In many industries, understanding safety protocols for operating various machinery is crucial for maintaining a secure work environment. With proper knowledge and preparation, workers can ensure both their own safety and that of their colleagues. This section delves into the essential concepts and principles needed to pass certification related to equipment handling, focusing on key areas that reflect real-world situations.

Comprehensive preparation is necessary for anyone aiming to operate heavy machinery or equipment. The certification process is designed to evaluate your understanding of both theoretical concepts and practical applications. To pass successfully, one must be familiar with the regulations, safety measures, and the responsibilities associated with such operations.

Through this guide, we aim to provide the necessary tools and insights to help you succeed. Whether you’re studying independently or with a group, focusing on the core principles will ensure you are well-equipped to handle the challenges and demonstrate your competence in safety practices.

Safe Lift 2 Exam Answers

Successfully passing the assessment related to equipment handling requires a deep understanding of operational safety standards and regulations. The test evaluates knowledge in critical areas, ensuring that individuals are fully prepared for practical challenges on the job. The focus is on both theoretical principles and practical application, with an emphasis on risk prevention and proper procedures in machinery operation.

To excel, candidates must familiarize themselves with key topics covered in the assessment, including safety protocols, emergency procedures, and the proper use of protective equipment. A solid grasp of these elements will help reinforce confidence when facing complex scenarios and ensure that safety practices are followed consistently. Understanding the underlying principles will also improve retention, making it easier to navigate through the test with a clear approach.

Preparation for the certification is key to mastering the material. Focused study on the core concepts, along with hands-on practice where applicable, is essential for achieving success. By tackling sample questions and revisiting important topics, individuals can ensure they are fully equipped to demonstrate their readiness for safe and efficient operation in real-world environments.

What is Safe Lift 2 Exam?

This certification is designed to assess individuals’ knowledge and skills related to operating equipment in a safe and efficient manner. The test evaluates understanding of crucial safety practices, the proper handling of machinery, and adherence to industry standards. The primary goal is to ensure that candidates can operate equipment without posing risks to themselves or others in the workplace.

Participants are required to demonstrate their proficiency in key areas such as risk management, emergency response, and the correct use of safety gear. This assessment also includes evaluating theoretical knowledge along with the practical application of safety measures during real-world operations. Successful completion of the test is essential for those wishing to prove their readiness for handling complex machinery and ensuring safe work environments.

Key Topics Covered in Safe Lift 2

The assessment encompasses a range of essential topics related to safe operation and maintenance of heavy machinery. These subjects ensure that individuals are fully prepared to handle equipment in various environments while adhering to established safety guidelines. Each topic is designed to enhance both theoretical understanding and practical application, focusing on risk prevention and proper operational procedures.

| Topic | Description |

|---|---|

| Safety Protocols | Understanding essential procedures for ensuring a safe work environment while operating equipment. |

| Risk Management | Identifying and mitigating potential hazards associated with machinery operation. |

| Emergency Procedures | Responding effectively to accidents or equipment malfunctions to minimize harm and damage. |

| Protective Equipment | Proper use and maintenance of safety gear to protect operators during tasks. |

| Regulatory Compliance | Adhering to local and international standards for machinery operation and workplace safety. |

| Maintenance and Inspections | Routine checks and repairs to ensure equipment is in optimal condition and functioning safely. |

How to Prepare for the Exam

Preparing for the certification assessment requires a structured approach to mastering the material. Focused study and understanding the core principles are essential to perform well. By following a clear plan, you can ensure that you are well-prepared for both theoretical and practical aspects of the test.

- Review Study Materials – Collect reliable resources, including manuals, guides, and training materials related to equipment safety and operations.

- Understand Key Concepts – Focus on crucial topics like safety procedures, emergency response, and risk management. Knowing these principles will help you navigate questions effectively.

- Practice with Mock Tests – Take sample tests to familiarize yourself with the format and question types. This will help improve your time management and test-taking skills.

- Hands-On Practice – Whenever possible, engage in practical exercises to apply what you’ve learned. This reinforces your knowledge and prepares you for real-world situations.

- Group Study Sessions – Collaborating with others can provide valuable insights and a deeper understanding of complex topics.

