In any food-related profession, understanding the proper procedures for maintaining a safe environment is crucial. Professionals must be equipped with the right knowledge to ensure hygiene, prevent illness, and manage risks that arise when handling consumables. Whether you’re just starting or preparing for a certification, it’s important to grasp the core principles that ensure public safety and health standards are met.

Key principles such as cleanliness, temperature control, and proper handling are critical to every aspect of the job. These guidelines help protect customers and ensure compliance with health regulations. For those looking to demonstrate their competence, understanding these standards is necessary to succeed and provide high-quality service. The following section covers important insights to help you prepare for any assessments related to safety practices in the workplace.

Food Safety Knowledge for Certification

When preparing for certification in safe practices, it’s essential to familiarize yourself with the common questions and topics that will be assessed. Understanding the key concepts and knowing the right responses to common scenarios can help ensure a smooth evaluation process. This section provides an overview of typical concepts that are tested, offering guidance for anyone looking to demonstrate proficiency in maintaining a safe environment.

| Topic | Key Focus |

|---|---|

| Temperature Control | Understanding safe temperature ranges for storing, cooking, and serving items. |

| Hygiene Practices | Proper hand washing, personal cleanliness, and health standards. |

| Cross-Contamination | Preventing harmful bacteria spread between raw and cooked items. |

| Cleaning Protocols | Techniques for sanitizing equipment, surfaces, and utensils effectively. |

| Health Regulations | Key legal and safety regulations that must be followed in any service setting. |

Mastering these topics is essential for success. By thoroughly preparing and familiarizing yourself with the most relevant principles, you can approach the certification process with confidence and knowledge.

Understanding the Certification Process

Obtaining the necessary qualifications to work in environments that involve the handling and serving of consumables requires a thorough understanding of key safety concepts. Certification ensures that workers possess the required knowledge to maintain hygiene, minimize risks, and comply with relevant health standards. This section will explore the importance of the certification and the process involved in obtaining it.

Why Certification Matters

Achieving certification in safe practices is essential not only for personal growth but also for the overall safety of the public. It guarantees that workers can identify potential hazards, implement preventive measures, and respond appropriately to different situations. This certification is often required by employers and regulatory bodies to ensure that establishments meet the required health and safety standards.

Steps to Obtaining Certification

The journey to certification involves completing a structured program, usually followed by an assessment of your knowledge. The program covers a variety of topics, from sanitation and personal hygiene to specific regulatory guidelines. Once the course is completed, the final evaluation determines whether the candidate is ready to handle the responsibilities safely. With the right preparation and dedication, anyone can successfully pass the assessment and earn the necessary credentials.

Importance of Passing the Assessment

Successfully completing the certification process is essential for anyone working in environments that require safe practices when handling consumables. It not only demonstrates competence but also ensures that individuals are equipped with the necessary knowledge to prevent risks, manage hazards, and maintain a healthy environment. This section highlights why achieving a passing score is crucial for both personal and professional growth.

Ensuring Public Safety

One of the primary reasons for passing the certification is to guarantee the safety and well-being of the public. Workers must understand proper hygiene, sanitation techniques, and how to handle items correctly to avoid contamination and foodborne illnesses. Without a solid foundation in these principles, the risk of unsafe practices increases, which could lead to health violations or worse, outbreaks.

Compliance with Legal Requirements

In many regions, passing the certification is not just a recommendation but a legal requirement for anyone involved in food-related services. Employers may require proof of certification before hiring, and failing to obtain it can prevent you from legally working in certain roles. Passing the assessment ensures that you meet local regulations and contribute to the establishment’s compliance with health and safety laws.

