Ensuring safety in environments where food is prepared and served is critical for public health. Knowledge of the correct procedures and techniques plays a vital role in preventing contamination and ensuring hygiene standards are met. Whether you’re working in a professional kitchen or managing food service, understanding the core concepts is crucial for both safety and efficiency.

In this section, we will explore the essential concepts that form the foundation of safe practices in food preparation. We will focus on key aspects such as temperature control, sanitation, and methods to avoid cross-contamination. These principles are not only fundamental to maintaining a clean and safe workspace but also help to meet regulatory requirements and pass necessary assessments.

By the end of this guide, you will have a clear understanding of the most common protocols used in the industry. This will help you succeed in achieving compliance and performing tasks with confidence, ensuring both quality and safety in every aspect of your role.

Food Safety Knowledge Guide

Mastering the fundamental principles of hygiene and proper procedures in a kitchen or service environment is essential for success. Whether you’re preparing for an evaluation or looking to refresh your understanding, knowing the correct practices ensures a safe and efficient operation. This guide will walk you through the core topics that are commonly assessed, helping you to perform tasks with precision and confidence.

Core Concepts to Understand

There are several crucial aspects that form the backbone of safe practices in any food-related workspace. These are the areas most often covered in assessments and include both theoretical knowledge and practical application. The key concepts include:

- Temperature Regulation: Understanding the importance of maintaining correct temperatures to prevent harmful bacteria growth.

- Personal Hygiene: Ensuring cleanliness through regular handwashing, appropriate attire, and proper handling of materials.

- Cross-Contamination Prevention: Techniques to avoid contamination between raw and ready-to-eat items.

- Proper Storage: How to store ingredients at the right temperatures and in safe conditions to maintain quality.

- Sanitation Procedures: Guidelines for cleaning and disinfecting surfaces and utensils to minimize health risks.

Effective Study Tips

Preparing for a safety evaluation requires a strategic approach. Here are some practical tips to help you study and retain the necessary information:

- Review Key Regulations: Familiarize yourself with local and national safety regulations to understand the legal requirements.

- Practice Scenarios: Create real-life scenarios where you apply the principles, such as managing temperature controls or sanitizing workspaces.

- Use Study Aids: Leverage study guides, practice quizzes, and flashcards to test your knowledge.

- Stay Updated: Ensure you are aware of the latest guidelines and updates in safety standards.

Key Principles of Food Safety

In any environment where consumables are prepared or served, maintaining hygiene and preventing contamination are critical. The practices that ensure the cleanliness and safety of ingredients and prepared dishes are fundamental to health and well-being. These principles are designed to reduce risks and protect consumers from harmful pathogens that may cause illness.

Temperature Control

One of the most essential aspects of maintaining safety is regulating the temperature of ingredients and meals. Keeping perishable items at the correct temperature prevents the growth of harmful bacteria. This includes:

- Hot Holding: Ensure cooked items are kept at temperatures above 140°F (60°C) to prevent bacterial growth.

- Cold Holding: Refrigeration should be at or below 40°F (4°C) to preserve the safety of perishable items.

- Cooking Temperatures: Certain ingredients need to reach specific temperatures to eliminate pathogens (e.g., poultry at 165°F or 74°C).

Cross-Contamination Prevention

Another key practice is preventing cross-contamination, which occurs when harmful microorganisms spread from one surface or item to another. This can be avoided by:

- Separation: Keep raw ingredients, particularly meats, separate from ready-to-eat foods.

- Proper Cleaning: Regularly clean all work surfaces, utensils, and equipment to avoid residue buildup.

- Personal Hygiene: Wash hands regularly, particularly before preparing food or after handling raw items.

Common Mistakes in Food Handling

Even with the best intentions, certain actions can lead to safety risks in environments where consumables are prepared and served. Recognizing and avoiding common errors is essential to maintain hygiene standards and protect against contamination. These mistakes often stem from a lack of awareness, improper training, or simple oversight.

Some of the most frequent issues include improper temperature control, inadequate sanitation, and neglecting to follow proper procedures for separating ingredients. These lapses can significantly increase the risk of harmful microorganisms affecting the quality and safety of meals. Awareness of these mistakes can help in preventing them and ensuring a safer working environment.

- Neglecting Temperature Checks: Failing to regularly monitor cooking and storage temperatures can lead to the growth of harmful bacteria.

- Inadequate Hand Hygiene: Skipping handwashing or improper sanitizing can transfer pathogens to surfaces and food.

