Ensuring proper handling and preparation of items in any industry is crucial for maintaining high standards of hygiene and quality. Understanding the key concepts behind these procedures is necessary to ensure compliance with regulations and promote a healthy environment. This section will guide you through the core principles and provide insights to help you navigate the necessary steps for success in the field.

Throughout the following sections, we will address common challenges faced by professionals and offer useful tips to overcome them. Gaining expertise in these areas is not only about passing assessments but also about enhancing practical skills that contribute to a safer and more efficient workplace.

Mastering these concepts and applying them in real-world scenarios will ensure that you meet the required standards. By focusing on these fundamental areas, you’ll be better prepared to handle various situations effectively and with confidence.

Premier Food Safety Test Answers

In order to excel in certification evaluations related to hygiene and health standards, it’s essential to have a deep understanding of key practices that ensure a safe and clean environment. This section provides valuable insights into the core principles of proper handling and management, focusing on what you need to know to achieve success in industry examinations.

To properly navigate through these evaluations, professionals must familiarize themselves with common scenarios and questions. With practical knowledge and a clear grasp of regulations, individuals can confidently approach the process, knowing they are prepared to meet the highest standards.

The ability to recall and apply the right procedures at the right moment is what differentiates those who succeed in these assessments. Mastering the material not only helps in formal evaluations but also equips individuals with skills that contribute to long-term success and workplace safety.

Understanding Food Safety Testing Basics

At the core of ensuring health and cleanliness in any environment is a strong foundation in essential procedures and protocols. Recognizing the basic principles behind proper management, handling, and quality control is crucial for any professional looking to excel in industry evaluations. This section focuses on the fundamental concepts that form the backbone of regulatory assessments and best practices.

Having a solid understanding of the critical aspects involved–ranging from hygiene protocols to compliance with standards–can make the difference between success and failure in these assessments. Familiarity with key guidelines allows individuals to confidently implement necessary practices and avoid common pitfalls that may arise during evaluations.

Grasping these essentials not only helps in passing assessments but also contributes to creating safer environments in everyday operations. By applying this knowledge, individuals can ensure that they meet the required standards for health and cleanliness across various industries.

Key Steps in Passing the Premier Test

To successfully navigate through any certification assessment, it’s crucial to follow a well-structured approach that emphasizes preparation, understanding, and application of industry standards. Mastering the right steps ensures that individuals are fully equipped to handle questions and scenarios that are commonly presented in these evaluations.

Step 1: Understand Core Concepts

Before attempting any assessment, it’s important to have a comprehensive understanding of the fundamental principles involved. This includes grasping essential guidelines, regulations, and procedures that are integral to the evaluation process. Focus on learning key topics that frequently appear in the assessment, such as proper handling techniques, cleanliness standards, and compliance with health codes.

Step 2: Practice with Real-World Scenarios

Hands-on practice can significantly improve your chances of passing. By simulating real-life situations and applying the knowledge in practical settings, individuals can develop a stronger command of the subject matter. Practicing under timed conditions and reviewing common mistakes will also enhance test-taking abilities.

Step 3: Review Commonly Asked Questions

Reviewing typical questions from past assessments can help familiarize you with the format and expectations. Many certifications contain recurring themes or concepts that are tested in different ways, so understanding these trends will give you an edge when approaching the evaluation.

| Topic | Preparation Tip |

|---|---|

| Proper Handling | Study guidelines for cleanliness and hygiene protocols. |

| Regulations | Familiarize yourself with industry-specific health standards. |

| Common Mistakes | Identify frequent errors and how to avoid them in real scenarios. |

By following these key steps and committing to consistent study and practice, individuals can improve their chances of successfully passing the certification process and becoming proficient in industry-specific standards.

Common Mistakes in Food Safety Tests

When undergoing any evaluation related to health and hygiene standards, it’s common to encounter certain pitfalls that can hinder success. These mistakes are often avoidable with proper preparation and attention to detail. Understanding these common errors and knowing how to avoid them can significantly improve your chances of passing.

