Ensuring the safety of products prepared and served in any establishment requires a solid understanding of best practices. Whether you are responsible for preparing meals or maintaining a clean environment, grasping key principles is vital to avoid contamination and safeguard public health.

Comprehending hygiene practices, proper storage techniques, and recognizing health hazards are fundamental to providing safe experiences for consumers. Every worker must be familiar with the necessary protocols that help prevent illness or accidents related to improper management of ingredients and tools.

In this guide, we will address the core knowledge needed to successfully navigate tests and assessments designed for workers involved in handling consumables. The insights shared will equip you with the expertise to pass evaluations and apply safe practices consistently in your role.

360 Training Food Handlers Answers Overview

Mastering the key elements of safe practices in the workplace is essential for anyone involved in the preparation or handling of consumables. This section provides a detailed overview of the essential concepts and knowledge required to pass the certification assessment. Focusing on the principles of hygiene, safety protocols, and risk prevention, it highlights the core areas tested in evaluations.

Core Knowledge Areas for Success

To successfully navigate assessments, it’s crucial to understand the fundamentals of sanitation, temperature control, and safe ingredient handling. These topics cover everything from recognizing potential contamination risks to applying best practices for storage and personal cleanliness. Each section prepares individuals to handle various challenges they may encounter on the job.

How to Approach the Certification Exam

When preparing for the certification exam, it’s important to focus on both theoretical knowledge and practical application. Practicing common scenarios and reviewing sample questions can help build confidence and reinforce critical concepts. A thorough understanding of safety regulations and their real-world applications is key to ensuring compliance and passing the assessment with ease.

Understanding Food Safety Certification Requirements

Obtaining certification in safe practices is a crucial step for anyone working with consumables. It ensures that workers are knowledgeable about the procedures and standards necessary to maintain a hygienic and secure environment. Certification helps prevent contamination, reduces health risks, and ensures compliance with local regulations.

To earn certification, individuals must demonstrate proficiency in various essential areas, such as sanitation, handling protocols, and risk management. The requirements often include passing written assessments that test theoretical knowledge and sometimes practical evaluations that confirm the ability to apply these principles in real-world settings.

Meeting these requirements not only guarantees that workers are equipped with the right skills but also enhances public trust in the safety of prepared products. As such, understanding the specific criteria and preparing thoroughly is essential to successfully completing the certification process.

Key Concepts in Food Handling Training

In any workplace where consumables are prepared or served, understanding the core principles of safety and hygiene is vital. There are several key concepts that everyone involved in these activities should be familiar with to ensure a secure and healthy environment. These principles cover a range of practices, from contamination prevention to the proper management of ingredients and tools.

Some of the most critical topics in this field include sanitation, temperature control, and the correct use of equipment. Mastering these concepts not only helps prevent illnesses but also ensures compliance with regulations designed to protect both consumers and workers.

| Key Concept | Description |

|---|---|

| Sanitation | Maintaining clean environments and proper hygiene practices to prevent contamination. |

| Temperature Control | Ensuring that ingredients and prepared items are stored and cooked at the correct temperatures to avoid foodborne pathogens. |

| Cross-Contamination | Preventing the transfer of harmful microorganisms from one surface or item to another, especially between raw and ready-to-eat foods. |

| Personal Hygiene | Ensuring that workers maintain cleanliness through proper handwashing and wearing suitable clothing to reduce contamination risks. |

| Proper Storage | Correctly storing ingredients and products to prevent spoilage and contamination, including the use of appropriate storage containers. |