- Cross-Contamination: Using the same utensils or surfaces for raw and cooked items without proper cleaning increases the risk of spreading harmful bacteria.

- Storing Ingredients Improperly: Not storing perishable items at the right temperatures or mixing raw and ready-to-eat products can lead to spoilage and contamination.

- Overlooking Expiry Dates: Using expired ingredients can compromise the safety and quality of the final product.

Understanding Temperature Control Guidelines

Proper temperature regulation is crucial for maintaining the safety and quality of ingredients and prepared meals. If temperatures are not managed correctly, harmful microorganisms can grow rapidly, leading to contamination and foodborne illness. Understanding the guidelines for temperature control helps ensure that items are cooked, stored, and served in a safe manner, preventing the risks associated with improper temperature management.

The following temperature ranges are essential to follow to prevent the growth of harmful bacteria:

- Hot Holding: Keep hot items at temperatures above 140°F (60°C) to prevent bacterial growth.

- Cold Holding: Store perishable items below 40°F (4°C) to slow down the growth of harmful pathogens.

- Danger Zone: The range between 40°F and 140°F (4°C to 60°C) is considered the “danger zone” where bacteria multiply most rapidly.

- Cooking Temperatures: Ensure that specific items reach the required internal temperature to kill harmful bacteria. For example, poultry should be cooked to 165°F (74°C).

To maintain these standards, regular monitoring is essential. Use thermometers to check temperatures at different stages of preparation, cooking, and storage. Proper equipment and accurate readings are vital in ensuring that items are kept at safe temperatures throughout their lifecycle.

Best Practices for Temperature Control

- Use Thermometers: Always check temperatures using a calibrated thermometer to ensure accuracy.

- Regular Monitoring: Perform regular checks, especially during high-volume periods, to avoid temperature fluctuations.

- Proper Cooling Techniques: Cool items rapidly by dividing large batches into smaller portions or using an ice bath.

- Store at Correct Temperatures: Immediately refrigerate perishable items after use and avoid leaving them at room temperature for extended periods.

Food Storage Best Practices

Proper storage of ingredients and prepared items is essential to prevent spoilage and contamination. Storing products at the correct temperature and in the right conditions helps preserve their quality and ensures they remain safe for consumption. Effective storage practices also minimize waste, extend shelf life, and reduce the risk of foodborne illnesses.

There are several key guidelines to follow to ensure safe and effective storage:

| Storage Type | Temperature Range | Best Practices |

|---|---|---|

| Refrigeration | Below 40°F (4°C) | Store perishable items promptly; avoid overloading the refrigerator to ensure proper air circulation. |

| Freezing | 0°F (-18°C) or lower | Freeze items in airtight containers; label with dates for tracking. |

| Dry Storage | Room Temperature (65°F to 75°F or 18°C to 24°C) | Store non-perishable items in a cool, dry place; ensure proper ventilation to avoid humidity buildup. |

| Wet Storage | Depends on item (usually cool and dry) | Keep products like fresh herbs in water; change the water regularly to maintain freshness. |

In addition to temperature control, organizing storage spaces is crucial. Store raw items separately from ready-to-eat products to avoid cross-contamination. Labeling items with their storage dates ensures that older products are used first, helping to prevent waste and ensuring safety.

Hand Hygiene and Food Safety

Maintaining proper hand hygiene is one of the most important practices to prevent the spread of harmful bacteria and viruses in environments where items are prepared and served. Hands come into contact with surfaces, ingredients, and utensils, making them a common source of contamination. Ensuring that hands are regularly cleaned and sanitized is essential for keeping everything safe and free from pathogens.

Handwashing is a simple yet effective measure that significantly reduces the risk of contamination. It is critical to follow proper procedures before and after certain activities to avoid transferring harmful microorganisms to products. Below are key guidelines for maintaining hygiene:

- When to Wash: Always wash hands before preparing meals, after handling raw ingredients, after using the restroom, or after touching waste.

- Proper Technique: Use warm water and soap, scrubbing all surfaces of the hands for at least 20 seconds, including between fingers and under nails.

- Hand Sanitizers: When soap and water are unavailable, use an alcohol-based hand sanitizer with at least 60% alcohol, but it should not replace regular handwashing.

Common Hand Hygiene Mistakes

Even with the best intentions, there are several common mistakes people make when it comes to hand hygiene:

- Not Washing Long Enough: Many people do not wash their hands for the recommended 20 seconds, which reduces the effectiveness of the process.