Overlooking Key Guidelines

A frequent mistake is not thoroughly understanding or following the primary regulations. Many individuals focus on memorizing facts without truly grasping the importance of the guidelines, leading to misunderstandings during assessments. Taking time to study the core concepts and understanding how they apply in practical scenarios is essential to avoid this error.

Underestimating Practical Application

Another common mistake is neglecting the practical aspect of the evaluation. While theoretical knowledge is important, it’s the ability to apply this knowledge in real-world situations that makes the difference. Hands-on practice and understanding how to implement procedures correctly in a workplace environment are critical for performing well.

By being mindful of these common mistakes and addressing them ahead of time, candidates can approach the evaluation with confidence and a clear understanding of what is expected.

How to Prepare for Food Safety Exams

Preparing for an industry certification requires more than just studying theory; it involves developing a deep understanding of essential procedures and applying this knowledge effectively. Proper preparation is key to success, and focusing on both the theoretical and practical aspects can make all the difference in passing the assessment.

One of the first steps is familiarizing yourself with the core topics that will be covered. These include key regulations, industry standards, and best practices. Knowing what to expect and understanding the format of the evaluation will help you feel more confident during the process.

Additionally, hands-on practice and real-life simulations are crucial. They help you apply what you’ve learned and prepare for practical questions and scenarios that may arise during the evaluation.

| Preparation Step | Tip for Success |

|---|---|

| Study Regulations | Review official guidelines and compliance requirements thoroughly. |

| Hands-on Practice | Simulate real-life scenarios to test your skills in action. |

| Familiarize with Question Formats | Practice answering common questions and scenarios found in previous evaluations. |

By following these preparation steps and committing to thorough study and practice, you will be better equipped to navigate the certification process and succeed in your evaluation.

Top Tips for Food Safety Knowledge

Mastering the essential principles of health and cleanliness is crucial for anyone aiming to work in industries where these standards are paramount. Gaining in-depth knowledge and understanding how to apply this information correctly can significantly improve your performance in both theoretical and practical evaluations. This section provides practical tips to help you build a solid foundation and advance your understanding of key procedures.

Tip 1: Focus on Core Principles

Begin by familiarizing yourself with the fundamental concepts that govern hygiene and regulatory standards. A clear understanding of core guidelines will ensure you have a strong base to tackle more complex topics. Review critical areas such as handling techniques, personal hygiene, and infection control, as they are frequently tested in assessments.

Tip 2: Keep Up with Industry Changes

Staying informed about changes in industry regulations and health standards is crucial. Updates to best practices and legal requirements can have a significant impact on evaluations. Regularly review new information, attend seminars, and keep an eye on industry news to ensure you’re always up-to-date.

| Tip | Action |

|---|---|

| Understand Key Guidelines | Study hygiene protocols, personal health standards, and legal compliance. |

| Stay Updated | Follow industry news and review updated regulations regularly. |

| Practical Experience | Practice applying concepts in real-world environments to reinforce knowledge. |

By following these essential tips, you’ll enhance your knowledge and become better equipped to meet industry standards, ultimately ensuring success in both evaluations and practical applications.

