environment. |

| Resource Efficiency | Maximizing the use of materials and energy to reduce unnecessary consumption. |

| Sustainable Practices | Integrating methods that protect the environment while maintaining operational efficiency. |

Applying these principles not only reduces the ecological footprint but also helps in maintaining compliance with industry standards. Understanding these concepts and putting them into practice ensures that individuals contribute to a cleaner and healthier environment in their professional roles.

Understanding the S P2 Program

The S P2 program is designed to support professionals in various industries by promoting responsible practices that reduce harmful environmental impacts. It aims to provide individuals with the tools and knowledge necessary to comply with safety and environmental regulations. By participating in this initiative, workers gain the ability to identify risks and take proactive measures to minimize any negative effects on surrounding ecosystems.

Key Components of the Program

The program consists of various modules and resources that focus on different aspects of environmental stewardship. These components are structured to provide a comprehensive understanding of safe practices and procedures. Key areas covered in the program include:

- Safe handling and disposal of hazardous materials

- Reducing resource consumption through efficient use

- Adopting waste reduction techniques

- Complying with local, state, and federal regulations

Benefits of Participation

Engaging with the S P2 program offers several advantages to professionals and businesses alike. Some of the most significant benefits include:

- Improved compliance with environmental regulations

- Reduced risk of accidents and costly fines

- Enhanced sustainability efforts within the workplace

- Increased awareness of best practices for environmental safety

By integrating these principles into daily routines, participants help create safer work environments while contributing to broader efforts aimed at reducing ecological harm.

Role of Technicians in Environmental Control

Technicians play a crucial part in maintaining safe and sustainable practices within their workplaces. Their responsibilities go beyond technical skills; they must be well-versed in methods that reduce harmful impacts on the environment. By applying their knowledge of materials, systems, and regulations, technicians help minimize risks associated with waste, hazardous substances, and resource consumption.

Knowledge of environmental regulations is essential for technicians to ensure compliance with local and federal laws. They are often the first line of defense in identifying potential hazards and implementing corrective measures. Their role extends to properly managing resources, ensuring that materials are used efficiently and disposed of correctly.

Technicians are also responsible for educating others about safe practices. They may offer guidance on proper waste disposal, efficient energy use, and how to handle harmful substances safely. By fostering a culture of environmental responsibility, they contribute to long-term sustainability goals while ensuring the health and safety of their work environments.

Essential Skills for Exam Success

To succeed in any certification or knowledge-based assessment, individuals must develop a set of core competencies that ensure both understanding and practical application. These skills go beyond rote memorization and focus on critical thinking, problem-solving, and the ability to apply learned concepts in real-world scenarios. Mastering these skills can make the difference between passing and excelling in any challenging evaluation process.

Key Areas to Focus On

Developing proficiency in the following areas will enhance your readiness for any test or evaluation:

| Skill | Description |

|---|---|

| Conceptual Understanding | Grasping the core principles and applying them effectively in different situations. |

| Critical Thinking | Analyzing and evaluating information to make informed decisions and solve problems. |

| Time Management | Efficiently allocating time to study, review, and complete tasks under pressure. |

| Practical Application | Applying theoretical knowledge in practical settings to test real-world comprehension. |

Effective Study Techniques

Implementing proven study methods will also significantly increase the chances of success. Techniques such as active recall, spaced repetition, and focused practice on challenging topics allow for better retention and mastery of complex material. By engaging with the material regularly and in various forms, individuals are more likely to retain essential information when needed.

Common Environmental Hazards in Automotive Service

In any facility where mechanical systems are handled, various risks can pose significant environmental threats. These hazards can arise from the use of chemicals, improper disposal methods, or the handling of potentially harmful materials. Understanding these dangers is crucial for minimizing harm to both the environment and human health.

Some of the most common environmental risks in this industry include:

- Hazardous Chemicals: Many fluids and substances used in repairs, such as oils, solvents, and paints, can be harmful if not handled or disposed of correctly.

- Waste Management: Improper disposal of materials such as batteries, filters, or metal parts can lead to contamination of soil and water.

- Air Quality: Emissions from exhaust systems, paints, and other chemicals can pollute the air if adequate ventilation is not in place.

- Water Pollution: Leaking fluids or runoff from washing vehicles can contaminate local water sources.

