In many workplaces, understanding safety protocols and the proper handling of hazardous materials is crucial. For those looking to work in environments with chemical substances, achieving certification in safety procedures is a key step. This training not only ensures compliance with legal requirements but also contributes to a safer working environment for all employees.

Preparing for safety assessments involves mastering various topics such as hazard identification, protective measures, and emergency response actions. With proper guidance and study, individuals can efficiently navigate the testing process and gain the necessary credentials to demonstrate their competence in workplace safety practices.

Successful completion of this certification requires a solid grasp of the system’s structure, symbols, and classifications. By focusing on key areas, candidates can increase their chances of passing the assessment and become fully prepared to manage risks effectively within their workplace.

Workplace Safety Certification Overview

Achieving certification in workplace safety is an essential step for individuals working with hazardous materials. This process ensures that employees are equipped with the knowledge to identify and manage risks effectively. The certification covers a range of critical topics, from understanding dangerous substances to knowing how to respond in emergencies.

The assessment consists of various sections designed to test the candidate’s grasp of safety protocols, hazard identification, and the proper use of protective equipment. It is structured to evaluate both theoretical knowledge and practical understanding of safety practices in the workplace.

Preparation is key to success in this process. Candidates must familiarize themselves with the key concepts, symbols, and labeling systems used to classify hazardous materials. By focusing on the core areas, individuals can feel confident in their ability to demonstrate their understanding during the assessment.

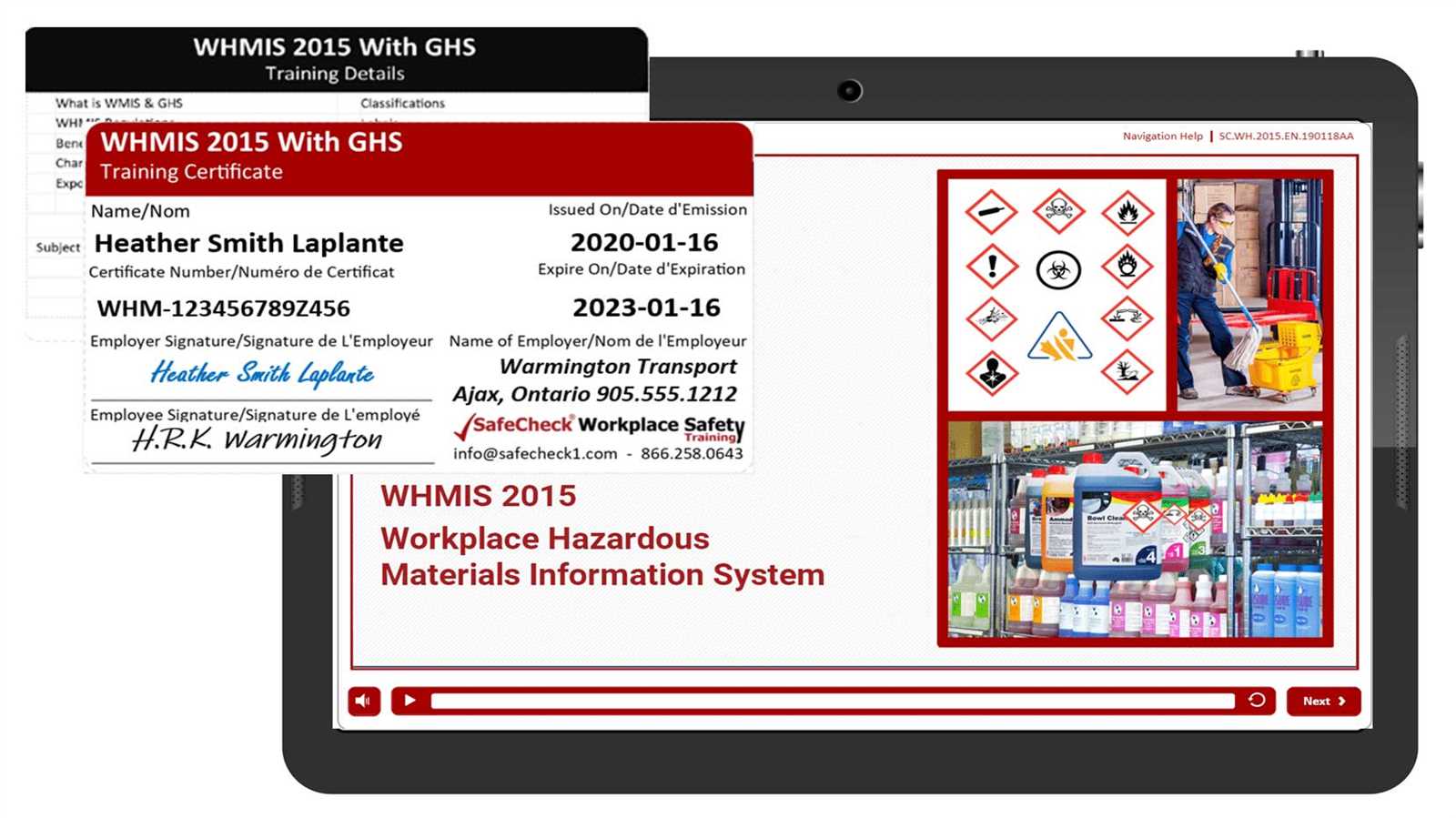

Upon completing the process, candidates receive certification that validates their competence in handling hazardous situations. This certification is not only a requirement for some industries but also serves as a valuable asset for ensuring workplace safety and health standards are upheld.

What Is Workplace Hazard Communication

Workplace hazard communication is a crucial system designed to protect workers from exposure to dangerous chemicals and materials. It provides guidelines on how to identify hazardous substances, interpret warning labels, and understand safety procedures. This system is essential in ensuring the safety and health of employees in environments where chemicals are handled or stored.