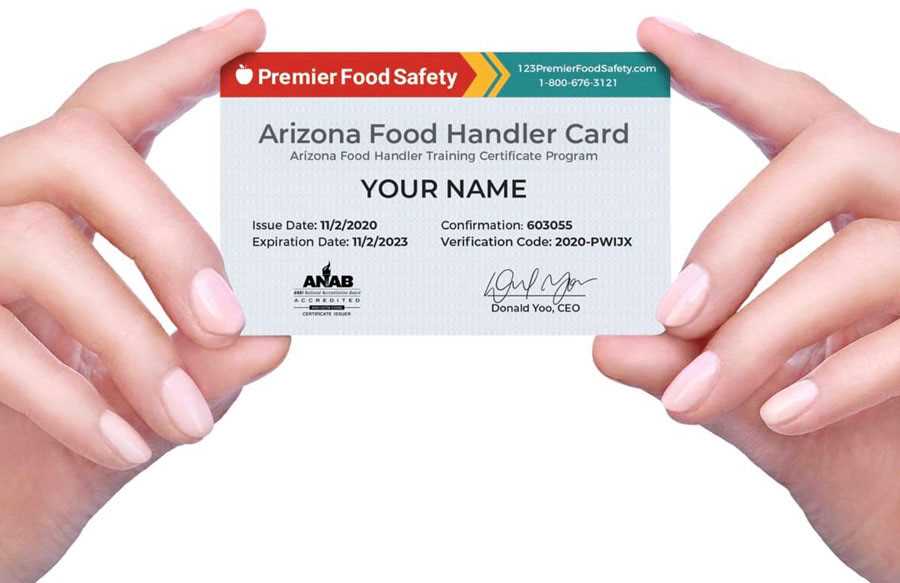

Importance of Food Handling Certifications

Obtaining certification in proper handling techniques is a vital step for professionals working in industries where hygiene and health standards are paramount. These credentials not only validate an individual’s knowledge but also demonstrate a commitment to maintaining the highest standards in the workplace. A certified individual is better equipped to follow regulations, avoid common mistakes, and contribute to a safer environment for both staff and customers.

Beyond compliance, certifications help boost credibility and can lead to greater career opportunities. In many cases, employers seek certified professionals to ensure their operations meet legal requirements and industry expectations. Being certified reflects competence and dedication, qualities that are valued in any workplace.

Furthermore, these certifications are often required to pass inspections, qualify for certain positions, or meet local and national regulations. Without them, businesses may face penalties or legal issues. Achieving certification ensures that individuals are well-prepared to handle complex situations and comply with necessary guidelines.