By systematically following these steps, you can approach the assessment with confidence and increase your chances of success.

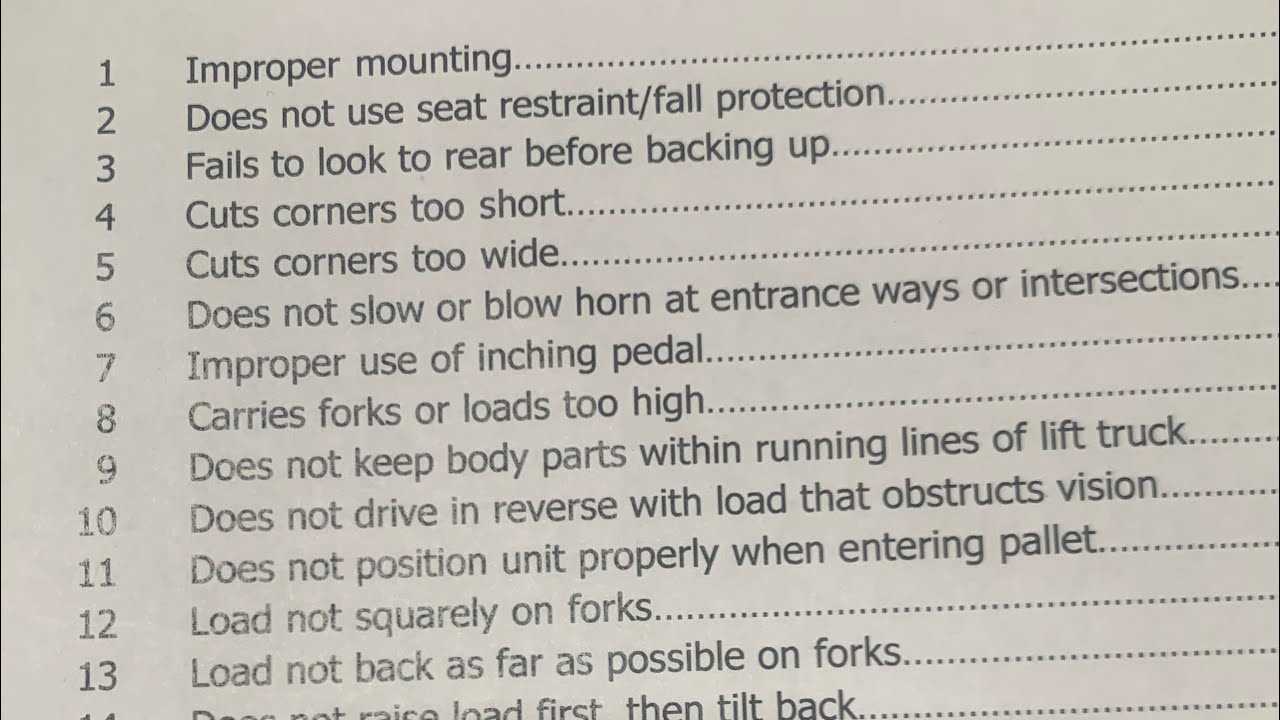

Common Mistakes to Avoid

When preparing for a certification related to equipment operation, it is crucial to recognize and avoid common errors that can hinder success. These mistakes often stem from misunderstanding key concepts, inadequate preparation, or failure to follow essential guidelines. By being aware of these pitfalls, candidates can approach the assessment with more confidence and accuracy.

- Neglecting Safety Procedures – Failing to focus on safety protocols can lead to confusion during the test and potentially poor performance. It is vital to understand and memorize all safety measures.

- Ignoring Practical Application – Focusing solely on theory without practicing real-world scenarios can result in difficulties when applying knowledge under pressure.

- Overlooking Details – Missing important details in instructions or questions can cause mistakes. Ensure careful reading of every section before answering.

- Not Reviewing Regulations – Regulations often form a large part of the assessment. Failing to stay up to date with local and international safety standards may result in incorrect responses.

- Relying Too Much on Memorization – While memorizing facts is important, understanding the underlying principles is equally crucial for long-term retention and real-life application.