- Using Dirty Towels: Using towels or cloths that haven’t been sanitized can transfer bacteria back onto clean hands.

- Touching Surfaces After Washing: After washing, avoid touching faucets or doorknobs without a paper towel, as these surfaces can be contaminated.

By adhering to proper hand hygiene guidelines, the risk of contamination is greatly minimized, ensuring a safer environment for everyone involved.

Proper Food Preparation Techniques

Effective preparation is a key element in ensuring that meals are safe to consume and maintain their intended quality. The way ingredients are handled before cooking or serving plays a significant role in preventing contamination and ensuring safety. Proper techniques involve not only correct cutting and cooking methods but also maintaining a clean environment throughout the process.

Essential Steps for Safe Preparation

Following the right steps during meal preparation minimizes the risk of harmful bacteria and contaminants. The following practices are critical for ensuring safety:

- Cleanliness: Always wash hands, utensils, and surfaces before and after contact with raw ingredients.

- Separation: Keep raw and cooked items separate to avoid cross-contamination. Use different cutting boards for meats and vegetables.

- Use Correct Tools: Ensure that knives, peelers, and other tools are clean and in good condition before use.

Handling Ingredients with Care

In addition to general cleanliness, handling each type of ingredient properly is essential. Some tips include:

- Thawing: Thaw frozen items in the refrigerator, never on the counter, to prevent bacterial growth.

- Measuring: Measure ingredients accurately to ensure even cooking and prevent overcooking or undercooking.

- Storage: Store prepared ingredients at the right temperature and use within the recommended time frame to maintain their safety and quality.

Cross-Contamination Prevention Strategies

One of the most critical aspects of ensuring safety in environments where items are prepared is preventing the transfer of harmful pathogens between different surfaces, ingredients, and tools. This process of cross-contamination can lead to serious health risks if not effectively controlled. Implementing proper strategies to prevent it is essential for maintaining a hygienic and safe environment.

Key prevention strategies involve careful organization, cleaning, and segregation of ingredients, utensils, and surfaces. By taking proactive measures, it’s possible to eliminate or significantly reduce the chances of harmful microorganisms spreading during meal preparation.

| Strategy | Action | Best Practice |

|---|---|---|

| Separation of Raw and Cooked Items | Store raw and ready-to-eat products separately to prevent direct contact. | Use separate storage containers, cutting boards, and utensils for raw and cooked products. |

| Proper Cleaning of Tools | Clean knives, cutting boards, and other tools between uses. | Sanitize equipment with an appropriate disinfectant and wash thoroughly after each use. |

| Regular Surface Disinfection | Wipe down work surfaces frequently to remove any contaminating residues. | Use food-safe cleaning agents and ensure surfaces are completely dry after cleaning. |

| Personal Hygiene | Wash hands regularly, especially after handling raw items. | Follow strict handwashing protocols and wear gloves when needed. |

By incorporating these strategies into daily practices, the risk of contamination is greatly minimized, contributing to a safer and more hygienic environment for meal preparation.

Signs of Contaminated Food

Identifying when products have been compromised by harmful microorganisms is crucial to prevent health risks. Contaminated items may not always show visible signs, but there are key indicators to watch for that can help detect potential problems before consumption. Recognizing these signs early can help in taking corrective measures to avoid serious illnesses.

The most common signs of contamination are related to changes in appearance, smell, texture, or taste. Below are some common warning signs to look out for:

- Unusual Odor: A sour, rotten, or off-putting smell is a clear sign that something may be contaminated.

- Discoloration: Unexpected color changes, such as a greenish tint, mold growth, or darkening of the surface, may indicate spoilage.

- Slimy or Sticky Texture: A slimy or overly sticky texture on items that should be firm or dry is a sign of bacterial growth.

- Off Taste: A strange or sour taste when consuming an item can signal it has been compromised.

In addition to sensory indicators, temperature and handling practices can also contribute to contamination. If items have been stored improperly or for too long at unsafe temperatures, they are more likely to harbor harmful pathogens.

It’s important to always err on the side of caution when any of these signs are present. When in doubt, it is best to discard questionable items to avoid the risk of foodborne illnesses.

Why Personal Protective Equipment Matters

Personal protective equipment (PPE) plays a critical role in maintaining a safe environment in settings where items are prepared or handled. It serves as a barrier against contamination, injuries, and exposure to harmful substances. By using the right gear, individuals can protect both themselves and others from potential health risks.