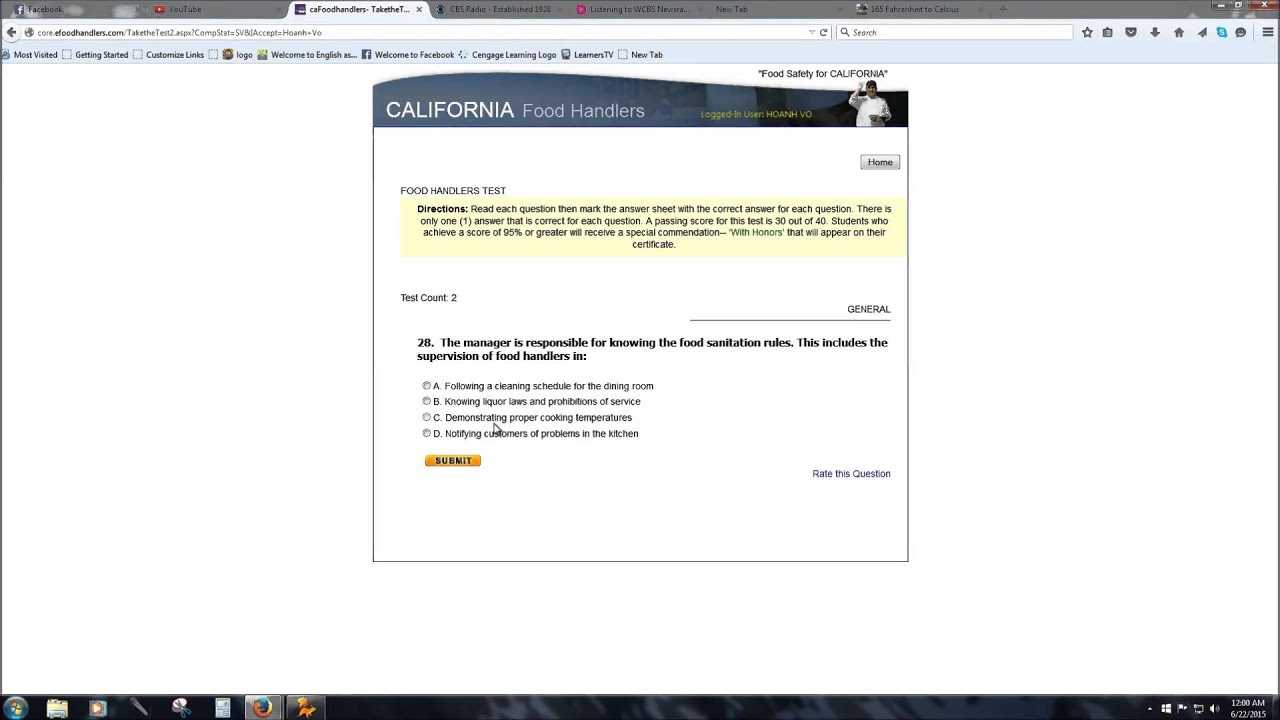

What to Expect in Food Safety Tests

When preparing for an assessment related to health and hygiene regulations, it’s essential to understand what will be evaluated and how the process is structured. These evaluations often test both theoretical knowledge and practical application, assessing your ability to follow guidelines and implement procedures effectively. Understanding the format and key focus areas can help you feel more confident and prepared when it’s time to take the evaluation.

Types of Questions You May Encounter

These assessments generally consist of a variety of question types, designed to test your understanding and practical skills. Here are some of the most common question formats:

- Multiple Choice: Questions with several options, where you must choose the correct one.

- True/False: Statements that you must identify as correct or incorrect based on your knowledge of regulations.

- Scenario-based: Questions where you’re presented with a real-life situation and must determine the appropriate actions.

Key Areas of Focus

The evaluation will typically focus on critical aspects of maintaining cleanliness and adhering to health standards. Below are the main topics you should expect:

- Proper handling and storage of materials

- Personal hygiene practices and protocols

- Risk management and how to address potential hazards

- Compliance with industry regulations and legal requirements

- Sanitation procedures and cleanliness maintenance

Being aware of these key areas will allow you to concentrate your studies on the most relevant topics and increase your chances of success.

Food Safety Guidelines for Industry Workers

Maintaining high standards of hygiene and cleanliness is essential for those working in environments where public health is a priority. Adhering to the best practices not only ensures compliance with regulations but also plays a critical role in preventing contamination and ensuring a safe environment. Below are some fundamental guidelines that every industry worker should follow to promote well-being and safety within their workplace.

Essential Hygiene Practices

Workers must take personal hygiene seriously to prevent the spread of harmful microorganisms. Here are key hygiene practices to follow:

- Hand Washing: Wash hands thoroughly with soap and water before handling any materials, especially after using the restroom or touching potentially contaminated surfaces.

- Proper Clothing: Always wear clean uniforms or protective clothing and ensure hair is tied back, using hairnets or caps as required.

- Use of Gloves: Wear gloves when handling items that may come into contact with contaminants, and ensure they are changed regularly.

- Avoiding Cross-Contamination: Keep raw materials separate from ready-to-eat products to avoid cross-contamination.

Best Practices for Handling Materials

Proper handling of materials is crucial to prevent contamination and ensure compliance with industry standards. Workers should focus on these key actions:

- Temperature Control: Ensure that all items are stored at the correct temperature to prevent spoilage or bacterial growth.

- Regular Cleaning: Clean workstations, tools, and equipment frequently, using appropriate cleaning agents and sanitizing solutions.

- Safe Waste Disposal: Dispose of waste materials in a manner that prevents contamination and keeps the environment clean.

By following these guidelines, industry workers can contribute to a safe and clean environment, reducing risks and ensuring that standards are consistently met.

Essential Knowledge for Food Safety Compliance

To work in environments where health and hygiene standards are strictly enforced, it’s crucial to have a solid understanding of the regulations and practices that help prevent contamination and promote safety. Having a deep knowledge of key guidelines ensures that workers can operate in compliance with legal and industry standards, minimizing risks and contributing to a safe and healthy environment. This section outlines the essential areas of knowledge that industry professionals should possess to meet compliance requirements effectively.