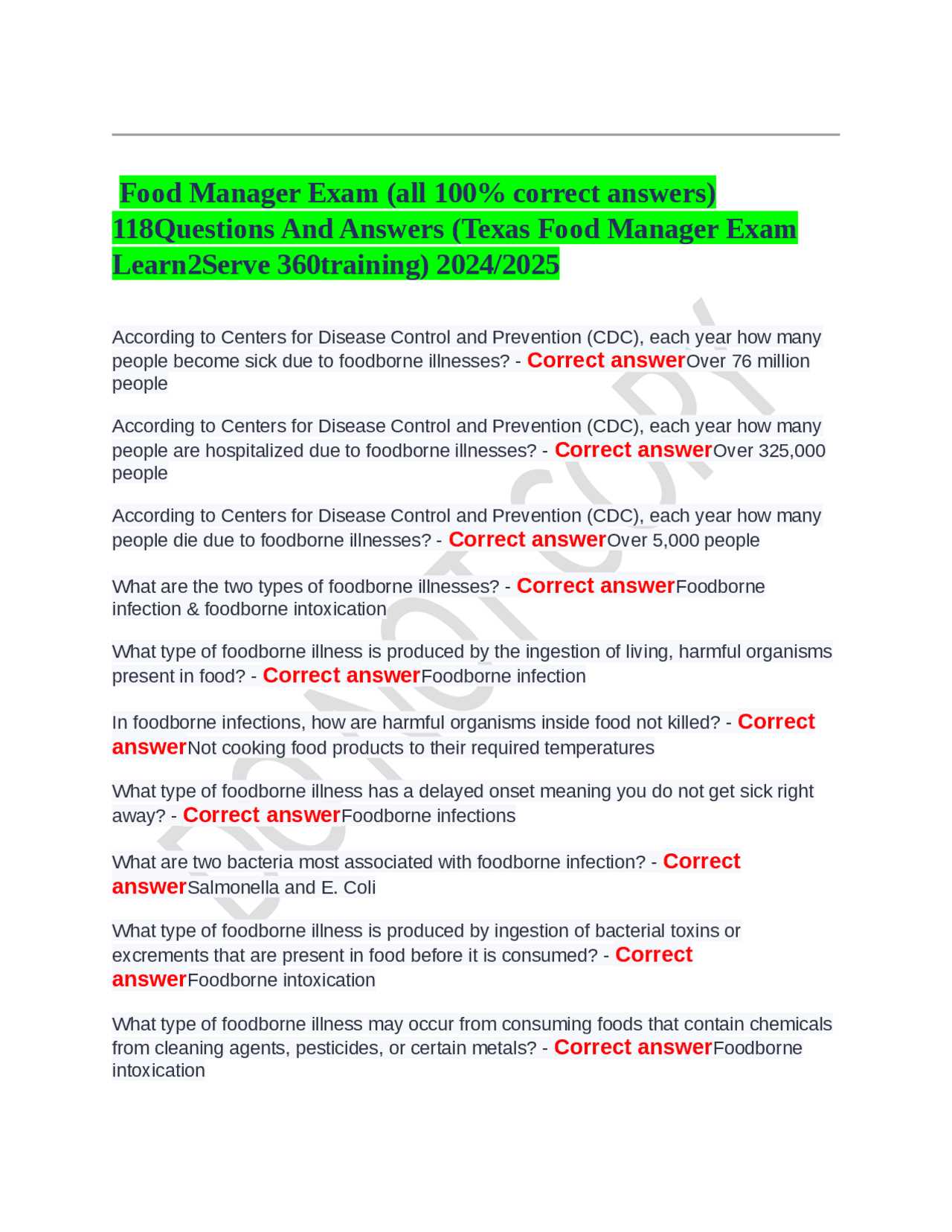

Common Questions in Food Safety Certification Tests

When preparing for an evaluation in safe practices, many candidates encounter similar types of questions designed to assess their understanding of essential concepts. These questions often cover topics related to hygiene, risk prevention, and handling protocols. Knowing the typical areas that will be tested can significantly improve confidence and performance during the assessment.

Typical Topics Covered

Questions on assessments commonly revolve around several core topics. Here are some of the key areas you can expect to encounter:

- Proper handwashing techniques

- Correct storage of perishable items

- Methods for preventing cross-contamination

- Temperature requirements for safe cooking and refrigeration

- Signs of foodborne illnesses and prevention methods

Types of Question Formats

In most evaluations, questions can come in a variety of formats, each testing different aspects of knowledge. These formats include:

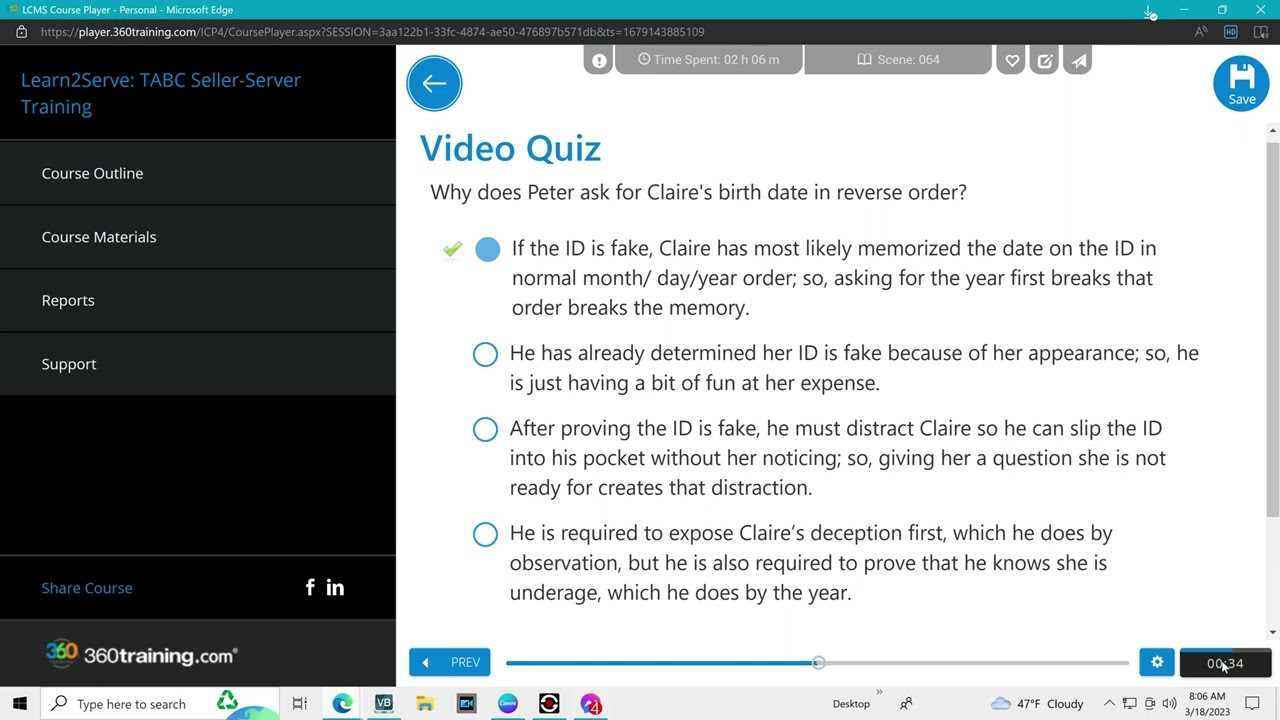

- Multiple choice questions assessing theoretical knowledge

- Scenario-based questions requiring the application of principles in real-world situations

- True/false questions designed to test understanding of safety regulations

Being familiar with these common question types and topics will help you better prepare for the certification process and ensure that you are ready to demonstrate your competence in maintaining safe practices.

How to Pass the Food Safety Exam

Successfully passing the certification exam requires more than just theoretical knowledge. It involves understanding practical applications of safe practices in everyday situations. To ensure a passing score, it’s essential to be well-prepared in both core principles and specific procedures.

Steps to Ensure Success

Follow these key steps to maximize your chances of passing:

- Review Key Concepts: Focus on hygiene, contamination prevention, and temperature control.

- Take Practice Tests: Familiarize yourself with the format and question types to reduce test anxiety.

- Understand Real-World Scenarios: Be ready to apply your knowledge to common workplace situations.

- Study Safety Regulations: Ensure you’re familiar with local laws and health codes.

- Plan Your Time: Allocate enough time for study sessions and practice quizzes.

Test-Taking Tips

On the day of the exam, remember these tips to perform your best:

- Read Questions Carefully: Pay attention to keywords in the question to understand exactly what’s being asked.

- Eliminate Wrong Answers: In multiple-choice questions, eliminate obviously incorrect options to increase your chances of selecting the right one.

- Stay Calm: Focus on the task at hand and take deep breaths if you feel anxious.

- Review Your Answers: If time allows, double-check your responses to ensure accuracy.

By following these strategies, you can confidently approach your certification exam and increase the likelihood of achieving a successful outcome.

Why Food Safety Training is Important

Ensuring the safety of what we eat is essential for protecting public health and preventing illness. Properly educating individuals on safe practices in the handling, preparation, and storage of ingredients is critical to minimizing risks. Without sufficient knowledge, food can easily become a vehicle for harmful bacteria and pathogens that can lead to serious health issues.

Effective education not only reduces the likelihood of contamination but also helps establish standardized procedures that are universally understood and followed. By promoting awareness of hygiene, temperature control, and proper handling techniques, individuals are better equipped to maintain a safe environment and avoid common mistakes that could compromise food quality and safety.

In industries where consumables are prepared and served, this knowledge is not optional–it is a requirement to ensure compliance with health regulations and build trust with consumers. For businesses, it can also prevent costly fines, legal issues, and damage to reputation, all while fostering a culture of safety and responsibility within the workforce.

Common Mistakes in Food Handler Exams

When taking assessments related to safe practices in the workplace, it’s easy to make mistakes that can lead to incorrect answers or missed points. Many candidates overlook key details, misinterpret questions, or fail to apply their knowledge in practical scenarios. Understanding the most common errors can help you avoid these pitfalls and improve your chances of success.