Common Questions in the Assessment

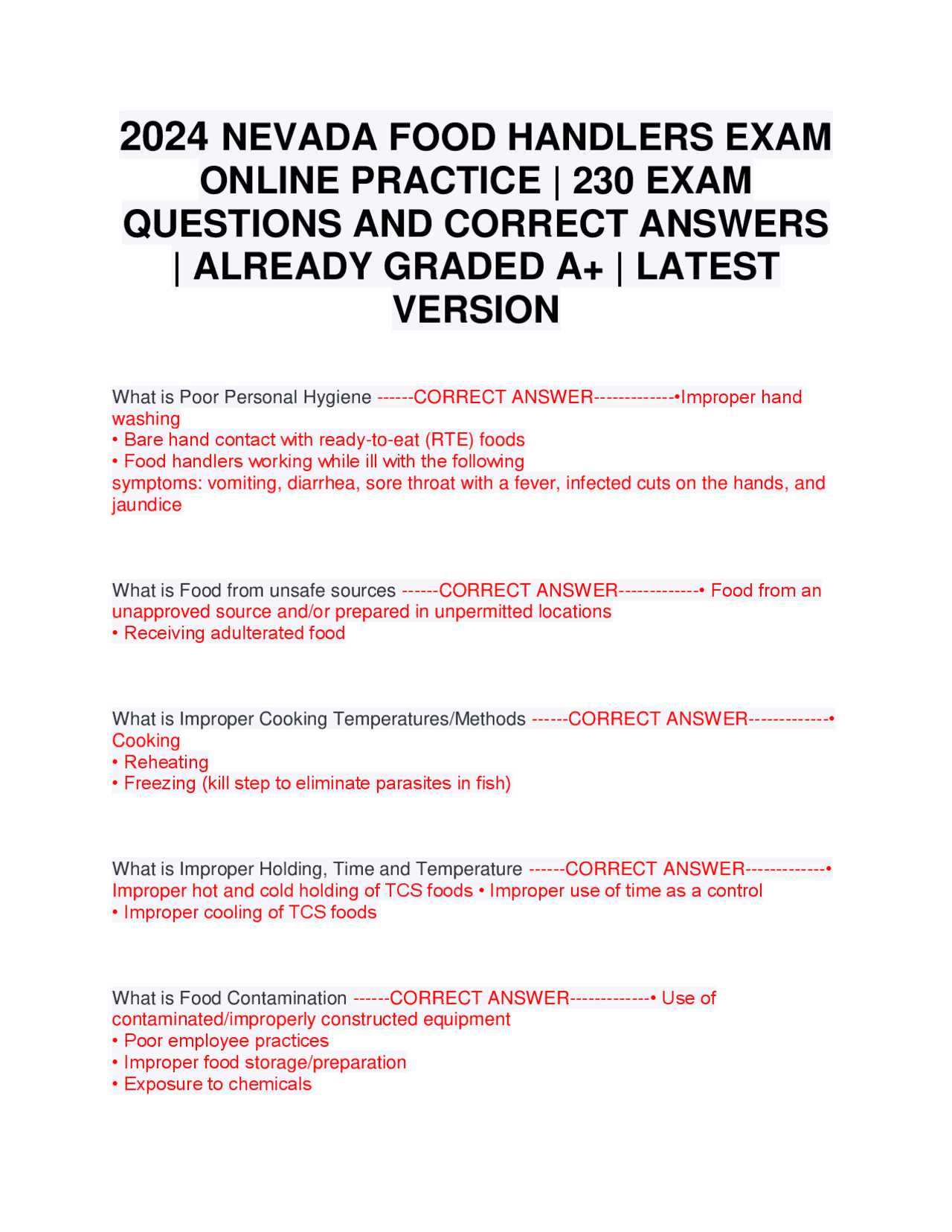

During the certification process, individuals are typically tested on a wide range of topics related to maintaining a safe and hygienic environment in the workplace. The questions often cover various key areas that are crucial for ensuring public health and preventing risks. Being familiar with these common queries can help prepare candidates for the evaluation and ensure they are confident when it’s time to demonstrate their knowledge.