- Noise Pollution: Excessive noise from tools and machinery can contribute to noise-related health issues if not controlled.

Recognizing these hazards is the first step in mitigating their impact. By implementing proper protocols and safety measures, it is possible to reduce environmental risks and maintain a safer workplace for everyone involved.

Strategies for Waste Reduction in Auto Shops

Effective waste reduction strategies are essential in any workshop environment, particularly when dealing with materials and resources that can have significant environmental impacts. By adopting a proactive approach, shops can minimize waste, improve efficiency, and contribute to a more sustainable industry. The following strategies offer practical ways to reduce excess materials and waste, benefiting both the business and the environment.

Implementing Efficient Resource Use

Reducing waste starts with using resources more efficiently. Here are several approaches that can help minimize material usage:

- Inventory Management: Regularly monitor and manage inventory to avoid overordering and ensure materials are used before they expire.

- Reuse and Recycle: Encourage the reuse of materials when possible, and set up systems for recycling items like metal parts, paper, and plastic.

- Correct Sizing: Ensure that materials are cut or measured correctly to avoid excess waste during processes.

Proper Disposal and Treatment of Waste

For waste that cannot be avoided, proper disposal and treatment methods are crucial. These practices can significantly reduce the negative impact on the environment:

- Segregate Waste: Separate hazardous waste from non-hazardous materials to ensure safe disposal and recycling.

- Compliant Disposal: Follow local regulations for the disposal of chemicals, oils, and other hazardous materials to prevent contamination.

- Waste Tracking: Implement a system to track waste generation, helping identify areas where reduction efforts can be further improved.

By integrating these strategies, workshops can achieve significant reductions in waste, reduce operational costs, and play a role in protecting the environment.

How to Manage Hazardous Materials Safely

Handling dangerous substances requires a thorough understanding of safety protocols to prevent harm to both individuals and the environment. Whether it’s chemicals, oils, or other harmful materials, proper management is essential to mitigate risks. Implementing the right procedures can help ensure that these substances are stored, used, and disposed of safely and responsibly.

Proper Storage and Labeling

Effective storage and accurate labeling are key to preventing accidents and exposure. Consider the following steps for managing hazardous materials:

- Labeling: Always ensure that containers are clearly labeled with the correct hazard symbols and handling instructions.

- Storage Conditions: Store hazardous materials in designated areas that meet safety regulations, away from heat, moisture, or other incompatible substances.

- Secure Containers: Use containers that are resistant to leaks or spills, and always seal them tightly when not in use.

Safe Handling and Disposal

Safe handling procedures reduce the risk of exposure or accidents while using hazardous materials. Additionally, proper disposal is essential for preventing contamination and legal issues:

- Personal Protective Equipment (PPE): Always wear the appropriate PPE, such as gloves, goggles, and aprons, to protect yourself from exposure.

- Use with Caution: Handle hazardous substances in well-ventilated areas and follow all safety guidelines during their use.

- Disposal Methods: Dispose of materials according to local regulations, ensuring that harmful substances do not end up in landfills or water systems.

By adhering to these guidelines, the risks associated with hazardous materials can be minimized, creating a safer working environment and ensuring environmental protection.

Best Practices for Water Conservation

Water is one of the most valuable resources, and using it efficiently is essential for sustainability. Reducing water consumption not only helps lower costs but also contributes to protecting the environment. By adopting best practices, businesses can play a significant role in conserving water while maintaining effective operations.

Effective Water Use Management

Implementing strategies to reduce water usage starts with managing how it is used in everyday tasks. Consider the following practices to minimize consumption:

- Regular Maintenance: Ensure all equipment and plumbing are in good condition to prevent leaks, which can waste a significant amount of water.

- Low-Flow Fixtures: Install low-flow faucets, showerheads, and toilets to reduce water usage without sacrificing performance.

- Water-Efficient Equipment: Use water-efficient machinery that minimizes water waste while performing necessary tasks.

Water Recycling and Reuse

Recycling and reusing water within your operations can greatly reduce overall consumption. Here are some effective ways to implement water reuse:

- Greywater Systems: Recycle water from sinks or washing machines for non-potable uses such as landscaping or cleaning.

- Rainwater Harvesting: Collect rainwater for use in irrigation or cleaning tasks, reducing the need for tap water.