The system includes a variety of tools, including labels, safety data sheets (SDS), and pictograms, which are used to communicate the risks associated with various substances. By properly implementing these tools, employers can reduce the risk of accidents and create a safer working environment for all employees.

| Tool | Description |

|---|---|

| Labels | Provide crucial information about the hazards of materials, including handling instructions and first-aid measures. |

| Safety Data Sheets (SDS) | Offer detailed information about the chemical properties, storage requirements, and emergency procedures related to substances. |

| Pictograms | Visual symbols that represent specific hazards associated with chemicals, helping workers quickly recognize risks. |

By familiarizing workers with these elements, this communication system ensures that they can safely handle, store, and dispose of hazardous materials. It also enables employers to meet regulatory requirements and promote a culture of safety in the workplace.

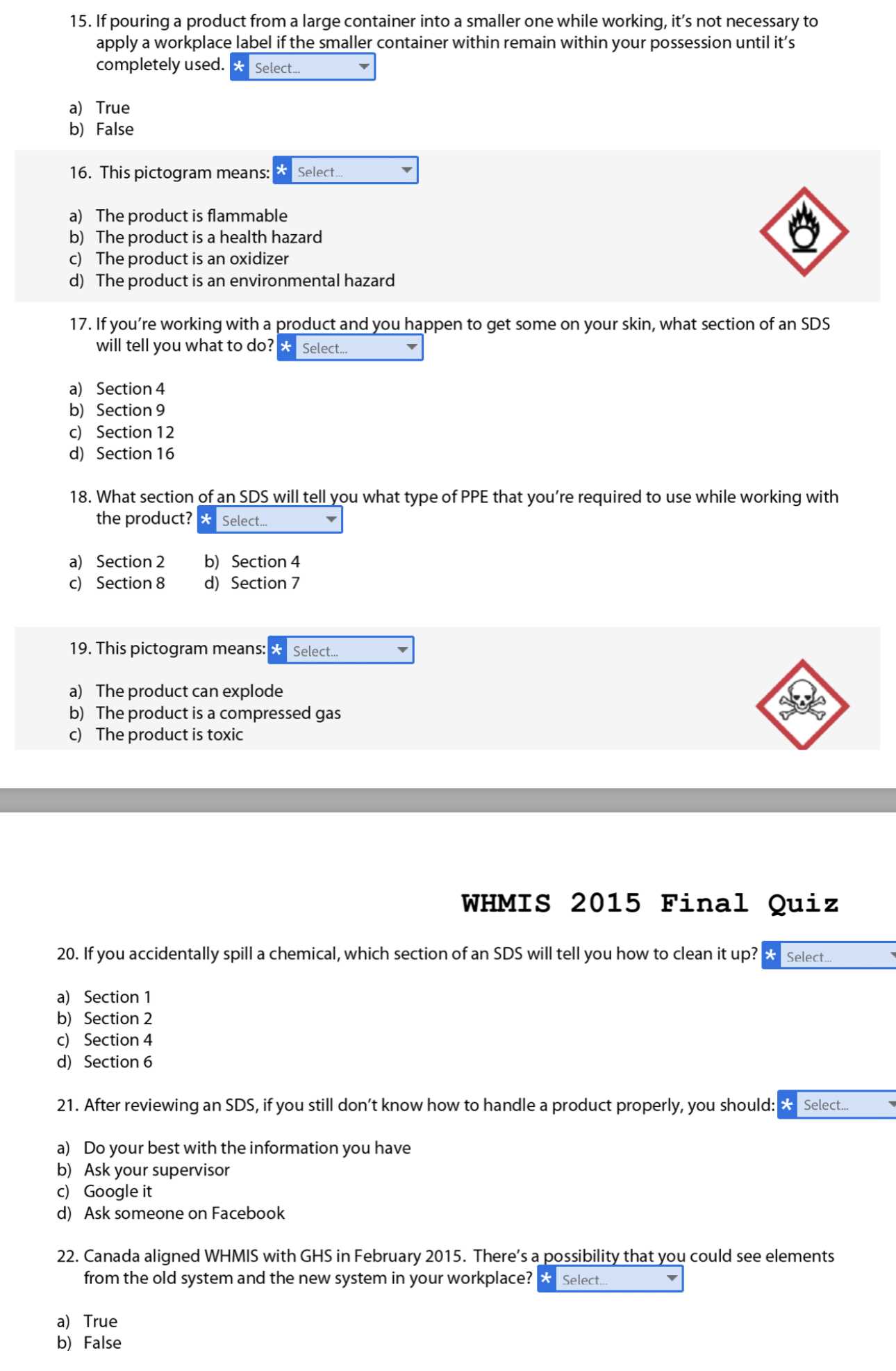

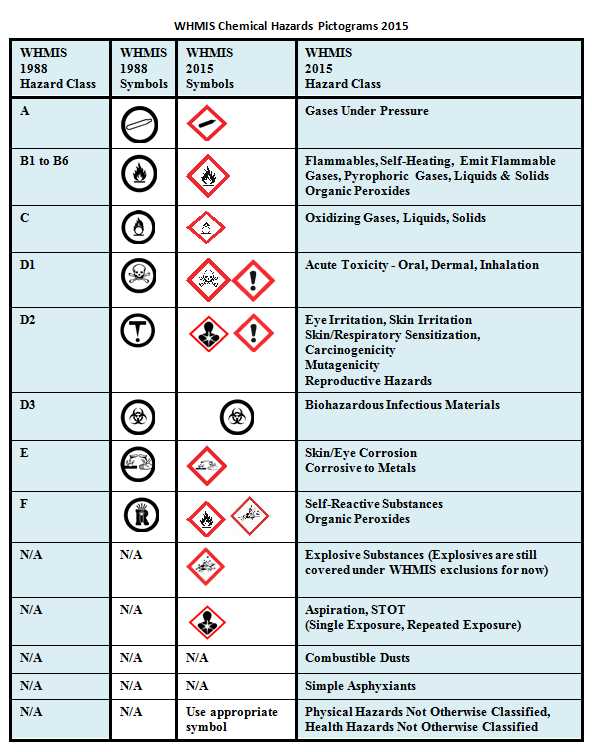

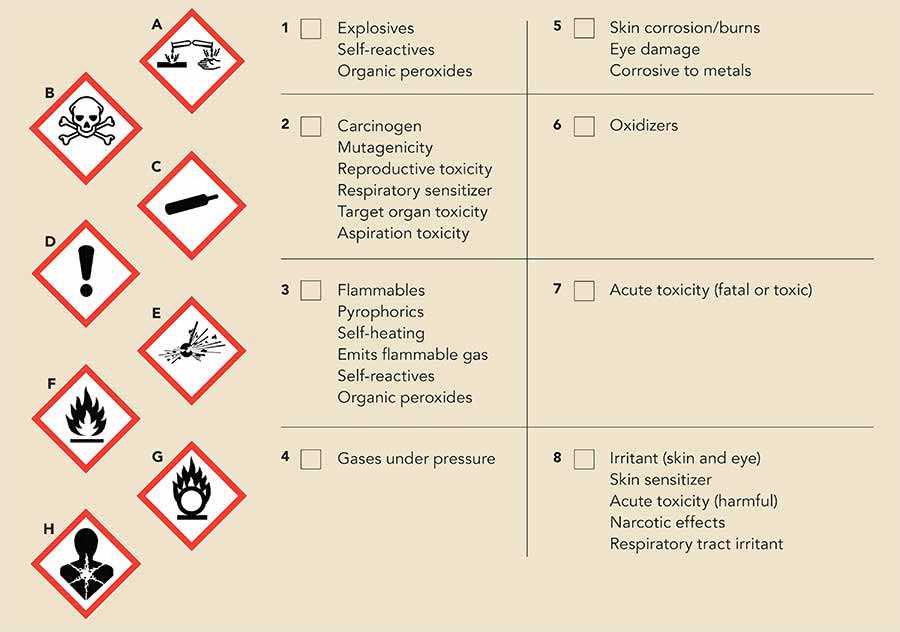

Understanding Workplace Hazard Symbols

In workplaces where chemicals and hazardous materials are present, symbols play a critical role in communicating the potential dangers. These visual indicators help workers quickly recognize risks and take appropriate safety measures. Understanding these symbols is essential for maintaining a safe environment and ensuring compliance with safety regulations.

Each symbol represents a specific type of hazard, such as toxicity, flammability, or corrosiveness. By understanding the meaning behind these images, workers can better assess the materials they are handling and follow necessary precautions. These symbols are standardized to ensure consistency and clear communication across various industries.

Key Symbols include:

| Symbol | Description |

|---|---|

|

Indicates materials that can cause severe damage to skin, eyes, or other substances. |

|

Represents materials that can easily catch fire under certain conditions. |

|

Warns of long-term health effects such as cancer, respiratory issues, or reproductive harm. |

Recognizing and interpreting these symbols can significantly reduce the likelihood of accidents in environments where hazardous substances are present. It is essential that workers are trained to identify these symbols and understand the necessary safety precautions associated with each one.

Key Requirements for Workplace Safety Certification

To become certified in workplace safety, individuals must meet certain criteria that demonstrate their knowledge and ability to safely handle hazardous materials. This certification ensures that workers are equipped with the necessary skills to identify, manage, and mitigate risks associated with chemicals and other dangerous substances in the workplace.

Successful candidates must complete a training program that covers a wide range of topics, from hazard identification to emergency response protocols. The program typically includes theoretical lessons, practical exercises, and an assessment to test the understanding of key safety concepts.