Some questions focus on general hygiene practices, such as the correct methods for hand washing and the appropriate times for cleaning. Others may involve the identification of unsafe practices or conditions that could lead to contamination. Understanding how to handle specific materials, monitor temperatures, and properly sanitize equipment is also frequently addressed. A solid grasp of these concepts will greatly improve the chances of success and ensure that individuals are fully prepared for any scenario that might arise in their workplace.

Basic Safety Practices for the Workplace

Maintaining a clean and safe environment in any service or production setting is vital for protecting the health of consumers. Basic hygiene and safety practices are essential components of ensuring that risks are minimized and health standards are met. This section covers some fundamental procedures that every worker should know to prevent contamination, spread of illnesses, and maintain high-quality standards in their daily work.

Hand Hygiene and Personal Cleanliness

Proper hand washing is one of the most important practices in maintaining a safe environment. Hands should be washed frequently, especially after handling items, using the restroom, or touching surfaces that may be contaminated. It’s essential to follow a detailed process of washing, using both soap and water, and scrubbing all areas of the hands for at least 20 seconds. Additionally, workers should maintain good personal hygiene, such as wearing clean uniforms and keeping hair properly secured to avoid contamination.

Proper Handling of Materials and Equipment

Another critical aspect of safety is the correct handling of materials. Items such as tools, surfaces, and equipment should be cleaned and sanitized regularly to reduce the risk of harmful bacteria spreading. Workers must also ensure that materials are stored at appropriate temperatures and that there is a clear separation between raw and ready-to-eat items to prevent cross-contamination. Regular checks on equipment and environments can help avoid accidents and maintain a consistently safe workspace.

Illness Prevention Tips for Safe Practices

Preventing illness caused by improper handling or contamination is one of the primary responsibilities in any environment where consumables are prepared or served. By following proper protocols and taking simple precautions, workers can significantly reduce the risk of spreading harmful bacteria and viruses. This section outlines essential tips for minimizing the chances of illness and ensuring that safety standards are met in the workplace.