- Closed-Loop Systems: Use closed-loop water systems in processes to reuse water without it being discharged into drains.

By adopting these practices, businesses can significantly reduce their water footprint, lower operational costs, and contribute to global water conservation efforts.

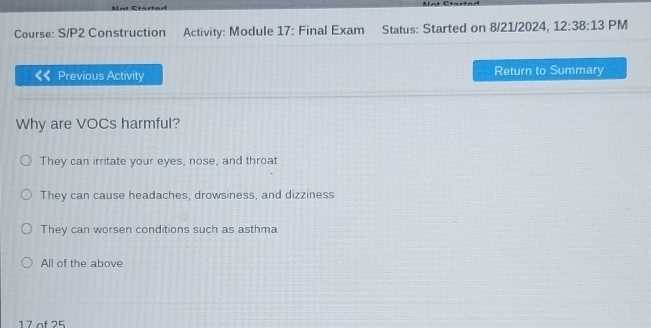

Air Quality Standards in Automotive Services

Maintaining a safe and clean indoor environment is essential, particularly in workspaces where harmful gases, fumes, and particulates may be generated. Adhering to air quality standards is not only important for the health of workers but also for compliance with regulations. Proper ventilation, monitoring, and the use of effective control measures can significantly improve air quality within such environments.

Key standards and guidelines help to ensure that the air remains free of harmful contaminants. These measures include managing emissions, providing adequate ventilation, and using appropriate equipment to filter harmful particles and gases from the air.

| Contaminant | Standard Limit | Recommended Control Measure |

|---|---|---|

| Carbon Monoxide (CO) | 50 ppm (parts per million) | Ensure proper ventilation and exhaust systems are in place. |

| Volatile Organic Compounds (VOCs) | 500 µg/m³ | Use low-VOC products and maintain an effective air filtration system. |

| Particulate Matter (PM) | 25 µg/m³ (PM2.5) | Install air purifiers and regularly clean work areas. |

| Nitrogen Dioxide (NO2) | 100 ppb (parts per billion) | Monitor emissions and improve air circulation. |

By adhering to these standards and ensuring that control measures are in place, businesses can create a safer and healthier environment for their workers and customers. Regular air quality assessments and adjustments to systems can also help maintain compliance and improve overall air conditions.

Energy Efficiency in Auto Repair Shops

Improving energy efficiency in repair shops is crucial for reducing operational costs and contributing to environmental sustainability. By adopting energy-saving practices, businesses can lower their energy consumption, cut costs, and improve overall efficiency. Simple upgrades and mindful practices can make a big difference in how energy is used throughout the workspace.

Key Areas for Energy Efficiency

There are several areas in a repair shop where energy efficiency can be improved. By focusing on these aspects, businesses can achieve meaningful reductions in energy consumption:

- Lighting Upgrades: Replacing traditional incandescent bulbs with energy-efficient LED lighting can drastically reduce electricity usage and lower energy bills.

- Efficient Equipment Use: Regular maintenance of equipment ensures that machines run at peak efficiency, reducing the amount of energy wasted during operation.

- Optimized Heating and Cooling: Proper insulation, programmable thermostats, and energy-efficient HVAC systems help regulate temperature without unnecessary energy waste.

Practical Tips for Improving Efficiency

Beyond upgrades, there are everyday actions and habits that can help optimize energy use:

- Shut Off Unused Equipment: Encouraging employees to power down equipment and tools when not in use reduces standby energy consumption.

- Smart Power Management: Installing timers or motion sensors for lighting and tools helps ensure energy is only used when necessary.

- Employee Training: Teaching staff about the importance of energy conservation and how small changes can lead to large savings can promote a culture of efficiency.

By incorporating these practices, repair shops can not only reduce costs but also contribute to environmental conservation, making the workplace more sustainable and cost-effective in the long term.

Disposal Guidelines for Automotive Waste

Proper disposal of waste materials is essential for maintaining a safe and sustainable environment in any workshop. By following clear and responsible disposal practices, businesses can reduce their impact on the environment and comply with regulatory requirements. This section outlines essential guidelines for managing various types of waste that may arise during routine repairs and maintenance activities.

Different types of waste require specific disposal methods to ensure they are handled safely and efficiently. The goal is to prevent contamination of natural resources and ensure that materials are disposed of in a way that minimizes harm to both the environment and human health.