Key requirements for certification include:

- Completion of a recognized safety training course

- Understanding of hazard classification and labeling systems

- Knowledge of personal protective equipment (PPE) and its proper use

- Familiarity with safety data sheets and their role in risk management

- Ability to recognize and react to hazardous situations effectively

After meeting these requirements, individuals typically receive a certificate that validates their ability to work safely with hazardous materials. This certification is often required by employers and regulatory bodies to ensure a safe working environment.

Importance of Workplace Hazard Communication

Ensuring safety in environments that involve hazardous substances is crucial for the well-being of workers. A robust system of hazard communication helps to identify and mitigate risks, allowing employees to safely manage chemicals and other dangerous materials. This system serves not only to protect individuals but also to comply with legal and regulatory standards aimed at reducing workplace accidents.

When properly implemented, a clear communication system enables workers to understand the hazards they may encounter and the precautions needed to avoid accidents. It helps organizations prevent injuries, illnesses, and fatalities that can result from exposure to toxic chemicals, fires, or other dangerous situations.

Furthermore, a well-structured safety system fosters a culture of awareness and responsibility, where everyone from management to front-line workers understands the importance of safety. This creates a more productive and positive work environment, as employees feel confident in their ability to work safely and efficiently.

Common Workplace Safety Certification Topics

When preparing for a workplace safety certification, it is essential to cover a broad range of topics that focus on hazard recognition, risk management, and safe handling practices. The certification process evaluates a candidate’s understanding of the various components necessary to maintain a secure environment in workplaces where hazardous materials are present.

Hazard Classification and Labeling Systems

One of the key topics involves understanding the classification of hazardous materials and interpreting their labels. Candidates must be able to identify symbols that represent different types of risks, such as toxicity, flammability, and corrosiveness. Labeling systems are essential tools for ensuring that workers can quickly assess the hazards associated with chemicals and take the appropriate precautions.

Safety Data Sheets (SDS)

Another critical area is the knowledge of safety data sheets. These documents provide detailed information about the properties of hazardous substances, including their handling, storage, and emergency procedures. Understanding how to read and interpret SDS is vital for any employee working with chemicals, as it enables them to respond appropriately to emergencies and minimize potential risks.