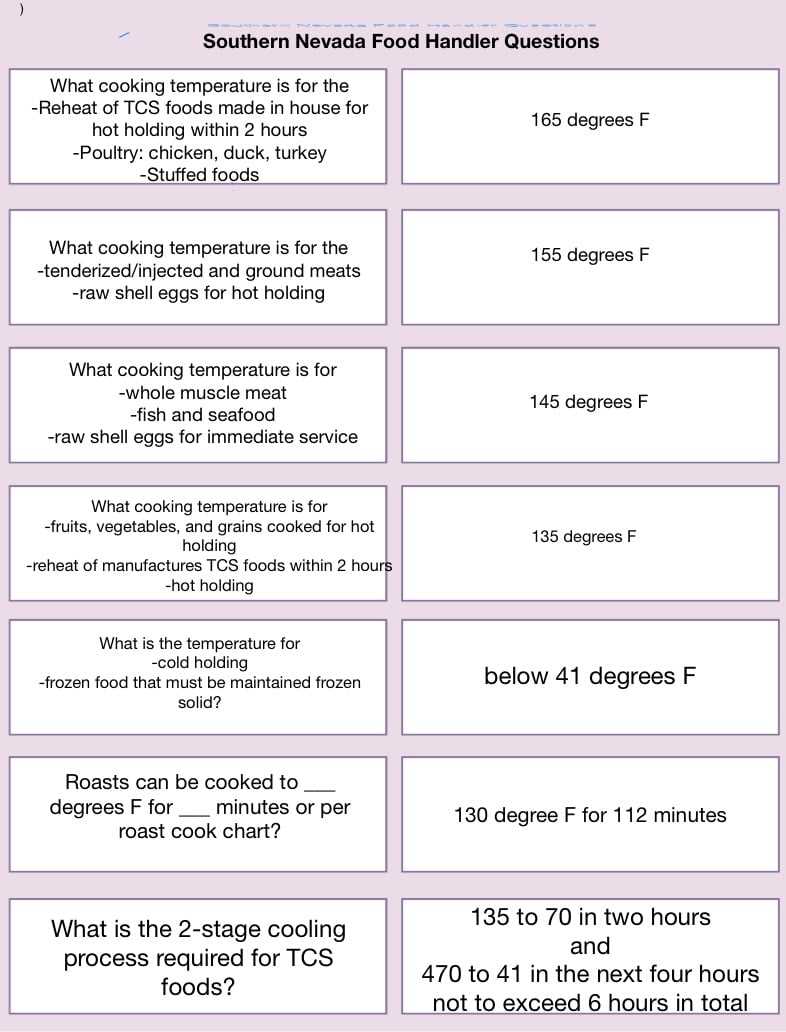

Maintaining Proper Temperature Control

One of the most effective ways to prevent the growth of harmful microorganisms is by keeping items at safe temperatures. Cold items should be kept at or below 40°F (4°C), while hot items should be stored at temperatures above 140°F (60°C). This helps to slow bacterial growth and ensures that items remain safe for consumption. It’s crucial to use thermometers regularly to monitor temperatures and avoid leaving perishables out for extended periods.

Cleanliness and Sanitation Protocols

Regular cleaning and sanitation of surfaces, utensils, and equipment play a significant role in reducing the risk of contamination. Workers should always clean surfaces that come into contact with items and ensure that all areas are sanitized according to health guidelines. Special attention should be given to high-touch areas like countertops, cutting boards, and refrigerators. Ensuring that workers wash their hands properly and wear gloves when necessary is equally important in maintaining a safe environment.

Cleaning and Sanitizing Procedures

Maintaining cleanliness and sanitization in any environment where consumables are handled is essential for preventing contamination and ensuring public safety. Proper cleaning procedures help remove dirt, grease, and visible debris, while sanitizing ensures that harmful microorganisms are effectively killed or reduced to safe levels. The following guidelines outline essential steps for keeping workspaces safe and hygienic.

Steps for Effective Cleaning

The cleaning process involves removing dirt, debris, and other visible contaminants from surfaces and equipment. Follow these steps to ensure a thorough cleaning:

- Remove all items from surfaces and equipment.

- Use hot water and detergent to scrub surfaces and remove grease, food particles, and dirt.

- Rinse surfaces thoroughly to remove any soap residue.

- Dry surfaces with clean towels or air-dry them to prevent recontamination.

Proper Sanitizing Techniques

Sanitizing is the next critical step, as it ensures that harmful pathogens are eliminated. Follow these guidelines to sanitize effectively:

- Use the appropriate sanitizing solution, such as chlorine bleach, quaternary ammonium compounds, or other approved chemicals.

- Ensure the solution is mixed according to manufacturer recommendations for effective results.

- Apply the sanitizing solution to cleaned surfaces and allow it to sit for the recommended contact time.

- Allow surfaces to air dry, as wiping them may reintroduce bacteria.

Adhering to these procedures regularly will help prevent the spread of harmful bacteria and maintain a safe working environment for both workers and consumers.

Handling Items at Safe Temperatures

Ensuring that consumables are kept at the correct temperatures is essential to prevent the growth of harmful microorganisms. Both too high and too low temperatures can lead to contamination, spoilage, and illness. This section provides guidance on maintaining proper temperature control throughout the handling, storing, and serving of products to ensure safety at all times.

| Temperature Range | Purpose |

|---|---|

| Below 40°F (4°C) | Store perishable items such as dairy, meat, and certain vegetables to prevent bacterial growth. |

| 40°F – 140°F (4°C – 60°C) | This range is considered the “danger zone” where bacteria grow rapidly; items should never remain in this range for extended periods. |

| Above 140°F (60°C) | Maintain hot items at these temperatures to prevent harmful bacteria from growing during service. |

It is essential to regularly check the temperatures of items using thermometers and take immediate action if items fall outside of the safe range. Proper storage, including refrigeration and heating, is crucial to maintaining the safety of all consumables. Additionally, items should not be left at room temperature for long periods, as this increases the risk of contamination. By following these practices, safety can be ensured throughout the handling process.