- Used Oils and Fluids: Engine oils, transmission fluids, and coolant liquids must be collected and disposed of at licensed recycling facilities. Never pour them down drains or throw them in the trash.

- Batteries: Vehicle batteries contain hazardous chemicals and must be taken to a certified recycling center. Many parts suppliers and repair shops accept used batteries for proper disposal.

- Tires: Old tires should be sent to facilities that specialize in recycling or reusing them. Many tire retailers offer tire disposal services for a small fee.

- Paint and Solvents: Paints, thinners, and other solvent-based materials should be stored properly and disposed of through local hazardous waste programs to avoid contamination of groundwater.

In addition to these specific materials, it is important to adhere to local environmental regulations regarding the disposal of general waste. Proper labeling, storage, and handling of waste materials reduce the risks of contamination and improve the overall safety of the workplace.

By following these disposal guidelines, shops not only comply with legal obligations but also contribute to a more sustainable operation and a cleaner environment.

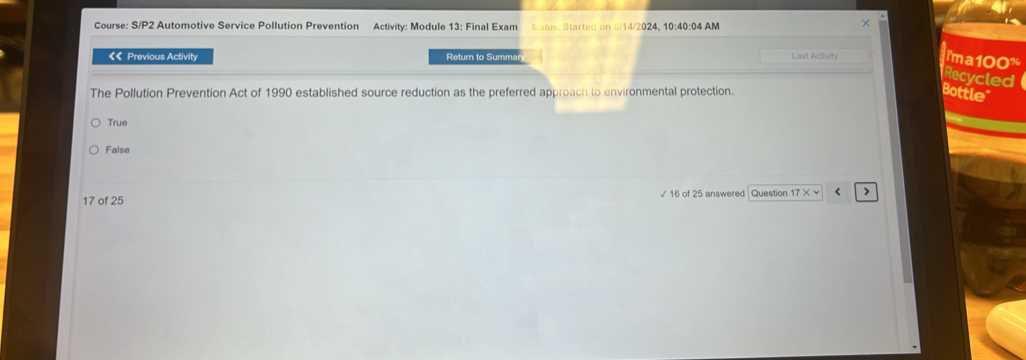

Regulations for Automotive Pollution Prevention

Regulatory standards play a critical role in ensuring that businesses operate responsibly, reducing the environmental impact of their activities. In industries where hazardous materials and emissions are common, adherence to legal requirements helps protect public health and the surrounding ecosystem. This section covers key regulations designed to manage waste, emissions, and chemical use in repair shops and similar facilities.

Environmental Protection Laws

Various environmental protection laws establish clear guidelines for businesses, ensuring they manage resources efficiently and reduce harmful effects. These regulations aim to limit the release of toxic substances into the air, water, and soil. Some of the most important guidelines include:

- Clean Air Act (CAA): This federal law regulates air emissions from stationary and mobile sources. Shops must adhere to local air quality standards and limit emissions from operations like engine diagnostics and repairs.

- Resource Conservation and Recovery Act (RCRA): This act governs the disposal of hazardous waste. It sets strict requirements for the management of waste products such as chemicals, oils, and batteries.

- Clean Water Act (CWA): The CWA regulates discharges of pollutants into water bodies, setting standards for wastewater treatment and the safe disposal of fluids such as coolant and oils.

Local and State Regulations

In addition to federal laws, many local and state governments have specific regulations that further limit emissions, waste disposal, and the use of chemicals in repair shops. These regulations may vary, so it is essential for businesses to stay informed about local requirements to avoid fines or penalties.

- State-Specific Waste Management Laws: States may have stricter requirements for the storage, disposal, and recycling of hazardous materials, particularly in areas with high population densities or vulnerable ecosystems.

- Local Zoning and Air Quality Rules: Municipalities often implement their own air quality standards and zoning laws to minimize the environmental footprint of nearby businesses.

By staying up-to-date with these regulations and actively working to comply, businesses not only avoid legal issues but also contribute to environmental sustainability and public health.

Handling Chemical Spills in Automotive Workplaces

In workplaces where hazardous substances are regularly used, it’s essential to have proper protocols in place to address spills quickly and efficiently. Chemical leaks or spills can pose serious risks to both the environment and human health, making swift containment and cleanup critical. This section outlines the necessary steps for managing such incidents to minimize damage and ensure safety.