The importance of PPE goes beyond simply meeting safety standards; it is about ensuring the well-being of workers, preventing cross-contamination, and maintaining overall hygiene. It provides an extra layer of defense against the spread of harmful microorganisms and other hazards that could arise during preparation and service.

Types of Personal Protective Equipment

Different environments require different types of PPE to address specific risks. The following are some of the most commonly used protective items:

- Gloves: Protect hands from direct contact with potentially contaminated surfaces or substances.

- Aprons: Shield clothing and skin from contaminants and prevent cross-contamination.

- Hair Nets or Caps: Prevent hair from falling into the work area or coming into contact with items.

- Face Masks: Reduce the risk of respiratory contamination and protect from airborne pathogens.

- Eye Protection: Guard against splashes or spills of harmful liquids.

Benefits of Using PPE

By consistently using personal protective gear, several key benefits are achieved:

- Health and Safety: Protects workers from injuries and exposure to harmful substances or pathogens.

- Hygiene Maintenance: Helps prevent the spread of contaminants between individuals and across surfaces.

- Regulatory Compliance: Ensures adherence to safety standards and legal requirements in workplace settings.

In any workplace, the use of PPE is essential for ensuring a safe, clean, and efficient environment, reducing the likelihood of contamination, and promoting a culture of health and safety.

Critical Safety Regulations to Know

In any environment where items are prepared, stored, or served, understanding and following safety regulations is essential to prevent contamination and ensure public health. These rules are designed to minimize risks, promote hygiene, and protect both workers and consumers. Compliance with these regulations not only ensures safety but also fosters trust and credibility in the establishment.

From temperature controls to proper sanitation, there are several key regulations that are crucial to understand. These guidelines are set by various governing bodies and are based on extensive research to safeguard against harmful bacteria, viruses, and other hazards.

Key Regulations to Follow

- Temperature Control: Maintain proper temperature ranges for storage, preparation, and service to prevent microbial growth. Cold items should be kept below 41°F (5°C), and hot items should be kept above 135°F (57°C).

- Sanitation Standards: Establish and follow stringent cleaning protocols for equipment, utensils, and surfaces to avoid contamination. This includes regular washing and disinfecting of high-touch areas.

- Employee Hygiene: Employees must wash hands regularly, especially after handling raw products or using the restroom. Wearing appropriate personal protective equipment (PPE) like gloves and aprons is also required.

- Cross-Contamination Prevention: Prevent the transfer of harmful microorganisms by keeping raw and cooked items separate, using dedicated equipment for each, and ensuring proper storage practices.

- Labeling and Expiry Dates: Ensure that all items are properly labeled with preparation dates, expiry dates, and handling instructions to prevent the use of expired or unsafe products.

By staying informed and compliant with these regulations, you can significantly reduce the risk of contamination and ensure the health and safety of everyone involved. Following these critical guidelines is a responsibility that extends beyond legal requirements; it is a fundamental practice in maintaining a safe and trustworthy environment.

How to Maintain Clean Workspaces

Maintaining a clean and organized workspace is essential to preventing contamination and ensuring a safe environment. Proper cleanliness reduces the risk of harmful microorganisms spreading, which could lead to health hazards. Consistent cleaning practices contribute not only to hygiene but also to overall efficiency and productivity in any setting.

To maintain cleanliness, it’s important to implement regular cleaning schedules, use the right cleaning agents, and ensure that all tools and surfaces are properly sanitized. The following guidelines will help establish and maintain a clean, safe environment:

Cleaning and Sanitizing Procedures

- Establish a Regular Cleaning Schedule: Clean work areas frequently throughout the day, especially after each use. This helps to eliminate potential contaminants before they have a chance to spread.

- Use Appropriate Cleaning Agents: Choose the right products for different surfaces and materials. Ensure that cleaning agents are effective at killing bacteria and viruses without causing damage to tools and surfaces.

- Clean Equipment After Each Use: Regularly sanitize tools, utensils, and any equipment used during the preparation or service process. This helps prevent cross-contamination and keeps everything hygienic.

- Proper Waste Disposal: Make sure that trash and waste are regularly removed and disposed of properly to avoid buildup, which can become a breeding ground for bacteria.

Organizing the Workspace

- Keep Tools and Materials Organized: Store tools and materials in designated areas. This prevents clutter and reduces the risk of mixing clean and contaminated items.