Recognizing Cross-Contamination Risks

Cross-contamination occurs when harmful microorganisms are transferred from one surface or item to another, leading to potential health hazards. This can happen through direct contact or through indirect means, such as contaminated utensils or equipment. Understanding the common risks associated with cross-contamination is crucial in preventing illness and ensuring safety in any setting where consumables are prepared or served.

| Risk Factor | Preventive Measure |

|---|---|

| Raw and Cooked Items | Always store and prepare raw ingredients separately from cooked or ready-to-eat items. |

| Contaminated Utensils and Equipment | Use different utensils for raw and ready-to-eat items, and clean them thoroughly between uses. |

| Unwashed Hands | Always wash hands thoroughly before handling different items, especially after touching raw products. |

| Improper Storage | Store raw items on lower shelves in refrigerators to prevent drips onto ready-to-eat items. |

Being aware of these common risks and taking the necessary precautions to avoid them can significantly reduce the chances of cross-contamination. Regular training, maintaining proper hygiene, and using separate equipment for different types of items are all essential steps in ensuring a safe environment for everyone involved.

Proper Hand Washing Techniques

Hand washing is one of the most effective ways to prevent the spread of harmful bacteria and viruses. Properly washing hands removes dirt, debris, and pathogens that can cause illness. It is essential to follow the correct procedure to ensure that hands are thoroughly cleaned and sanitized before handling any items or surfaces. This section outlines the necessary steps for effective hand hygiene.

The process begins with wetting hands under clean, running water, followed by applying soap. Hands should then be scrubbed for at least 20 seconds, paying close attention to all areas, including the backs of the hands, between the fingers, and under the nails. After rinsing thoroughly, dry hands with a clean towel or air dryer to avoid recontamination. It is equally important to wash hands after certain activities, such as using the restroom, handling waste, or touching potentially contaminated surfaces.

Role of Personal Hygiene in Safety

Maintaining proper personal hygiene is essential for ensuring safety in any environment where consumables are prepared or served. Personal cleanliness directly impacts the prevention of contamination and the spread of harmful pathogens. When workers follow hygiene protocols, they contribute to reducing the risk of illness and ensuring that items are handled in a safe manner. This section explores the significant role personal hygiene plays in maintaining a safe workplace.

Good hygiene practices include regular hand washing, wearing clean and appropriate clothing, keeping hair properly secured, and avoiding direct contact with consumables if one is ill or has open wounds. Additionally, workers should be cautious about touching their face, especially their mouth, nose, or eyes, to avoid transferring germs to items. By adhering to these standards, workers help maintain a healthy environment and prevent the transmission of harmful bacteria and viruses.

Understanding Safety Regulations

Regulations that govern hygiene and safety practices in environments where consumables are handled are crucial for protecting public health. These rules are designed to ensure that all necessary precautions are taken to minimize risks, maintain cleanliness, and ensure that all procedures are followed correctly. Understanding these guidelines is vital for anyone working in industries where safe handling is a priority. This section explains key aspects of these regulations and how they contribute to a safe working environment.

Key Requirements and Standards

Compliance with local regulations is necessary to prevent violations and ensure public trust. These rules often cover aspects such as proper sanitation, temperature control, and cross-contamination prevention. Workers must be trained in these areas and regularly evaluated to ensure they are meeting the required standards. Regulations also typically include specifications on how long items should be stored, at what temperature, and when they should be discarded to prevent safety risks.

Training and Certification

Many safety regulations require that workers complete certification programs to demonstrate their understanding of best practices and legal requirements. These programs ensure that employees are not only aware of the rules but also capable of implementing them in the workplace. Certification may be required by law in some regions and industries, and it helps to maintain high standards of safety in environments where public health is at risk.