Additional topics may include personal protective equipment (PPE), safe storage practices, and emergency response procedures, all of which are essential for ensuring the safety of workers handling hazardous materials.

How to Prepare for Workplace Safety Certification

Proper preparation is essential for achieving certification in workplace safety, especially for those working with hazardous substances. Familiarizing yourself with the core topics and understanding the key concepts will not only increase your chances of success but also ensure that you are ready to handle potential risks effectively in the workplace.

Steps to Get Ready

To effectively prepare for the certification process, follow these steps:

- Study the Safety Standards: Familiarize yourself with the classification of hazards, labeling systems, and safety data sheets. Understand the various symbols and their meanings to quickly identify risks.

- Learn About Protective Measures: Review the different types of personal protective equipment (PPE) and when to use them. Proper use of PPE is a critical aspect of maintaining safety.

- Practice with Scenarios: Go through potential emergency scenarios and understand how to respond appropriately. Knowing how to react in case of exposure or accidents is vital.

- Take Online Courses or Workshops: Many online resources offer practice tests and interactive learning that can help reinforce key concepts and prepare you for the assessment.

Study Resources

There are a variety of resources available to assist in your preparation:

- Official safety training manuals and handbooks

- Interactive online practice quizzes and mock tests

- Workshops and seminars conducted by safety organizations

- Safety videos and instructional guides

By consistently reviewing these materials and practicing the key concepts, you’ll be better prepared for the certification process and confident in your ability to work safely with hazardous materials.

Top Tips for Passing Workplace Safety Certification

Successfully achieving certification for workplace safety requires more than just memorizing facts. It’s about understanding the material thoroughly, applying the knowledge in real-world situations, and being able to recall key information under pressure. With the right approach, you can ensure that you are fully prepared to pass the certification assessment and confidently handle hazards in your workplace.

Key Tips for Success:

- Focus on Understanding, Not Just Memorizing: Instead of only memorizing facts, focus on grasping the concepts behind hazard classification, labeling systems, and safety protocols. Understanding the “why” and “how” will help you apply this knowledge in any situation.

- Review Safety Symbols and Labels: These are a major part of the assessment. Ensure you can identify and understand the meaning behind each symbol, as this knowledge is essential for workplace safety.

- Practice with Sample Questions: Use practice questions or mock tests to familiarize yourself with the type of content you may encounter. This will help reduce anxiety and improve your confidence when taking the actual test.

- Know Emergency Procedures: Be prepared to answer questions about how to respond in case of an emergency. Understanding proper procedures for spills, fires, and exposure incidents is critical.

- Take Breaks and Stay Calm: Studying in short, focused sessions and taking regular breaks will keep your mind fresh. Stay calm and confident, as stress can hinder your ability to recall information.

By following these tips and committing to the learning process, you will increase your chances of success and be well-prepared to safely handle hazardous materials in any workplace.

Workplace Safety Certification Assessment Structure

The structure of a workplace safety certification assessment is designed to test an individual’s understanding of key concepts related to hazard management, safe handling of materials, and emergency response procedures. The assessment ensures that candidates have a solid grasp of the safety protocols required to work with hazardous substances in various environments.

Typically, the certification process consists of multiple-choice questions, scenario-based problems, and practical exercises. These components are meant to assess both theoretical knowledge and practical application in real-world situations. The goal is not only to evaluate if you understand the safety measures but also if you can effectively apply them in a work setting.

The assessment is generally divided into the following sections:

- Hazard Identification: This section tests your ability to recognize different types of hazards, such as chemicals, flammable materials, and corrosive substances.

- Safety Data Sheets (SDS): Questions in this section focus on interpreting and using safety data sheets to understand the properties and handling procedures of hazardous materials.

- Personal Protective Equipment (PPE): This part evaluates your knowledge of various protective equipment and its correct use to minimize exposure to hazards.

- Emergency Response: Scenario-based questions assess your understanding of how to respond to incidents such as spills, fires, or exposure to toxic substances.

To successfully pass the assessment, you will need to demonstrate a thorough understanding of these topics and be able to apply them in real-world contexts. Preparing with these key areas in mind will increase your chances of success and help you ensure safety in any workplace.