The first step in handling a chemical spill is to remain calm and follow established procedures. Immediate action can prevent the spread of hazardous materials and reduce exposure to toxic fumes or harmful substances. Whether the spill involves fluids like oils, fuels, or cleaning agents, effective containment is key to managing the situation safely.

Steps to Take When a Spill Occurs

- Alert the Personnel: As soon as a spill is noticed, notify all staff members in the area. Clear the area and restrict access to prevent unnecessary exposure or further contamination.

- Assess the Situation: Evaluate the size of the spill, the type of chemical involved, and any potential risks such as flammability or toxicity. Understanding the nature of the substance will help determine the best course of action for cleanup.

- Use Appropriate Spill Kits: Have spill response kits readily available, including absorbent materials, neutralizing agents, gloves, and eye protection. These kits should be suited to the chemicals typically found in the workplace.

- Contain the Spill: Prevent the chemical from spreading by using barriers such as absorbent pads or sand. If possible, use booms or barriers to limit the flow of liquids and contain the spill within a designated area.

Cleaning and Disposal

Once the spill is contained, the cleanup process can begin. Ensure that all affected areas are thoroughly cleaned using appropriate methods and materials. After cleaning, safely dispose of the contaminated materials in accordance with local regulations, ensuring that waste is properly labeled and handled.

- Neutralize Harmful Chemicals: If applicable, use neutralizing agents to make the chemical spill less harmful. Always follow the manufacturer’s instructions and ensure compatibility with the spilled substance.

- Proper Disposal: Ensure that the contaminated materials, including cleanup materials, are disposed of through licensed waste disposal services. Never dispose of hazardous waste in regular trash bins or down drains.

Proper training and preparation are crucial for handling spills effectively. All personnel should be familiar with safety procedures and know the location of necessary cleanup equipment. Regular drills and updates on spill response protocols help maintain a safe working environment and reduce the risks associated with hazardous chemical spills.