How to Prepare for the Evaluation

Preparing for an evaluation in hygiene and safety procedures is essential for ensuring that you have the necessary knowledge and skills to meet industry standards. Adequate preparation not only boosts your confidence but also helps you pass with ease. This section covers practical steps to help you get ready for the assessment, ensuring that you are well-prepared to demonstrate your understanding of essential safety practices.

Review Key Concepts

Focus on the main principles of cleanliness, temperature control, and contamination prevention. Make sure you understand the proper methods for handling materials, cleaning and sanitizing surfaces, and preventing cross-contamination. It’s also important to familiarize yourself with safety regulations and how they apply to your specific role. Reviewing these concepts through study guides and practice materials can help reinforce your knowledge and identify areas where you may need further improvement.

Practice with Sample Questions

Many evaluations include questions that test your ability to apply safety protocols in real-life scenarios. Practice by working through sample questions or quizzes that cover a wide range of topics, from hygiene practices to regulations. This helps you get used to the format of the assessment and builds your ability to quickly identify correct answers during the actual evaluation.

Effective Study Strategies for Success

To succeed in any evaluation related to safety and hygiene practices, it is crucial to adopt efficient study techniques. Well-organized preparation, active learning, and consistent review will ensure that you fully grasp the necessary concepts and perform well during the assessment. In this section, we outline several strategies that can help you maximize your study sessions and achieve success.

Organize Your Study Sessions

Planning your study time in advance is a key factor for effective learning. Here are a few tips to organize your study sessions:

- Set specific goals for each session, focusing on one or two key concepts at a time.

- Break down large topics into smaller, manageable chunks to avoid feeling overwhelmed.

- Establish a schedule to ensure regular study intervals and prevent last-minute cramming.

Active Learning Techniques

Active learning involves engaging with the material in a way that goes beyond passive reading or note-taking. Consider these strategies:

- Practice recall: Instead of re-reading notes, try to recall key concepts from memory.

- Teach others: Explaining concepts to a peer or colleague helps reinforce your understanding.

- Use visual aids: Create charts, diagrams, or flashcards to reinforce concepts visually.

By implementing these strategies, you will be better prepared and confident when it comes time for the assessment.

How to Read Safety Labels

Understanding safety labels is essential for ensuring that materials are stored, prepared, and handled properly. These labels contain important information regarding the proper use, handling, and storage of various items, helping to reduce the risk of contamination or illness. In this section, we will explore how to read and interpret these labels effectively, ensuring that you can make informed decisions about the safety of the items you handle.

Key Elements of a Safety Label

Safety labels typically include several crucial pieces of information. Here are the most common components you should look for:

- Storage Instructions: Indicates the ideal temperature range for storing an item to maintain its safety and quality.

- Expiration Date: Shows when the item should be used by, helping to prevent the consumption of outdated products.

- Handling Instructions: Provides guidelines for safely preparing, serving, or storing the item to avoid contamination.

- Allergen Information: Alerts you to potential allergens that the item may contain, ensuring safe handling for individuals with sensitivities.

Interpreting Label Symbols

Many safety labels also include symbols that offer quick, visual information. Some of the most common symbols include:

- Temperature Symbols: Indicate whether an item should be refrigerated, frozen, or kept at room temperature.

- Use-By Date: Marks the latest date by which the item should be consumed or discarded to ensure safety.

- Cross-Contamination Risk: A symbol warning you to avoid mixing raw and cooked items.

By understanding these key elements, you can better ensure that you follow the proper safety measures when working with different materials. Always refer to the label to make informed choices and minimize the risk of unsafe handling.

Key Terms in Safe Practices

To ensure proper safety and hygiene, it is important to understand the terminology commonly used in the context of handling materials and preventing contamination. Knowing these key terms helps individuals follow protocols effectively and maintain a clean, safe environment. This section outlines essential terms that are crucial for anyone working in environments where safety is a priority.