By avoiding these common mistakes and adopting a comprehensive study approach, you can increase your chances of achieving a successful outcome.

Benefits of Safe Lift 2 Certification

Obtaining certification in equipment handling offers numerous advantages, both professionally and personally. By acquiring this credential, individuals not only demonstrate their expertise in operating machinery safely, but also enhance their career prospects in various industries. This qualification assures employers of an individual’s ability to adhere to best practices and effectively manage risk in the workplace.

Professional Advantages

Certified individuals are often considered more reliable and competent, which can lead to better job opportunities and career advancement. The certification showcases a commitment to safety and a thorough understanding of operational procedures, making it a valuable asset for anyone working in fields that require the use of heavy machinery or equipment.

Workplace Safety and Compliance

Certification also plays a critical role in ensuring workplace safety. It demonstrates a candidate’s proficiency in following safety protocols, reducing accidents, and maintaining compliance with industry regulations. Employers benefit from a safer work environment, fewer incidents, and reduced insurance costs.

| Benefit | Description |

|---|---|

| Enhanced Career Opportunities | Certified individuals are seen as more qualified and may be offered higher-paying positions and promotions. |

| Increased Safety Knowledge | By completing certification, individuals gain a deeper understanding of operational safety, which contributes to fewer accidents and a safer work environment. |

| Compliance with Industry Standards | Certification ensures adherence to local and international safety regulations, protecting both workers and employers from legal issues. |

| Confidence in Operations | With the certification, operators are more confident in their ability to handle machinery safely and efficiently, leading to better performance. |

Understanding Safety Regulations in Lift Operations

In any workplace where machinery is used, adhering to established safety standards is essential for protecting both workers and equipment. The regulations governing equipment operation provide clear guidelines on how to handle machinery safely, reduce risks, and ensure compliance with legal requirements. Understanding these regulations is crucial for maintaining a secure and efficient working environment.

- Operator Training – Operators must receive proper training to ensure they understand both the machinery’s functions and the safety protocols that apply to their operation.

- Risk Assessment – Conducting thorough risk assessments before operating equipment helps identify potential hazards and establish measures to mitigate those risks.

- Maintenance and Inspections – Regular checks and maintenance are vital to ensuring that machinery remains in safe working condition. Inspections should be done routinely, and any issues addressed promptly.

- Safety Gear – Operators should always wear appropriate personal protective equipment (PPE) such as helmets, gloves, and safety boots to prevent injuries.

- Compliance with Local and International Standards – It is important to follow both local and international safety regulations to avoid legal consequences and ensure the well-being of all workers involved.

By adhering to these safety regulations, organizations can minimize the likelihood of accidents and improve overall operational efficiency. Understanding these rules is not only a legal requirement but a necessary practice for fostering a culture of safety within the workplace.

Step-by-Step Guide to Passing Safe Lift 2

Successfully completing a certification related to equipment operation requires careful planning and systematic preparation. By following a clear and structured approach, candidates can ensure that they are ready for both the theoretical and practical components of the assessment. This guide breaks down the essential steps to help you pass with confidence and demonstrate proficiency in handling machinery safely and effectively.

1. Gather the Right Materials

The first step in your preparation is to collect all necessary study materials. This includes manuals, safety guidelines, training videos, and any available practice tests. Ensure that the materials you choose are up-to-date and relevant to the latest standards in machinery operation and safety.

2. Review Key Concepts

Understanding core concepts such as safety protocols, emergency procedures, and risk management is essential. Dedicate time to studying these topics, as they will form the foundation of your knowledge during the assessment. Be sure to review both theoretical knowledge and practical applications to cover all aspects of the certification.

Once you have your materials and concepts in place, follow these steps to stay organized:

- Create a Study Schedule – Plan your study sessions ahead of time, allocating specific periods to review different topics.

- Take Practice Tests – Practice tests simulate real exam conditions and will help you get familiar with the types of questions you will encounter.

- Engage in Hands-On Practice – Whenever possible, gain practical experience by operating machinery under supervised conditions to reinforce your theoretical knowledge.

- Participate in Study Groups – Joining a study group allows you to discuss challenging topics and learn from others’ experiences.