Key Regulatory Standards

Compliance with regulatory standards is a fundamental aspect of any workplace that handles consumables. Workers must be familiar with local, national, and international regulations governing hygiene, contamination prevention, and product safety. Key regulations include:

- HACCP (Hazard Analysis and Critical Control Points): A systematic approach to identifying and managing potential hazards in the production process.

- FDA Guidelines: The Food and Drug Administration sets forth requirements for food handling, packaging, and storage.

- Local Health Codes: Local authorities may have specific rules and protocols regarding cleanliness and sanitation that must be followed.

Best Practices for Hygiene and Contamination Control

Knowledge of best practices is equally important for maintaining safety and hygiene standards. Here are some of the best practices that workers should adopt:

- Proper Hand Washing: Regular and thorough hand washing is essential to prevent the transfer of bacteria and viruses.

- Temperature Management: Maintaining proper temperatures for storage and preparation is critical to prevent spoilage and bacterial growth.

- Cross-Contamination Prevention: Keeping raw and ready-to-eat items separate is a crucial practice for ensuring safety.

By mastering these critical areas of knowledge, workers can significantly reduce the risk of contamination and ensure compliance with industry standards, helping to maintain a safe and healthy environment for all involved.

Common Food Safety Test Questions Explained

When preparing for assessments in hygiene and health practices, it’s essential to familiarize yourself with the types of questions that are often asked. These questions are designed to evaluate your understanding of proper procedures, regulations, and best practices in maintaining a clean and safe environment. In this section, we will explore some of the most common questions you may encounter and provide clear explanations to help you prepare effectively.

Understanding Basic Hygiene Practices

One of the most frequently asked question categories revolves around hygiene practices. These questions typically address how to properly handle materials, maintain cleanliness, and reduce risks of contamination. Here are some examples:

- What is the correct way to wash hands? Proper handwashing involves scrubbing with soap and water for at least 20 seconds, ensuring all areas are cleaned, including nails and wrists.

- Why is it important to separate raw and cooked items? Separating raw materials from ready-to-eat items prevents cross-contamination, which could lead to foodborne illnesses.

- When should gloves be changed? Gloves should be changed after handling raw materials, using the restroom, or touching contaminated surfaces.

Managing Temperature and Storage

Temperature control and storage are critical topics that are often tested. These questions evaluate your knowledge on how to store and maintain the proper temperature for various items to prevent spoilage and bacteria growth:

- What is the danger zone for temperature? The danger zone is between 40°F (4°C) and 140°F (60°C), where bacteria grow most rapidly. It’s essential to keep perishable items outside of this range.

- How should refrigerated items be stored? Perishable items should be stored at or below 40°F (4°C), and raw materials should be kept separate from cooked or ready-to-eat products.

- Why is temperature monitoring necessary? Consistent temperature checks ensure that items are stored and prepared at safe levels to prevent contamination and spoilage.

By understanding these common questions and their answers, you will be better prepared to demonstrate your knowledge and pass assessments in maintaining a safe and hygienic environment.

How to Improve Food Safety Skills

Improving hygiene and handling practices is a continuous process that requires dedication, awareness, and a commitment to learning. Developing stronger skills in maintaining a clean, safe, and compliant environment benefits not only the individuals involved but also contributes to the overall well-being of the community. This section will explore several strategies to enhance your abilities in maintaining standards for cleanliness, contamination control, and proper handling procedures.

Continuous Education and Training

One of the most effective ways to improve your abilities is through ongoing education and training. This ensures that you stay up to date with the latest guidelines, technologies, and best practices. Consider the following approaches:

- Participate in Workshops: Attending hands-on workshops can provide practical knowledge and insight into real-world scenarios, reinforcing what you’ve learned.

- Take Online Courses: Many organizations offer online certifications and courses that focus on essential hygiene and handling techniques, often with tests to gauge progress.

- Stay Informed on Regulations: Health regulations and protocols can evolve over time. Regularly reviewing official updates helps ensure compliance with the latest requirements.