Important Terminology

Here are some of the most critical terms to be familiar with:

- Cross-Contamination: The transfer of harmful bacteria or pathogens from one surface or item to another, usually through direct contact.

- Temperature Control: The process of maintaining specific temperature ranges to prevent the growth of harmful microorganisms in items.

- Sanitization: The process of cleaning surfaces and tools to reduce the number of harmful microorganisms to a safe level.

- Personal Hygiene: Practices such as regular hand washing, wearing appropriate attire, and keeping hair secured to avoid contamination.

Other Relevant Terms

In addition to the basics, understanding these terms will help you comply with safety practices:

- Contaminant: Any harmful substance that can cause illness when introduced to consumables.

- Allergen: A substance that can cause an allergic reaction in some individuals, such as nuts, dairy, or gluten.

- Holding Temperature: The temperature at which an item should be maintained for safe consumption or storage.

Being familiar with these terms helps you navigate best practices and apply the right techniques to ensure a safe and hygienic environment. Always remember that understanding these key concepts is foundational to maintaining safety and preventing risks in the workplace.

After the Evaluation: What’s Next

Once you’ve completed the assessment, it’s important to understand the next steps to take in order to ensure your success. Whether you pass or need to retake the evaluation, there are several actions you can take to continue improving your knowledge and skills. This section will guide you through what to do after the evaluation and how to maintain a high level of expertise in safety and hygiene practices.

Results and Next Steps

After the assessment, you will receive your results, which will determine if you’ve met the required standards. Here’s what you should consider next:

- Review the Feedback: If provided, go over any feedback or areas of improvement mentioned. This helps you identify where you can improve for future evaluations.

- Celebrate Your Success: If you pass, take the time to acknowledge your hard work and commitment to safety.

- Prepare for Retakes: If you didn’t pass, don’t be discouraged. Review the areas where you struggled and focus your study efforts on those topics.

Maintaining Knowledge and Skills

Passing the assessment is just the beginning. To ensure continued success and safety, ongoing education and practice are necessary. Consider these steps to maintain and expand your knowledge:

- Keep Learning: Stay up to date with the latest safety guidelines and best practices through online resources, workshops, or seminars.

- Regular Practice: Continuously apply the knowledge you’ve gained in your day-to-day activities to reinforce your understanding.

- Renew Certifications: Many certifications require renewal after a certain period. Be sure to check the expiration date and complete any necessary re-certification steps.

By staying proactive and committed to learning, you will ensure that you not only pass the evaluation but also uphold the highest safety standards in your work environment.

Tips for Maintaining Your Certification

Once you have successfully completed the required program and received your certification, it’s essential to ensure that your knowledge remains up to date and that your credentials stay valid. Maintaining certification involves ongoing efforts to stay informed, improve your skills, and comply with industry standards. This section provides tips to help you keep your certification current and continue practicing safely and effectively.

Stay Informed and Continue Learning

To maintain your certification, it’s important to stay updated on the latest safety protocols and guidelines. Here’s how you can ensure you’re always learning:

- Follow Industry Updates: Regularly check for updates on safety regulations and best practices to ensure compliance with the latest standards.

- Take Continuing Education Courses: Many certifications require or recommend periodic educational courses to keep your skills fresh and relevant.

- Attend Workshops and Seminars: Participate in professional workshops or seminars to deepen your understanding and learn new techniques.

Keep Documentation Organized

It’s crucial to keep track of your certification and any related documents to ensure it remains valid. Here are some steps to help you stay organized:

- Monitor Expiry Dates: Certifications often have an expiration date. Mark it on your calendar and start the renewal process ahead of time.

- Store Certification Safely: Keep a copy of your certification in a secure place, such as a digital file or a physical folder, for easy access when needed.

- Record Continuing Education: Document any courses, seminars, or training sessions you attend to meet renewal requirements.

By following these tips, you can ensure that your certification remains valid, and you continue to uphold high standards of safety and professionalism in your field.