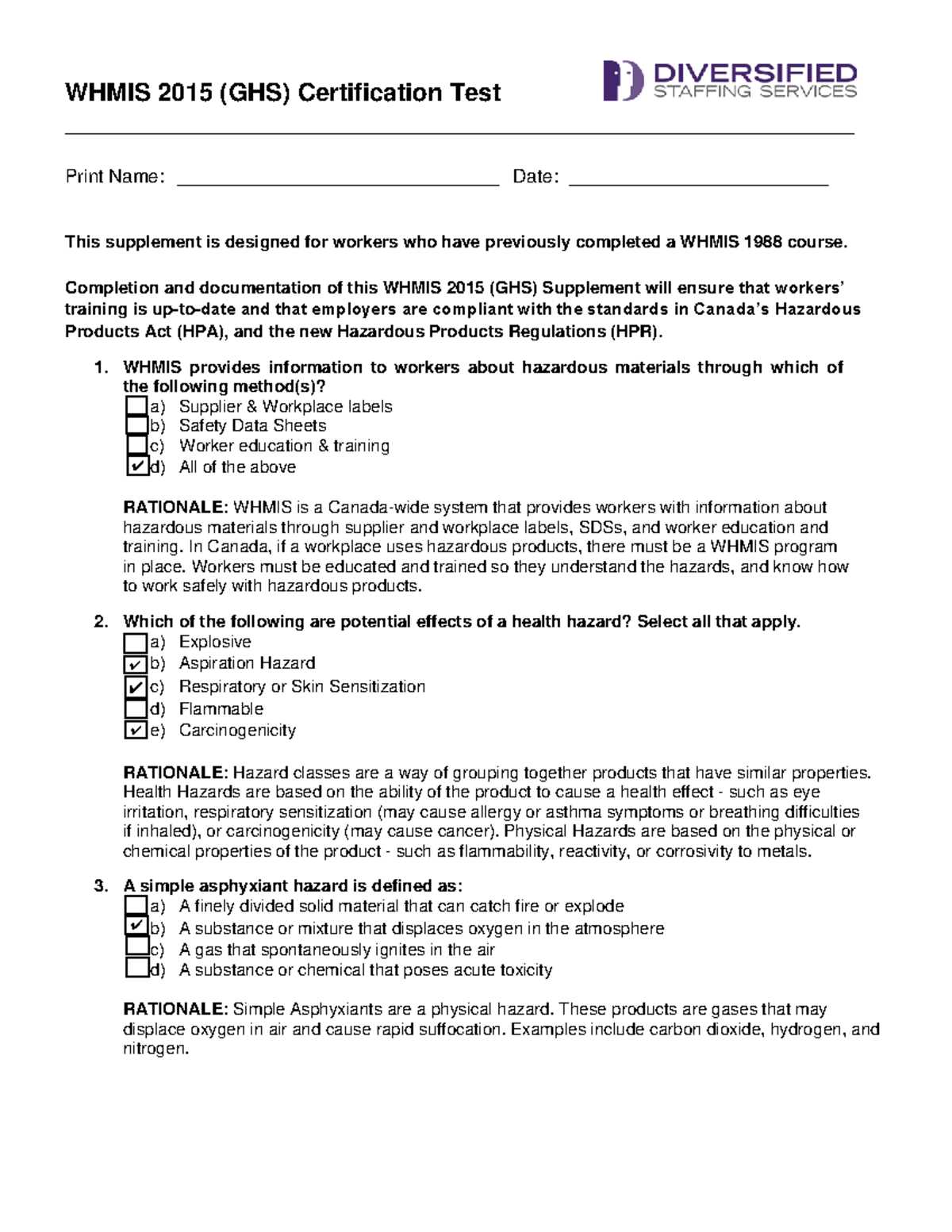

Safety Data Sheets and Workplace Safety

Safety Data Sheets (SDS) are a crucial part of ensuring workplace safety, especially when handling hazardous materials. These documents provide essential information on the properties, handling, and potential risks associated with substances used in various industries. They serve as a key resource for workers, supervisors, and emergency responders to understand how to safely interact with chemicals and other potentially dangerous materials.

SDSs are designed to provide standardized information that helps ensure safe handling practices and reduces the risk of accidents or health issues in the workplace. They are required by law and must be accessible to all workers who may come into contact with hazardous substances. The information provided in SDSs helps workers understand what protective equipment is needed, how to deal with spills or accidents, and the correct storage and disposal procedures.

| Section | Description |

|---|---|

| Identification | Provides the product name, manufacturer’s details, and the recommended uses of the substance. |

| Hazard Identification | Describes the health, physical, and environmental risks associated with the substance. |

| Composition/Information on Ingredients | Lists the chemical composition of the substance and the hazardous ingredients. |

| First Aid Measures | Details first aid procedures for exposure to the substance, including skin, eye, or inhalation contact. |

| Handling and Storage | Provides guidelines for safe handling, transportation, and storage of the substance. |

| Exposure Control/Personal Protection | Lists recommended protective equipment and control measures to prevent exposure. |

In addition to the SDS, employers must ensure that employees are properly trained to interpret and use the information provided. This training helps prevent accidents and ensures that workers are well-prepared to handle hazardous materials safely. Familiarity with SDSs is essential for anyone working in environments where chemical exposure is a risk, as it allows for informed decision-making and promotes overall workplace safety.

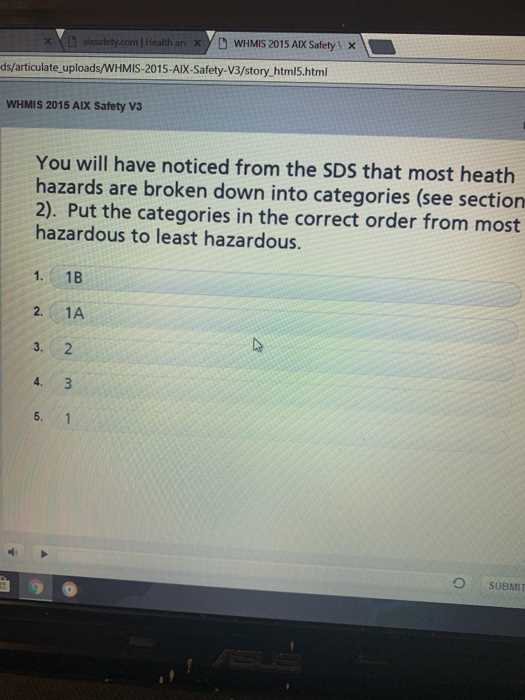

Types of Hazardous Materials Covered

Various substances can pose risks in the workplace, from chemicals and biological agents to physical hazards. It’s essential for workers to understand the types of hazardous materials they may encounter, as each type requires specific handling, storage, and protective measures. These materials are classified based on their physical and health risks, ensuring that employees are aware of the dangers and can take appropriate precautions.

The following categories represent the most common types of hazardous materials found in many industries:

Chemical Hazards

- Flammable Materials: Substances that can easily catch fire when exposed to heat, spark, or flame.

- Corrosive Substances: Materials that can damage living tissue or materials like metal upon contact.

- Reactive Chemicals: Substances that may undergo dangerous reactions when exposed to other chemicals or certain conditions.

- Toxic Chemicals: Substances that can cause harm to health or even death when ingested, inhaled, or absorbed through the skin.

Physical Hazards

- Explosive Materials: Substances that can rapidly release energy, causing damage to the surrounding area.

- Compressed Gases: Gases stored under high pressure that can be dangerous if mishandled or released improperly.

- Radioactive Materials: Substances that emit harmful radiation, which can cause severe health issues over time.