Testing Your Knowledge of Pollution Control

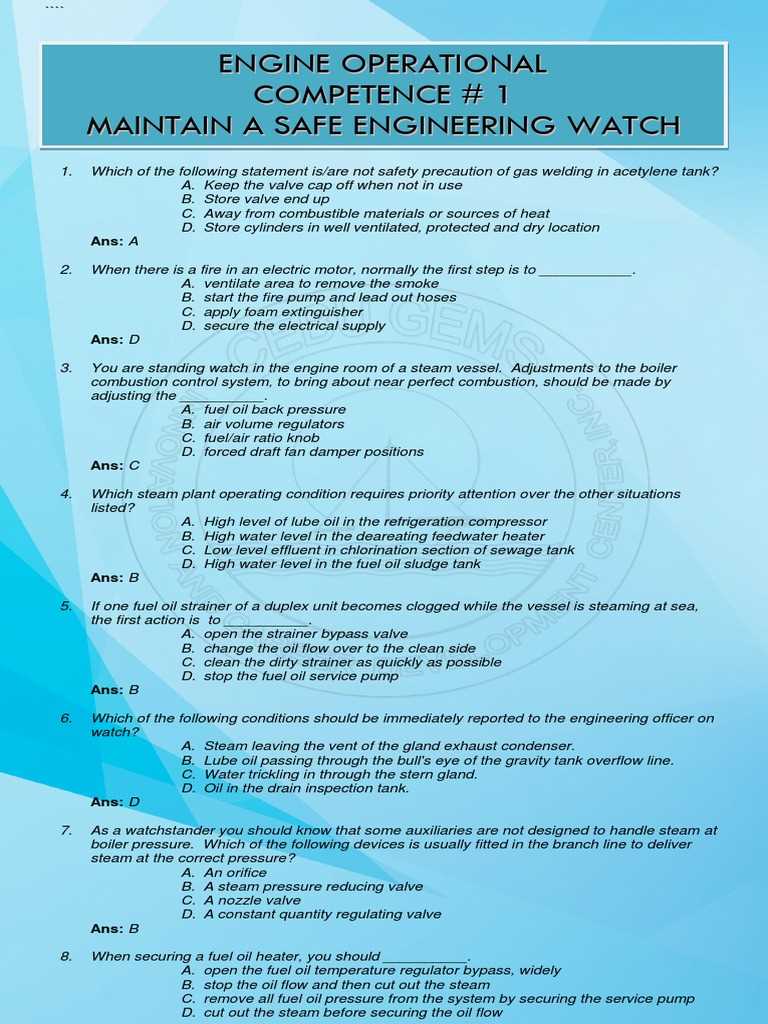

Assessing your understanding of key environmental safety concepts is essential for ensuring a safe and sustainable working environment. By testing your knowledge, you can identify areas where further learning is needed and reinforce best practices for handling hazardous materials and reducing environmental impact. This section aims to guide you through the process of evaluating your awareness of crucial safety protocols and regulations.

Regularly assessing your knowledge allows you to stay current with industry standards and improve your ability to handle challenging situations. The following activities and questions help reinforce your understanding of effective strategies and regulations for minimizing environmental risks in the workplace.

Self-Assessment Questions

- What are the most common types of hazardous materials in your workplace?

- How would you respond if you discovered a hazardous spill?

- What steps should be taken to ensure proper waste disposal?

- Can you identify the proper safety equipment needed for chemical handling?

- How can energy consumption be reduced without compromising work efficiency?

Practical Scenarios for Testing

- Scenario 1: A worker spills a liquid in a confined area, and the substance is unknown. What immediate actions should be taken to minimize the risk of exposure?

- Scenario 2: During routine cleaning, you notice equipment that has become inefficient and is consuming more energy than necessary. What steps should be taken to improve energy efficiency?

- Scenario 3: You are tasked with organizing a waste management protocol for the workplace. What types of waste require special handling, and how should they be categorized?

Through consistent self-assessment, employees can strengthen their understanding of environmental responsibility and contribute to maintaining a safe, eco-friendly work environment. These exercises not only test your theoretical knowledge but also provide practical solutions for real-world challenges. By mastering these concepts, you will be better prepared to handle complex situations and ensure compliance with environmental standards.