By following this guide, you will be better prepared to pass the certification, ensuring both your safety and the safety of those around you when operating heavy machinery.

Where to Find Reliable Study Materials

When preparing for a certification related to machinery operation, it’s important to use trusted and accurate resources. Reliable study materials are essential for building a solid understanding of both the theoretical and practical aspects of the assessment. In this section, we will explore some of the best places to find comprehensive and up-to-date study materials that will support your preparation efforts.

1. Official Training Providers

The best place to start is with official training providers or accredited organizations that offer courses and study guides specific to the certification. These resources are often designed by experts in the field and align with the standards required for the assessment. Many organizations also offer practice tests, video tutorials, and interactive learning modules.

2. Online Educational Platforms

Online platforms like Coursera, Udemy, and LinkedIn Learning offer a wide variety of courses related to equipment operation and safety protocols. These platforms provide flexible learning options, ranging from beginner to advanced levels. Look for courses with high ratings and reviews from past participants to ensure their quality and relevance.

Additionally, consider searching for resources such as:

- Books and Manuals – Many textbooks and manuals provide detailed information on safety procedures and equipment operation. Check online bookstores or libraries for relevant titles.

- Industry Forums and Websites – Many forums and online communities dedicated to machinery operation provide valuable insights and recommendations for study materials. Be sure to verify the accuracy of the information you find.

- Government and Regulatory Agencies – Local government websites and safety regulatory bodies often offer free resources and publications to help you stay informed about standards and best practices.

By utilizing these resources, you can ensure that your study materials are credible, up-to-date, and aligned with industry standards, helping you prepare effectively for your certification assessment.

Exam Format and Question Types

Understanding the structure of the assessment is key to effective preparation. The test is designed to evaluate your knowledge in both theoretical concepts and practical applications. By familiarizing yourself with the format and the types of questions, you can approach the assessment with greater confidence and focus.

The format typically consists of multiple-choice questions, scenario-based questions, and practical tasks. Each section is crafted to assess your understanding of safety protocols, operational procedures, and decision-making skills in real-world situations. Here’s a breakdown of what you can expect:

- Multiple-Choice Questions – These questions test your theoretical knowledge, requiring you to select the correct answer from a list of options. They may cover topics such as safety standards, machinery functions, and emergency procedures.

- Scenario-Based Questions – These questions present hypothetical situations where you must choose the most appropriate response. They assess your ability to apply safety principles and problem-solving skills in various work environments.

- Practical Tasks – In addition to written questions, you may be asked to demonstrate your skills in handling equipment, performing checks, or responding to safety incidents. This section evaluates your hands-on ability to perform tasks safely and efficiently.

Being familiar with these question types will help you prepare mentally and strategically. Remember, thorough preparation is key to mastering the content and performing confidently during the assessment. Review your materials, practice regularly, and focus on understanding both the theory and the practical aspects of the job.

How to Improve Your Knowledge Retention

Effective preparation goes beyond simply reviewing information. To truly master the content, it’s essential to adopt strategies that enhance memory retention. Improving how you absorb and recall information will ensure you can apply what you’ve learned during both theoretical assessments and practical tasks. Below are several techniques that can help strengthen your ability to retain and recall important material.

1. Use Active Recall Techniques

Active recall involves testing yourself on the material rather than just passively reading or reviewing notes. This method forces your brain to retrieve information, strengthening your memory. You can use flashcards, practice tests, or even try explaining concepts aloud to reinforce your understanding and retention. Regular self-quizzing is one of the most effective ways to enhance memory retention.

2. Space Your Learning Sessions

Spacing out your study sessions over a period of time–also known as spaced repetition–helps move information from short-term to long-term memory. Instead of cramming all at once, break your study time into smaller, more frequent intervals. Review the material at increasing intervals to reinforce your knowledge. This technique has been proven to improve retention and ensure that you remember key concepts over the long term.

Additional strategies to enhance memory retention include:

- Teach What You’ve Learned – Explaining concepts to others forces you to understand the material in a deeper way. Teaching helps clarify any gaps in your knowledge and reinforces your memory.