Each of these categories requires careful attention and the use of appropriate safety measures. Identifying the risks associated with hazardous materials and understanding how to mitigate them is crucial to maintaining a safe working environment. Workers should always refer to Safety Data Sheets (SDS) for detailed information about specific materials they may handle.

Common Mistakes to Avoid in Certification Tests

When preparing for a certification test related to workplace safety and hazardous material handling, many individuals make common errors that can significantly impact their performance. Recognizing these mistakes beforehand can help test-takers improve their chances of success and avoid unnecessary stress. Understanding the format, managing time effectively, and approaching each question with care are essential for passing with confidence.

Here are some of the most frequent mistakes to watch out for:

- Rushing Through Questions: It’s easy to feel pressured by the time limit, but rushing through the test often leads to careless mistakes. Take the time to read each question thoroughly before selecting an answer.

- Ignoring Instructions: Every test has its own set of instructions that must be followed. Skipping or misinterpreting these guidelines can lead to incorrect answers or missed points. Always read the instructions carefully.

- Overlooking Safety Protocols: Many individuals underestimate the importance of safety procedures in workplace-related tests. Don’t forget to review key safety practices and regulations–these topics often feature prominently in tests.

- Misinterpreting Complex Terminology: Safety and hazard-related terminology can be technical, but misunderstanding these terms can lead to errors. If unsure, try to break down complex terms or revisit related study materials.

- Not Reviewing Mistakes: After completing the test, many people neglect to review their answers. Going back over the questions you were unsure about can reveal gaps in knowledge and offer valuable learning opportunities.

By being mindful of these common pitfalls, you can improve your preparation strategy and approach the certification process with greater confidence. The key is to stay calm, focus on the content, and use your study materials to reinforce your understanding of essential concepts.

Training Resources and Courses for Hazardous Materials Handling

Effective training is essential for anyone working with or around hazardous substances in the workplace. Understanding how to manage risks, handle materials safely, and comply with safety protocols is crucial. There are numerous resources and courses available that provide in-depth knowledge and prepare individuals for certification in hazard safety practices.

These training programs are designed to give workers the tools they need to identify hazards, understand labeling systems, and follow procedures that ensure a safe work environment. Whether you’re looking for online courses, workshops, or comprehensive in-person training, various options are available to suit different learning preferences.

Available Training Options

- Online Courses: Many reputable platforms offer self-paced online courses that cover key topics like material identification, safety data sheets, and hazard classification. These are ideal for those seeking flexible learning opportunities.

- In-Person Workshops: For hands-on experience, in-person workshops provide a more interactive approach. These sessions often feature expert instructors and practical exercises.

- Corporate Training: Many organizations offer customized training for their employees, ensuring that specific workplace hazards are addressed. These sessions can be tailored to the needs of the company and the materials they handle.

Key Resources for Studying

- Official Guidelines: Government websites and safety organizations often publish official manuals and guidelines. These documents provide essential information regarding safety regulations and best practices.

- Interactive Learning Platforms: Some training programs use simulations, quizzes, and interactive modules to enhance learning and make the training more engaging.

- Reference Materials: Books, handouts, and downloadable PDFs are useful for review and quick reference. These materials often include detailed explanations of safety symbols, risk assessment methods, and emergency response procedures.

Choosing the right training program depends on your learning style and work environment. The key is to ensure that the course offers comprehensive coverage of the topics that are most relevant to your role, and that it is delivered by qualified instructors or through reputable organizations.