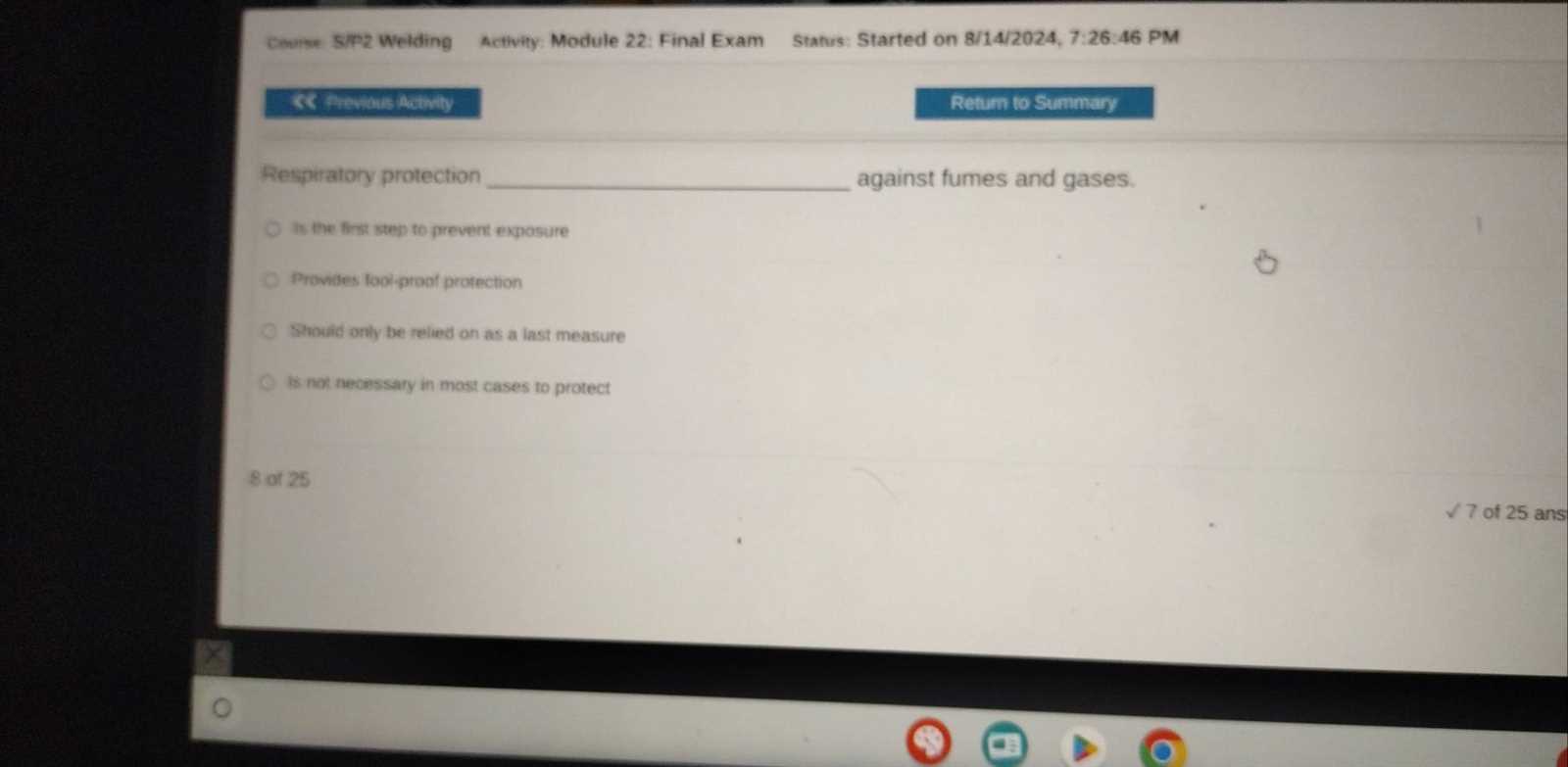

Preparing for the S P2 Assessment

Preparation for an assessment in this field involves gaining a deep understanding of the principles and practices that ensure safety, environmental responsibility, and regulatory compliance. It is crucial to be familiar with key concepts, strategies, and industry standards that guide workplace procedures and decision-making. The goal is not just to memorize information but to be able to apply that knowledge effectively in various scenarios.

To excel in the assessment, you should focus on developing a comprehensive grasp of safety protocols, material handling procedures, energy efficiency strategies, and environmental impact reduction techniques. By reviewing practical case studies, common risks, and solutions to everyday challenges, you can better prepare for the types of questions and situations that may arise. Below are some tips and strategies to help you prepare efficiently.

Effective Study Strategies

- Understand Key Concepts: Focus on the core principles, such as handling hazardous materials, waste management, and energy conservation. Make sure you have a clear understanding of these fundamental areas.

- Review Relevant Regulations: Familiarize yourself with the legal standards and guidelines related to workplace safety and environmental management. Knowing the rules ensures that you can apply them appropriately when needed.

- Practice with Real-Life Scenarios: Review practical examples or hypothetical situations. Understanding how to react in specific cases will help reinforce theoretical knowledge.

- Use Study Materials: Take advantage of available resources, such as study guides, flashcards, and practice quizzes. These can help consolidate your knowledge and identify any areas that need more attention.

Key Areas to Focus On

- Risk Management: Understand how to identify, assess, and manage risks in a workplace setting.

- Emergency Response Procedures: Be prepared to respond appropriately in case of chemical spills, fires, or other hazardous situations.

- Environmental Impact Reduction: Familiarize yourself with strategies to minimize waste, conserve resources, and reduce the overall environmental footprint of the workplace.

- Safety Equipment and Tools: Know the types of equipment necessary to maintain a safe environment, and how to use them effectively.

By following these preparation strategies, you will build a solid foundation of knowledge and skills that are crucial for passing the assessment with confidence. Successful preparation involves not only reviewing materials but also engaging with the content and practicing how to apply what you’ve learned in real-world situations.

Tips for Retaining Key Information

Retaining important information is essential for success in any field, especially when dealing with complex material. Effective memory techniques help ensure that critical concepts and details are easily recalled when needed. It is important to focus on both understanding and remembering key topics, as this combination enhances long-term retention and practical application. Below are several strategies to help improve your ability to remember vital information and apply it confidently.

Effective Memory Techniques

- Chunking Information: Break down large amounts of information into smaller, more manageable parts. This makes it easier to focus on one section at a time and retain the material in pieces.