- Use Visual Aids – Incorporate diagrams, charts, and mind maps to visualize complex information. Visual aids can make abstract concepts more tangible and easier to remember.

- Take Regular Breaks – Studies show that taking breaks during study sessions improves focus and retention. Try using the Pomodoro technique, which involves studying for 25 minutes followed by a 5-minute break.

By applying these techniques consistently, you will be better prepared to retain critical information and perform at your best during the assessment process.

Time Management Tips for Safe Lift 2

Managing your time effectively during the preparation phase and the actual test is crucial for success. Whether you’re working through study materials or tackling tasks under pressure, adopting smart time management strategies will help ensure you stay organized and perform to the best of your ability. Below are key techniques to help you maximize your time and stay focused throughout the process.

1. Set Clear Goals and Prioritize

Start by setting clear, specific goals for each study session. Break down the material into manageable chunks and prioritize areas that need more attention. Focusing on high-priority topics first ensures that you cover the most critical content while leaving less demanding material for later. This approach helps reduce stress and increases productivity, allowing for better retention and a more effective study routine.

2. Use a Study Schedule

Creating and sticking to a study schedule is essential for efficient time management. Allocate specific times for studying, revising, and taking breaks. Incorporate short, focused study sessions with regular breaks to avoid burnout. The Pomodoro technique, which involves 25 minutes of focused study followed by a 5-minute break, is a proven method for maintaining concentration and maximizing efficiency.

Additional time management techniques to consider:

- Track Your Progress – Regularly assess your progress to stay on track. Use a checklist or planner to mark off completed tasks and highlight areas that need further attention.

- Avoid Multitasking – Focus on one task at a time to avoid distractions and improve the quality of your work. Multitasking can lead to errors and decrease overall efficiency.

- Prepare Ahead of Time – When possible, review materials in advance and come up with a plan for the day of the assessment. Having everything organized will minimize stress and allow you to manage your time more effectively.

By utilizing these time management strategies, you can optimize your preparation efforts and perform confidently, ensuring that you have enough time to complete every task accurately.

Real-Life Scenarios Covered in the Exam

Practical situations are often an essential part of the testing process, as they assess how well candidates can apply their knowledge in real-world contexts. These scenarios help ensure that you not only understand the theory behind the material but can also effectively manage situations that might arise in your daily work. Below are examples of real-life scenarios you may encounter in assessments, reflecting typical challenges professionals face in their fields.

1. Handling Equipment Malfunctions

One common scenario involves responding to equipment failures. In such cases, candidates must demonstrate their ability to troubleshoot and address technical issues promptly. This includes knowing how to assess the problem, determine the cause, and implement safe solutions. It’s crucial to understand the steps to take in emergencies to ensure the safety of both equipment and personnel.

2. Managing Emergency Situations

Another critical scenario focuses on emergency preparedness. You may be tested on how to react when an unexpected situation arises, such as a safety hazard, injury, or unexpected malfunction. This includes knowing the proper emergency protocols and understanding how to take control of the situation to minimize risks. Being familiar with safety protocols and communication procedures can help prevent further escalation.

Other real-world situations that may be covered include:

- Assessing Risk Levels – Evaluating environments and tasks to identify potential hazards and taking appropriate preventive measures to reduce risks.

- Communicating Effectively – Handling communication in high-pressure situations, ensuring all team members are informed and aware of safety procedures.

- Time Management in Critical Tasks – Balancing tasks under time pressure while maintaining accuracy and safety standards.

These types of practical scenarios test your ability to think critically, make decisions under pressure, and implement solutions that align with safety regulations and best practices. Mastery of these situations is key to demonstrating competence and ensuring success in your role.

How to Stay Calm During the Exam

Maintaining composure during a high-pressure situation is essential for achieving optimal performance. The ability to stay calm not only enhances focus but also helps in making better decisions when under stress. With proper preparation and strategies, you can manage anxiety and approach the task at hand with clarity. Below are some practical techniques to help you stay calm during the assessment process.

1. Practice Relaxation Techniques

One effective way to combat nerves is by practicing relaxation techniques, such as deep breathing, mindfulness, and progressive muscle relaxation. These methods help reduce physical tension and calm your mind before and during the task.