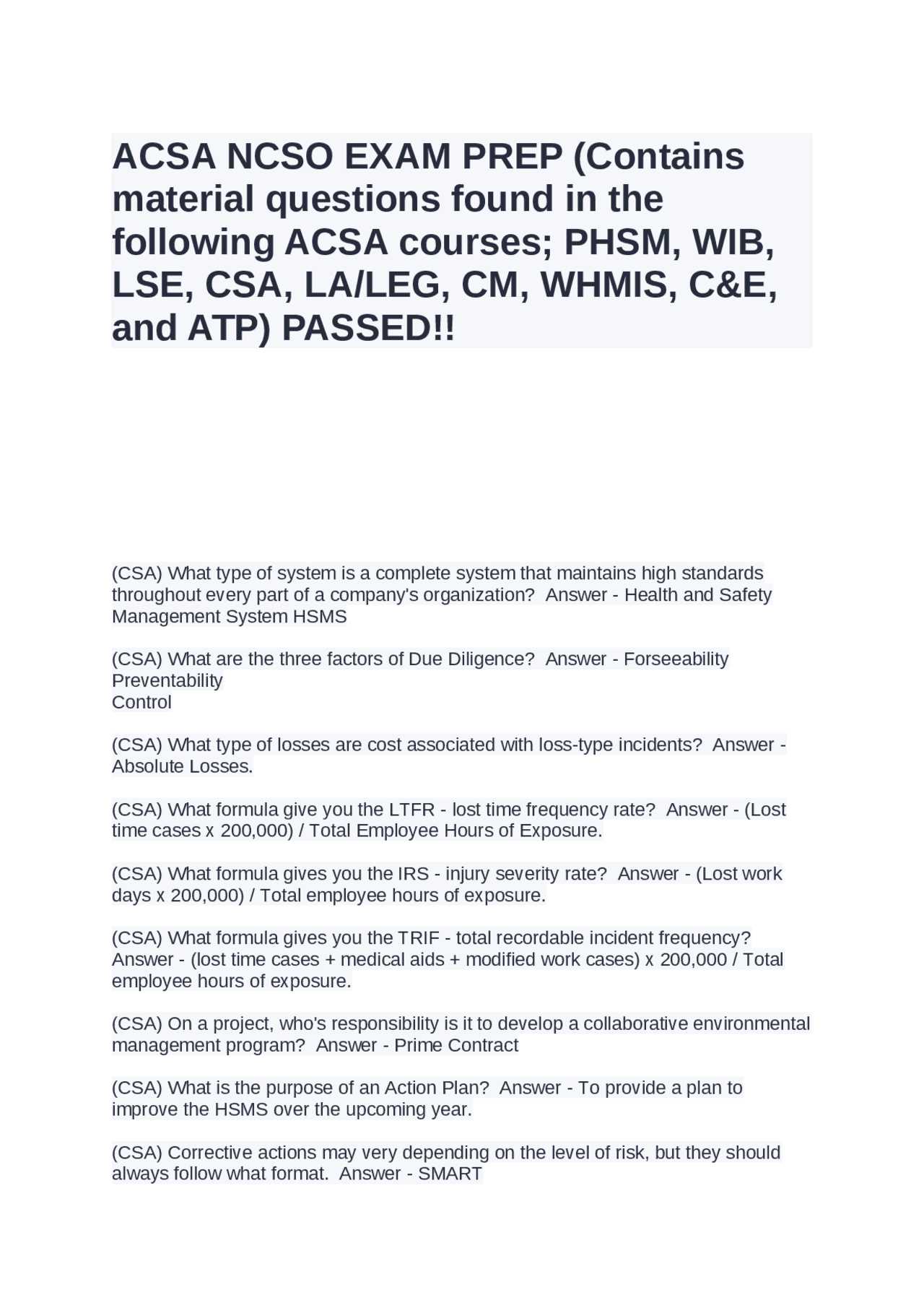

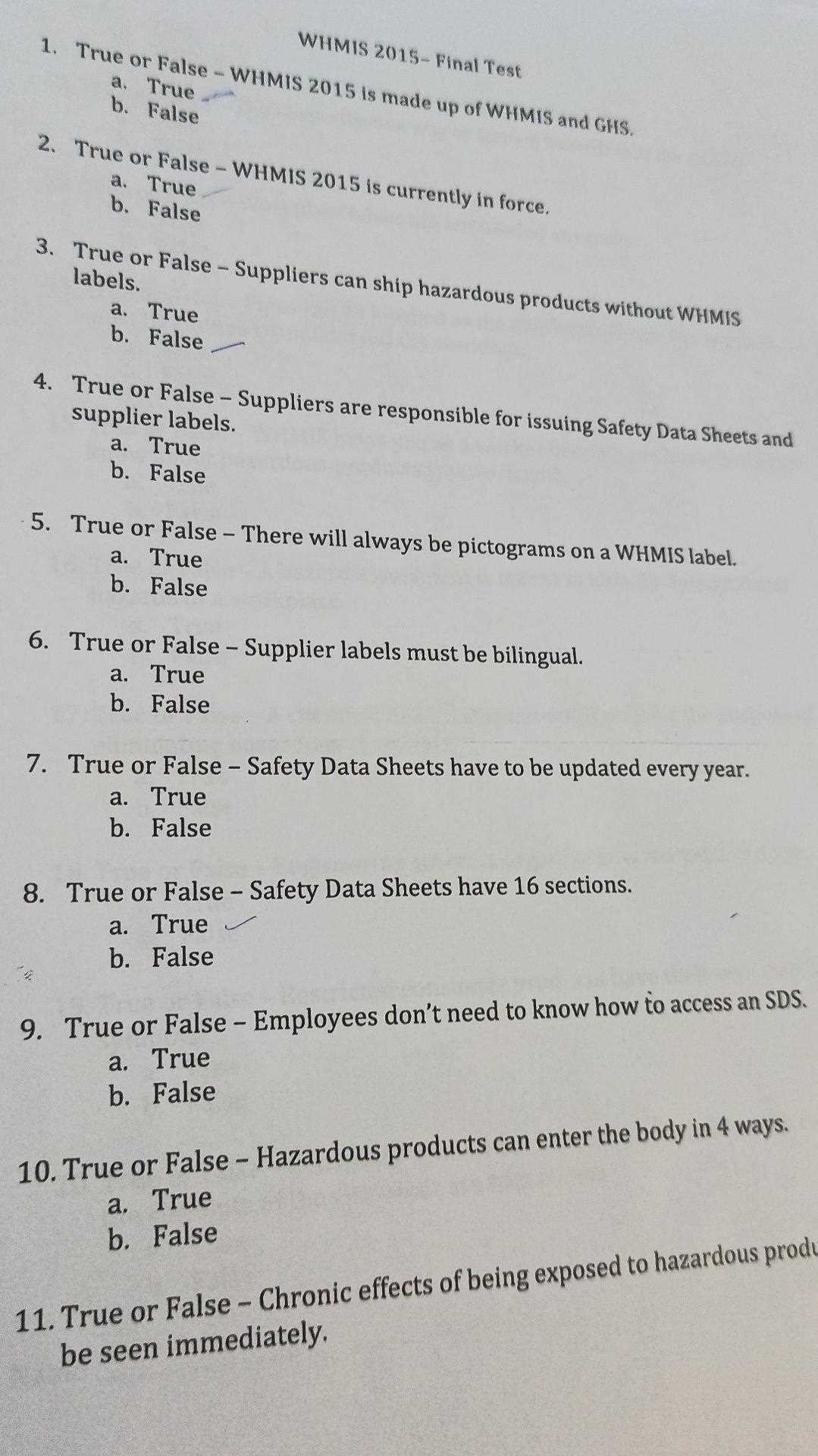

Practice Questions for Hazardous Materials Safety Certification

Preparing for a certification that focuses on safe handling and management of hazardous materials is an essential step in ensuring workplace safety. One of the best ways to solidify your understanding of key concepts is through practice questions. These questions simulate the types of scenarios and knowledge that may be tested, helping to reinforce learning and boost confidence before the actual evaluation.

Practice questions typically cover a range of topics, including hazard identification, the proper use of safety labels, and the correct interpretation of safety data sheets. By reviewing these questions, you can test your knowledge and identify areas that may require further study, ensuring you’re fully prepared for the assessment.