- Separate Work Zones: Designate separate areas for tasks that require different levels of cleanliness. For example, separating raw materials from prepared items helps reduce the risk of contamination.

- Ensure Proper Ventilation: Proper airflow in workspaces helps reduce moisture build-up and keeps areas dry, which discourages the growth of harmful microorganisms.

By following these guidelines, you can ensure that the workspace remains clean and hygienic, reducing the risk of contamination and creating a safer environment for everyone involved.

Safe Cooking Temperatures Explained

Understanding the correct temperatures required for cooking various items is essential to ensuring that harmful pathogens are effectively killed, making the meal safe for consumption. Proper cooking temperatures not only prevent the risk of foodborne illnesses but also help preserve the quality and texture of ingredients.

Each type of item has a specific temperature range that must be reached to ensure safety. These temperature guidelines are set to destroy harmful bacteria and viruses that can cause illness. Knowing the safe cooking temperatures for different ingredients is key to maintaining both health standards and culinary excellence.

Recommended Internal Temperatures

- Beef, pork, lamb, and veal (steaks, chops, roasts): Cook to an internal temperature of at least 145°F (63°C), followed by a three-minute rest.

- Ground meats (beef, pork, lamb, veal): Cook to a minimum of 160°F (71°C) to ensure safety.

- Poultry (chicken, turkey, duck): The internal temperature should reach at least 165°F (74°C) to eliminate any harmful bacteria.

- Eggs: Cook eggs until both the yolk and the white are firm. The internal temperature should be 160°F (71°C).

- Seafood (fish, shellfish): Cook fish to an internal temperature of 145°F (63°C) and ensure that it is opaque and flakes easily with a fork.

Why Temperature Matters

- Prevents Illness: Ensuring that the correct temperature is reached is the most effective way to kill harmful bacteria like Salmonella, E. coli, and Listeria.

- Maintains Quality: Cooking at the right temperature helps preserve texture, moisture, and flavor, resulting in a better-tasting dish.

- Avoids Overcooking: Cooking at the recommended temperature helps to prevent overcooking, which can dry out ingredients and degrade their quality.

By following safe cooking temperature guidelines, you can ensure that meals are not only delicious but also safe to eat, providing peace of mind for both the chef and the consumer.

Allergen Management in Food Handling

Effectively managing allergens is crucial in any environment that involves the preparation or service of meals. Cross-contact between allergens and other ingredients can result in severe reactions for individuals with sensitivities. The goal is to implement clear protocols that minimize the risk of allergen exposure, ensuring that consumers are protected from potential harm.

It is essential to identify common allergens and understand the specific steps required to handle them safely. This includes proper storage, preparation, and cleaning methods to prevent cross-contamination. A thorough allergen management plan is necessary for both food establishments and home kitchens to mitigate risks.

Common Allergens to Be Aware Of

| Allergen | Common Sources |

|---|---|

| Peanuts | Peanut butter, snacks, desserts |

| Tree Nuts | Almonds, cashews, walnuts, hazelnuts |

| Milk | Cheese, yogurt, butter, cream |

| Eggs | Mayonnaise, cakes, pasta, sauces |

| Soy | Tofu, soy sauce, processed foods |

| Wheat | Bread, pasta, baked goods |

| Fish | Salmon, tuna, shellfish |

| Shellfish | Crab, shrimp, lobster, oysters |

Effective Allergen Control Measures

- Clear Labeling: Ensure all ingredients are properly labeled, especially in packaged products, to inform consumers of the presence of potential allergens.

- Separate Equipment: Use separate utensils, cutting boards, and cookware when preparing allergen-containing ingredients to prevent cross-contact.

- Training and Awareness: Train staff in allergen identification, safety protocols, and cleaning procedures to prevent accidental exposure.

- Clean Surfaces Thoroughly: Regularly sanitize surfaces, including countertops and utensils, to avoid contamination between different ingredients.

By following these guidelines, individuals and establishments can better manage allergens, ensuring both safety and peace of mind for those with sensitivities. It is essential to integrate these practices into every step of the food preparation process, from ingredient sourcing to serving the final dish.