- Active Recall: Regularly test yourself on the material rather than just reviewing notes. This active engagement strengthens memory and helps identify areas that need further review.

- Visual Aids: Use diagrams, charts, and mind maps to visualize complex concepts. Associating visual representations with key points can make it easier to remember and understand the material.

- Storytelling or Mnemonics: Create a story or mnemonic that links new information to something familiar. This technique helps connect abstract concepts to known experiences or patterns.

Study Habits for Better Retention

- Consistent Review: Regularly revisit your notes and study materials. Spaced repetition, where you review material at increasing intervals, is one of the most effective ways to keep information fresh in your mind.

- Teach Others: Explaining the material to someone else forces you to understand it fully and reinforces your knowledge.

- Stay Organized: Keep your study materials well-organized. This reduces the time spent looking for information and helps maintain focus on the most important points.

- Healthy Lifestyle: Ensure you are getting enough sleep, exercise, and nutrition. A well-rested and healthy mind retains information more efficiently.

By incorporating these strategies into your routine, you will be better equipped to retain key information and confidently apply it in real-life situations. Memory retention is a skill that improves with consistent practice and effective techniques, ensuring long-term success in mastering important concepts.

Post-Exam Resources for Further Learning

After completing any assessment, the learning journey doesn’t stop. It’s important to continue building upon the knowledge gained by utilizing additional resources that can deepen understanding and enhance skills. There are various tools available that provide supplementary information, practical applications, and opportunities for further exploration. Below are some effective resources that can help extend your learning and reinforce key concepts.

Online Courses and Webinars

- Interactive Courses: Platforms like Coursera, Udemy, and LinkedIn Learning offer specialized courses that dive deeper into specific topics. These courses are often led by experts and provide hands-on learning experiences.

- Webinars and Virtual Workshops: Attend live sessions or watch recorded webinars on platforms such as YouTube or industry-specific websites. These sessions often cover advanced topics and provide the latest industry trends.

- MOOCs (Massive Open Online Courses): Universities and institutions around the world offer free or low-cost online courses that are accessible to anyone interested in further study. These courses often provide certifications upon completion, adding value to your learning.

Books and Journals

- Specialized Textbooks: Books written by industry leaders can help you explore advanced topics in detail. They often include case studies, real-world applications, and research findings.

- Scholarly Journals: Subscribe to journals related to your field of interest. These publications often feature in-depth research articles, reviews, and emerging trends that provide fresh perspectives.

- Industry Reports: Many industry organizations and research firms publish reports that provide valuable insights and data. These can help you stay informed on the latest developments and best practices.

By utilizing these resources, you can continue to expand your knowledge, refine your skills, and stay current with the latest trends in the field. Lifelong learning is key to success and these tools will guide you in applying your knowledge in practical, real-world settings.

Staying Updated with Environmental Regulations

In industries that handle hazardous materials and potentially harmful substances, it is crucial to stay informed about the evolving rules and guidelines set by governing bodies. Regulatory requirements are constantly changing to address new environmental concerns, technological advancements, and scientific discoveries. Keeping up with these updates not only ensures compliance but also promotes responsible practices that contribute to a safer and cleaner environment.

Key Resources for Monitoring Regulatory Changes

- Government Websites: Regularly check official websites such as the Environmental Protection Agency (EPA) or local regulatory bodies for the latest updates on environmental laws and standards.

- Industry Associations: Join professional groups that focus on environmental best practices. These organizations often send newsletters and updates regarding new regulations and their implications.

- Regulatory Databases: Use online regulatory platforms that compile and track legal changes. These databases allow you to search for specific regulations by category or keyword.

Strategies for Continuous Learning

- Attend Webinars and Conferences: Participate in industry-specific webinars and conferences where experts discuss changes in legislation and share insights into upcoming regulatory trends.

- Subscribe to Trade Publications: Many trade magazines and journals offer sections dedicated to regulatory changes, providing summaries and analyses of new laws and their impact on the industry.

- Professional Training: Enroll in ongoing educational courses that focus on environmental compliance. These courses often provide updated materials that reflect the latest regulatory changes.

By using these resources and actively seeking out the most current information, professionals can ensure their operations meet all legal requirements and continue to evolve with the changing regulatory landscape.