Practice and Reinforcement in the Workplace

To solidify your skills, it is essential to practice what you’ve learned in a professional setting. Implementing protocols daily, receiving feedback from supervisors, and participating in team discussions can enhance your proficiency. Key practices include:

- Regular Self-Assessments: Periodically evaluate your practices to identify areas where improvement is needed. Conducting self-checks or seeking peer reviews helps recognize gaps in knowledge.

- Implement Standard Operating Procedures (SOPs): Familiarize yourself with the company’s SOPs and make sure to follow them consistently to ensure safe practices are maintained across all processes.

- Seek Mentorship: Learning from more experienced colleagues can provide valuable insights and allow you to gain practical knowledge that textbooks or courses might not cover.

By focusing on education, continuous practice, and leveraging available resources, you can significantly improve your handling practices and contribute to a safer and more hygienic environment in your workplace.

Food Safety Test Results and What They Mean

Upon completing an assessment focused on health protocols and proper handling procedures, the results offer valuable insights into an individual’s performance. These outcomes help gauge one’s ability to maintain clean and hygienic practices in their work environment. In this section, we will break down what various scores indicate and how they can guide improvements.

Understanding the Different Outcomes

Typically, assessments will categorize results into different classifications such as “pass,” “fail,” or “requires attention.” Each result reflects how well the individual adhered to key guidelines and practices. Here’s a closer look at each category:

- Pass: A “pass” indicates that the individual has met the necessary standards and has demonstrated sufficient knowledge of proper procedures. The result signifies that essential practices were followed correctly.

- Fail: A “fail” means that significant errors were made during the evaluation, possibly affecting safety or hygiene. This outcome suggests the need for additional training or immediate corrective measures.

- Requires Attention: This result signals that certain areas of practice need improvement. While the individual may have shown understanding overall, specific procedures or practices require further attention to ensure full compliance.

Next Steps After Receiving Your Results

Once you understand the meaning behind your results, it’s important to take appropriate action based on your outcome. Here are some steps you can take:

- If You Pass: Celebrate your success, but continue to enhance your knowledge and skills. Stay up-to-date with the latest practices and protocols to maintain your high standards.

- If You Fail: Analyze where mistakes were made and focus on those areas. Consider retaking the course, attending refresher workshops, or reviewing the guidelines for best practices.

- If You Need Improvement: Review the areas that need attention. Focus on refining specific skills and seek additional training or support to address these gaps effectively.

Understanding and interpreting your assessment results correctly will help you make necessary adjustments and continue improving your practices, ensuring a safer environment for everyone involved.

Best Resources for Food Safety Learning

Acquiring expertise in handling health protocols and maintaining hygiene standards is crucial for anyone involved in managing or preparing products. Fortunately, there are numerous resources available to enhance your knowledge and skills in these areas. Whether you’re a beginner or looking to refresh your expertise, the following tools and platforms offer invaluable learning opportunities.

Top Learning Platforms

Several online platforms provide courses and certifications tailored to improving your understanding of hygiene practices. These platforms often feature expert-led content, quizzes, and downloadable materials for hands-on learning.

- Coursera: Offers a variety of courses in partnership with leading universities, providing comprehensive learning on health protocols, including certifications upon completion.

- edX: Another excellent platform featuring courses from reputable institutions, ideal for anyone wanting to learn about cleanliness procedures, regulations, and compliance.

- Udemy: Known for its practical courses, Udemy provides affordable learning modules focused on best practices in handling and hygiene.

Books and Guides

Books remain a valuable resource for understanding the fundamentals and more advanced concepts of proper handling practices. Below are some highly regarded titles:

- The Food Handler’s Handbook: A comprehensive guide that covers basic protocols for maintaining hygiene and preventing contamination.

- Safe Food Handling Guide: This book provides a detailed approach to developing and maintaining effective health protocols in a variety of settings.

- The Essentials of Food Hygiene: Focuses on the scientific principles behind effective hygiene, offering deep insights into foodborne illnesses and prevention methods.

Professional Organizations

Various professional bodies offer access to seminars, workshops, and certification programs. Engaging with these organizations can provide ongoing education and networking opportunities.