Sample Questions to Test Your Knowledge

- What symbol is used to indicate a material that is explosive or self-reactive?

a) Flame

b) Exploding bomb

c) Skull and crossbones

d) Corrosion

- Which of the following is the most appropriate action if a chemical spill occurs?

a) Evacuate the area and report the incident

b) Use a fire extinguisher immediately

c) Ignore it if it’s a small spill

d) Only report it to your supervisor after an hour

- What information can be found on a safety data sheet (SDS)?

a) Personal opinions of the manufacturer

b) Detailed instructions on how to use the chemical safely

c) Recommendations for using the chemical in different environments

d) A list of all other chemicals produced by the company

How to Use Practice Questions Effectively

- Understand the reasoning behind the answer: Don’t just memorize answers; understand why one choice is correct and why the others are not.

- Review explanations: If available, always read through the answer explanations to deepen your understanding of the concepts.

- Take regular practice tests: Continuously testing yourself helps to improve recall and reinforces your understanding over time.

By regularly practicing with these types of questions, you can improve both your knowledge and confidence, leading to better performance in the actual evaluation. This approach not only helps reinforce safety principles but also ensures that you are ready to handle real-world scenarios in the workplace.

Understanding Chemical Labeling Systems

Chemical labeling systems are vital tools used to communicate essential information about the hazards associated with chemicals in the workplace. These labels provide clear visual cues and detailed instructions on how to safely handle substances, ensuring that workers are aware of potential risks and can take necessary precautions. By interpreting these labels correctly, employees can significantly reduce the chance of accidents and injuries when interacting with hazardous materials.

Labels are designed to be straightforward and contain specific information that helps in identifying the substance and understanding its associated risks. Below are the primary elements typically included on a chemical label:

| Label Element | Description |

|---|---|

| Pictograms | These are graphic symbols that indicate the type of hazard a substance presents. Pictograms are easy to recognize and provide a quick way to assess the danger level, such as toxicity, flammability, or environmental hazards. |

| Signal Word | The signal word indicates the severity of the hazard. “Danger” signifies a more severe risk, while “Warning” is used for less severe hazards. |

| Hazard Statements | These statements describe the nature of the chemical’s risk, such as “may cause respiratory issues” or “highly flammable.” Hazard statements are standardized across industries for clarity and consistency. |

| Precautionary Statements | These instructions advise on how to handle the substance safely, including necessary protective measures and emergency actions in case of exposure or spills. |

By understanding the components of chemical labels, workers can identify and interpret the potential hazards quickly. This understanding is crucial for ensuring safety in environments where hazardous materials are handled, stored, or transported. Chemical labeling systems are designed to provide clear and concise information that helps prevent accidents and ensures that the appropriate safety measures are followed at all times.

Handling Emergencies and WHMIS

When hazardous substances are involved in workplace operations, it’s essential to be prepared for emergencies. Having a well-defined plan in place ensures that employees know how to respond effectively in case of accidents or exposures. The proper handling of emergencies can minimize risks to health, safety, and the environment. In such situations, knowledge of safety protocols, including the correct use of personal protective equipment (PPE) and the understanding of material hazards, becomes critical.

Key Emergency Procedures

Emergency responses in hazardous material incidents are guided by well-established procedures that focus on minimizing harm and ensuring the safety of all individuals. These procedures typically include:

- Evacuation Plans: Clear routes and procedures for evacuating personnel from hazardous areas.

- First Aid Measures: Immediate actions to treat injuries or exposure to harmful chemicals, such as administering first aid or calling emergency medical services.

- Containment: Steps to limit the spread of chemicals or hazardous substances in the event of a spill or leak.

- Notification: Informing emergency response teams, supervisors, or regulatory bodies about the situation promptly.

Using Safety Data Sheets (SDS)

In case of an emergency involving chemicals, Safety Data Sheets (SDS) provide crucial information to guide the proper response. SDS contain detailed information about the chemical’s properties, including its reactivity, toxicity, and recommended emergency handling procedures. Understanding how to access and interpret these documents is vital for ensuring an effective emergency response.

In summary, handling emergencies in environments with hazardous materials requires preparation, knowledge, and quick action. Understanding the proper procedures and utilizing available resources, such as Safety Data Sheets and emergency protocols, is essential for minimizing the impact of accidents and protecting everyone involved.

Why WHMIS 2015 Matters for Workers

The safety of workers in environments where hazardous materials are present depends on clear guidelines and effective training. Workers who understand the risks associated with various substances and know how to protect themselves can prevent accidents, injuries, and illnesses. A comprehensive safety program helps individuals recognize dangers, use protective equipment correctly, and respond appropriately in emergencies. It ultimately creates a safer and more efficient work environment for everyone.

Key Benefits for Workers

Effective training and awareness about hazardous materials can significantly reduce the risks workers face on the job. Here are some key reasons why it matters:

- Health Protection: Workers who are educated on the proper handling and storage of chemicals are less likely to suffer from long-term health issues like respiratory problems, skin conditions, or poisoning.

- Accident Prevention: Understanding the hazards of substances helps prevent accidental spills, leaks, or exposures. It enables workers to take proactive measures to avoid dangerous situations.

- Emergency Response: Proper knowledge empowers workers to act quickly and correctly in case of accidents, reducing the severity of injuries and environmental damage.

- Legal Compliance: Workers and employers must comply with safety regulations. Understanding the required safety standards ensures that both parties meet legal requirements, avoiding penalties and fines.

Building a Culture of Safety

By fostering awareness of safety procedures, organizations can build a culture where workers feel more confident in their roles and are more likely to take safety seriously. In workplaces where safety standards are prioritized, workers are more engaged and motivated to follow guidelines, resulting in fewer accidents and a healthier workforce.

In conclusion, workers’ well-being is directly tied to their understanding of the risks they face and the measures they must take to protect themselves. Training on the safe handling of hazardous substances is essential for maintaining a safe, productive, and legally compliant workplace.