- Deep Breathing: Inhale slowly for 4 counts, hold for 4 counts, then exhale for 4 counts. Repeat this cycle a few times to restore your focus.

- Mindfulness: Focus on the present moment. Take a few seconds to observe your surroundings and your breathing, which can center your thoughts.

- Progressive Muscle Relaxation: Tense and release different muscle groups to alleviate physical stress.

2. Time Management and Strategy

Effective time management can prevent you from feeling rushed or overwhelmed during the process. By allocating appropriate time for each section or task, you ensure that you can pace yourself and stay focused throughout.

| Task | Time Allocation |

|---|---|

| Initial Review | 5 minutes |

| Answering Questions | 15 minutes per section |

| Final Review | 5 minutes |

By sticking to a clear plan, you can manage your time wisely and reduce the pressure. This approach helps ensure you don’t miss any important steps and can focus without feeling rushed.

3. Positive Visualization

Visualizing success before starting can improve confidence and reduce anxiety. Picture yourself calmly answering questions, managing any challenges, and successfully completing the task. Positive visualization can help reinforce a calm and focused mindset, leading to a smoother experience.

By integrating these techniques, you can maintain a sense of control, manage stress, and increase your chances of performing at your best during the entire process.

What Happens After Passing Safe Lift 2

Successfully completing the required assessment opens up various opportunities for individuals looking to advance their skills and credentials. After passing, there are several key steps to take that will help solidify your expertise and prepare you for real-world application. This section explores the outcomes and next steps following successful completion of the program.

1. Receive Certification

Upon passing, you will receive an official certification. This document serves as proof of your knowledge and readiness to perform in the relevant field. The certification is often recognized by employers and regulatory bodies, making it an important addition to your professional credentials.

- Official certificate issued after successful completion

- Recognition from industry-specific organizations

- Boost to professional qualifications

2. Career Opportunities and Advancement

Passing the assessment can open doors to new job opportunities or promotions within your current organization. It enhances your qualifications and demonstrates your commitment to safety and operational standards, which is highly valued across various sectors.

- Increased job prospects

- Potential for salary increases

- Eligibility for specialized roles or leadership positions

3. Ongoing Training and Development

Achieving certification is just one step in the journey. To maintain proficiency and stay up to date with industry standards, ongoing training is essential. Many organizations offer additional learning modules or refresher courses to help individuals continue to grow in their roles.

- Regular refresher courses to keep knowledge current

- Opportunities for advanced certifications

- Access to specialized workshops and seminars

4. Greater Confidence and Job Satisfaction

With the certification in hand, individuals often experience greater confidence in their abilities and job performance. This sense of competence can lead to higher levels of job satisfaction, as they feel more capable in managing tasks and responsibilities in their work environment.

In summary, passing the assessment not only provides formal recognition of your abilities but also offers tangible benefits in terms of career growth, ongoing development, and personal satisfaction.

Resources for Further Learning

Continued learning is crucial to staying ahead in any field, especially in areas related to operational safety and procedures. While completing the necessary training provides a solid foundation, expanding your knowledge through additional resources can enhance your expertise. This section highlights useful materials and platforms for further study and skill development.

1. Online Courses and Certifications

There are a variety of online platforms offering courses that cover essential topics and advanced concepts related to operational standards, safety procedures, and risk management. These resources are ideal for individuals looking to deepen their understanding or obtain additional certifications.

- Coursera – Offers a wide range of safety and operational courses from top universities.

- Udemy – Provides affordable courses focused on workplace safety and equipment handling.

- edX – Features courses designed by industry experts, focusing on practical applications and regulatory standards.

2. Industry-Specific Books and Manuals

Books and manuals provide comprehensive insights into industry practices, standards, and methodologies. They are valuable references that can be consulted for in-depth learning and guidance.

- “The Safety Management Handbook” by Dr. Frederick R. C. is an excellent resource for understanding safety protocols and management strategies.

- “Industrial Safety and Health Management” by C. Ray Asfahl offers practical advice for safety professionals across various sectors.