- National Restaurant Association (NRA): Offers certification programs like the ServSafe program, which covers all aspects of health protocols in foodservice.

- Food Safety Magazine: This publication provides industry insights, research articles, and case studies focused on best practices in maintaining sanitary conditions.

- International Food Protection Training Institute (IFPTI): Provides accredited training programs for industry professionals looking to stay compliant with global health standards.

These resources are essential for anyone striving to master essential practices for cleanliness, hygiene, and regulatory compliance. Whether you choose online learning, professional books, or certification programs, consistent education will ensure you stay ahead in a field that’s constantly evolving.

Challenges in Food Safety Testing

Ensuring that products meet health standards involves overcoming numerous obstacles, from maintaining consistent procedures to interpreting complex regulations. As industries strive to maintain high hygiene and handling standards, various challenges can arise. Understanding these issues is crucial for improving the effectiveness of practices and achieving compliance.

Common Obstacles in Implementing Protocols

One of the biggest hurdles in ensuring compliance with health regulations is the complexity of maintaining proper procedures across all stages of production. Here are some common challenges faced by industries:

- Inconsistent Procedures: Ensuring uniformity in procedures, especially in large-scale operations, can be difficult, leading to potential gaps in hygiene practices.

- Lack of Training: Inadequate or inconsistent training for workers often leads to errors in maintaining cleanliness, contaminating products, or mishandling sensitive materials.

- Inadequate Resources: Some industries face shortages of necessary equipment or personnel, which can hinder their ability to properly implement hygiene protocols and prevent contamination.

Complex Regulations and Compliance Issues

Another challenge involves navigating the vast array of regulations and standards that vary across countries and industries. These requirements can be complex and constantly evolving. Companies must stay updated and ensure all employees adhere to the latest guidelines.

- Confusing Guidelines: Different regions may have varying regulations, making it difficult for businesses to understand and implement the appropriate measures.

- Frequent Audits and Inspections: Routine checks and inspections can be burdensome for businesses, especially when dealing with large operations or remote locations.

- Legal and Financial Implications: Non-compliance can result in hefty fines, lawsuits, or reputational damage, making it crucial to stay aligned with evolving health standards.

While these challenges present obstacles, they also offer opportunities for businesses to improve processes and adapt. By investing in better resources, continuous training, and staying informed on the latest industry regulations, industries can reduce risks and improve their practices significantly.

Staying Updated on Food Safety Standards

Maintaining compliance with health regulations requires continuous vigilance and adaptation. As industries evolve and new research emerges, standards related to hygiene and handling practices are regularly updated. For professionals in relevant fields, staying informed about these changes is crucial to ensuring the highest levels of quality and public health protection.

One of the key aspects of staying current is understanding the sources where updates are most likely to come from. Regulatory bodies, industry associations, and research institutions often release new guidelines, protocols, and findings that directly impact operational procedures. It is important to actively engage with these sources to avoid falling behind.

Key Resources for Keeping Informed

There are several ways professionals can keep themselves updated:

- Government Publications: Many local and national agencies provide updates on health regulations through official websites, newsletters, and publications.

- Industry Seminars and Conferences: Attending events and conferences allows workers to learn about the latest changes in standards from experts in the field.

- Training Programs: Ongoing education through workshops, online courses, and certification programs ensures workers stay well-informed about evolving standards.

Maintaining a Continuous Learning Culture

Adopting a culture of continuous learning within an organization helps ensure that all team members are aware of the latest changes and can implement new practices efficiently. This approach not only fosters better compliance but also helps mitigate risks associated with outdated practices.

- Regular Internal Reviews: Frequent internal audits and reviews of current procedures help identify areas that may need updating or improvement.

- Encouraging Employee Engagement: Encouraging employees to participate in training and providing them with the tools to stay informed creates a more knowledgeable workforce.

By proactively staying updated on industry standards, organizations can safeguard their operations against risks and ensure compliance with the latest health protocols. This not only ensures better public health outcomes but also strengthens the credibility and reputation of the business.