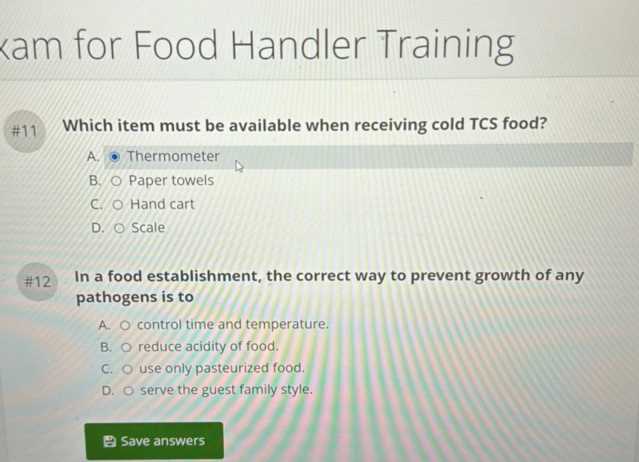

Food Handling Test Question Examples

Understanding the key concepts behind safe practices in meal preparation and service is essential. To help evaluate knowledge and ensure compliance, various questions can be used to test an individual’s understanding of safety protocols. These questions focus on fundamental topics such as cleanliness, proper storage, and the prevention of cross-contamination, all of which are critical for maintaining a safe environment.

Example Questions on Proper Procedures

- What is the recommended temperature for storing perishable items?

- How should equipment be cleaned to prevent contamination from harmful bacteria?

- Which actions should be taken to avoid cross-contact between allergens and other ingredients?

- What is the appropriate procedure for handling raw meat?

- How can you ensure that surfaces are sanitized effectively after preparation?

Example Questions on Personal Safety Practices

- Why is handwashing essential before preparing meals?

- What protective gear should be worn when preparing meals?

- How often should hand sanitizers be used when working in the kitchen?

- What are the signs of a contaminated ingredient or preparation area?

- What actions should you take if you suspect contamination in the kitchen?

These example questions are designed to test knowledge and reinforce the importance of maintaining safety and hygiene throughout the meal preparation process. Mastery of these concepts ensures that individuals can effectively contribute to a safe environment in any food-related setting.

Importance of Food Handling Certifications

Obtaining certifications in proper safety practices is essential for anyone involved in preparing, storing, or serving meals. These qualifications not only demonstrate knowledge of essential hygiene protocols but also ensure a higher standard of health and safety within any establishment. Certifications equip individuals with the skills needed to minimize risks, prevent contamination, and handle ingredients correctly, contributing to a safer environment for both workers and customers.

Why Certifications Are Vital

Certifications in safety practices are crucial for a variety of reasons:

- Legal Compliance: Many jurisdictions require staff to be certified to comply with local regulations and health codes.

- Risk Reduction: By understanding and applying best practices, certified individuals are better equipped to reduce health risks and prevent foodborne illnesses.

- Professional Development: Achieving certification can improve career prospects by enhancing skills and demonstrating professionalism to employers.

- Customer Confidence: Customers are more likely to trust businesses that prioritize safety and hygiene, leading to better reviews and customer loyalty.

How Certifications Contribute to Workplace Safety

In the workplace, certification ensures that employees are knowledgeable in several critical areas:

- Correct temperature control for various products

- Techniques for cleaning and sanitizing equipment

- Identifying and preventing cross-contamination

- Proper storage and disposal methods

Ultimately, certifications are an investment in both personal and organizational health. With ongoing training, certified individuals stay updated on the latest safety standards, ensuring that safety practices evolve with industry advancements.

How to Pass a Food Safety Test

Passing an exam on proper practices in the preparation, storage, and serving of meals requires a clear understanding of essential safety guidelines. This includes recognizing risks, applying hygiene measures, and following established protocols to ensure health standards are met. With the right approach, you can successfully demonstrate your knowledge and secure the necessary certification for working in any related environment.

Here are some tips to help you prepare:

- Review Key Concepts: Focus on the fundamental principles, such as temperature control, cleanliness, cross-contamination prevention, and personal hygiene.

- Understand Local Regulations: Be familiar with the rules and regulations that apply in your region or country, as these may vary depending on location.

- Take Practice Quizzes: Many courses offer sample questions to help you get a feel for the format and types of inquiries you’ll encounter during the exam.

- Study Real-World Scenarios: Think about how safety measures apply to common situations in kitchens and service areas. Being able to apply your knowledge will help you answer situational questions more effectively.

- Stay Calm and Focused: During the exam, carefully read each question and take your time to choose the best answer. Rushed decisions can lead to mistakes.

By thoroughly understanding the material and practicing problem-solving, you will be well-prepared to pass the assessment and ensure that you are ready to contribute to a safe and clean environment in any workplace.