- “Workplace Safety Handbook” by Dr. K. G. Smith outlines critical safety strategies, risk assessment techniques, and operational tips.

3. Government and Regulatory Websites

Government websites and regulatory bodies offer a wealth of free resources, including guidelines, safety regulations, and best practice manuals. These websites are vital for staying up to date with legal requirements and compliance standards in the field.

- OSHA (Occupational Safety and Health Administration) – Provides comprehensive resources on workplace safety regulations.

- ISO (International Organization for Standardization) – Offers safety and operational standards that are internationally recognized.

- National Safety Council (NSC) – Offers resources, courses, and certifications related to workplace safety and risk management.

4. Forums and Professional Communities

Engaging with others in the field through forums and professional groups is an excellent way to stay informed and discuss real-world challenges. These platforms allow individuals to share experiences, ask questions, and collaborate on improving operational procedures and safety standards.

- Safety Discussion Forums on Reddit – A community of professionals discussing safety practices and procedures.

- LinkedIn Groups – Join specialized groups focused on safety practices, workplace regulations, and industry trends.

- Professional Organizations – Examples include the American Society of Safety Professionals (ASSP) and the International Safety Equipment Association (ISEA).

By utilizing these resources, you can continue to build on your knowledge, keep up with industry changes, and refine your skills in ensuring safe and efficient operations.

Frequently Asked Questions About Safe Lift 2

As individuals prepare for certification and further training in operational safety, many questions arise about the process, requirements, and expectations. This section addresses some of the most common inquiries related to the training and assessment process. These answers aim to clarify any uncertainties and help you approach the process with confidence.

1. What is the purpose of this certification?

The primary goal of this certification is to ensure that individuals are equipped with the necessary knowledge and skills to safely operate and manage equipment in various work environments. It emphasizes safety procedures, risk management, and compliance with industry standards, helping individuals and organizations minimize hazards and promote efficient practices.

2. Who needs to take this training?

This training is typically required for individuals working in fields where the safe operation of equipment is critical. This includes industries like construction, logistics, manufacturing, and maintenance, among others. It is essential for anyone who is responsible for handling equipment or overseeing operational tasks that involve risk management and safety protocols.

3. How long does it take to complete the training?

The duration of the training varies depending on the provider and the specific program. On average, it can take anywhere from a few days to several weeks to complete, depending on the depth of the material covered. Some programs offer both in-person and online learning options, which may affect the overall length of time required.

4. What materials are needed for preparation?

Preparation for this training typically involves studying manuals, industry-specific safety standards, and taking part in practical exercises. Some programs may also provide practice tests or study guides to help individuals understand the types of topics covered. It is also recommended to review regulations from government bodies and relevant safety protocols before starting the program.

5. Is there a renewal or re-certification process?

Yes, in many cases, certification needs to be renewed periodically. This ensures that individuals are up to date with the latest regulations, safety practices, and technological advancements. The frequency of renewal can vary by industry, but it is typically every 2-5 years. Continuing education and refresher courses may also be required for re-certification.

6. How do I know if I am ready for the assessment?

Feeling prepared for the assessment often comes down to how well you understand the key concepts and can apply them to real-world situations. Reviewing the study materials, practicing safety procedures, and taking mock tests will give you a better idea of your readiness. Many training providers also offer self-assessment tools to evaluate your understanding of the content before the official assessment.

7. What happens if I don’t pass the test?

If you do not pass the test on your first attempt, many programs offer the opportunity to retake the assessment after additional preparation. Some organizations may provide feedback or offer resources to help you focus on areas where you may need improvement. Don’t be discouraged–taking the time to revisit the material and understanding the practical application of safety standards can greatly improve your chances on the next attempt.

8. Are there any prerequisites for taking the training?

In general, there are no specific prerequisites to start the training, though having a basic understanding of workplace safety can be beneficial. Some programs may recommend prior experience in the field or a basic level of physical fitness, especially if the training involves practical, hands-on exercises. It’s best to check with the training provider for any specific requirements.

If you have additional questions or need further clarification, it is always a good idea to contact the training provider directly. They can provide you with more detailed information and guidance based on your specific situation and needs.