Here are some frequent mistakes that occur during food safety evaluations:

| Mistake | Explanation |

|---|---|

| Skipping Key Details | Not paying attention to small but important details in questions can lead to incorrect answers. |

| Misunderstanding Terminology | Confusing safety terms or regulatory requirements may result in incorrect responses, especially with technical language. |

| Overlooking Practical Scenarios | Focusing too much on theoretical questions and neglecting real-world situations where principles are applied can lead to errors. |

| Not Reviewing Key Concepts | Failing to thoroughly study critical areas like temperature control, cross-contamination, and sanitation can negatively impact exam results. |

| Ignoring Safety Regulations | Not fully understanding local laws or regulations about food safety can result in wrong answers on related questions. |

Avoiding these mistakes is key to performing well. By being mindful of common errors and focusing on understanding both theoretical and practical aspects, you’ll be better prepared for the exam and its challenges.

Food Safety Principles for Handlers

Maintaining a hygienic environment and practicing safe methods is essential for anyone working with consumables. Adhering to safety principles ensures that products remain free from contamination and harmful bacteria, thereby protecting the health of consumers. These principles are grounded in science and are critical in preventing foodborne illnesses.

The core principles for safe practices involve a few fundamental areas that everyone should be well-versed in. These include cleanliness, temperature control, and the correct handling of materials to prevent cross-contamination. Understanding and applying these concepts consistently is crucial for maintaining safety throughout the food preparation process.

Key Principles to Follow

- Cleanliness and Hygiene: Regular handwashing and keeping work areas sanitized are essential to prevent the spread of harmful microorganisms.

- Temperature Control: Always store and prepare ingredients at the right temperatures to prevent bacterial growth. Both hot and cold items should be kept at safe levels.

- Cross-Contamination Prevention: Use separate utensils, cutting boards, and surfaces for raw and cooked products to avoid contaminating ready-to-eat items.

- Proper Handling of Equipment: Ensure that all tools and machines used for preparation are clean, in good condition, and stored properly to avoid contamination risks.

- Food Storage: Store products in airtight containers, and ensure proper labeling and rotation to prevent spoilage and contamination.

Why These Principles Matter

These principles are not just guidelines–they are necessary practices for safeguarding public health. By adhering to them, workers contribute to a safer environment and prevent risks that could lead to foodborne illnesses. Implementing these principles reduces the likelihood of contamination and ensures products are safe for consumers.

Essential Topics Covered in Safety Certifications

To ensure a high level of knowledge and competence in maintaining a hygienic and safe environment, certification programs cover a variety of key topics. These areas are designed to equip individuals with the essential skills and understanding needed to work safely in environments where consumables are handled, prepared, and served. Mastery of these concepts is critical to preventing health risks and ensuring compliance with industry standards.

The following table outlines some of the essential topics that are typically covered in these certification programs:

| Topic | Description |

|---|---|

| Personal Hygiene | Proper handwashing, cleanliness, and the importance of maintaining personal hygiene to prevent contamination. |

| Temperature Control | Understanding the correct temperatures for storing, cooking, and holding ingredients to reduce bacterial growth. |

| Cross-Contamination Prevention | Techniques to avoid transferring harmful microorganisms from raw to cooked products, including the proper use of separate equipment. |

| Safe Storage Practices | Best practices for storing ingredients, including refrigeration, labeling, and rotating stock to maintain freshness and safety. |

| Sanitation Procedures | Cleaning and sanitizing methods for surfaces, equipment, and tools to reduce the risk of contamination. |

| Allergen Awareness | Identifying common allergens and understanding procedures for preventing cross-contact and providing safe food options for sensitive consumers. |

These essential topics form the foundation of any comprehensive program designed to ensure safe practices in environments where consumables are prepared. Gaining proficiency in these areas helps individuals perform their roles effectively while protecting consumer health and complying with safety regulations.

How to Prepare for Safety Questions

Preparing for assessments related to proper practices in handling consumables requires a solid understanding of the core principles that ensure a safe environment. The ability to apply safety standards, follow correct hygiene protocols, and recognize potential hazards is key to performing well on evaluations. Thorough preparation involves reviewing guidelines, understanding the main topics, and practicing with sample questions to build confidence and knowledge.

Understand the Key Concepts

Start by focusing on the fundamental principles of hygiene, temperature control, and safe handling procedures. The more you familiarize yourself with these concepts, the better equipped you will be to answer practical and theoretical questions. Make sure to understand how these concepts relate to the specific tasks you will be performing in real-world scenarios.

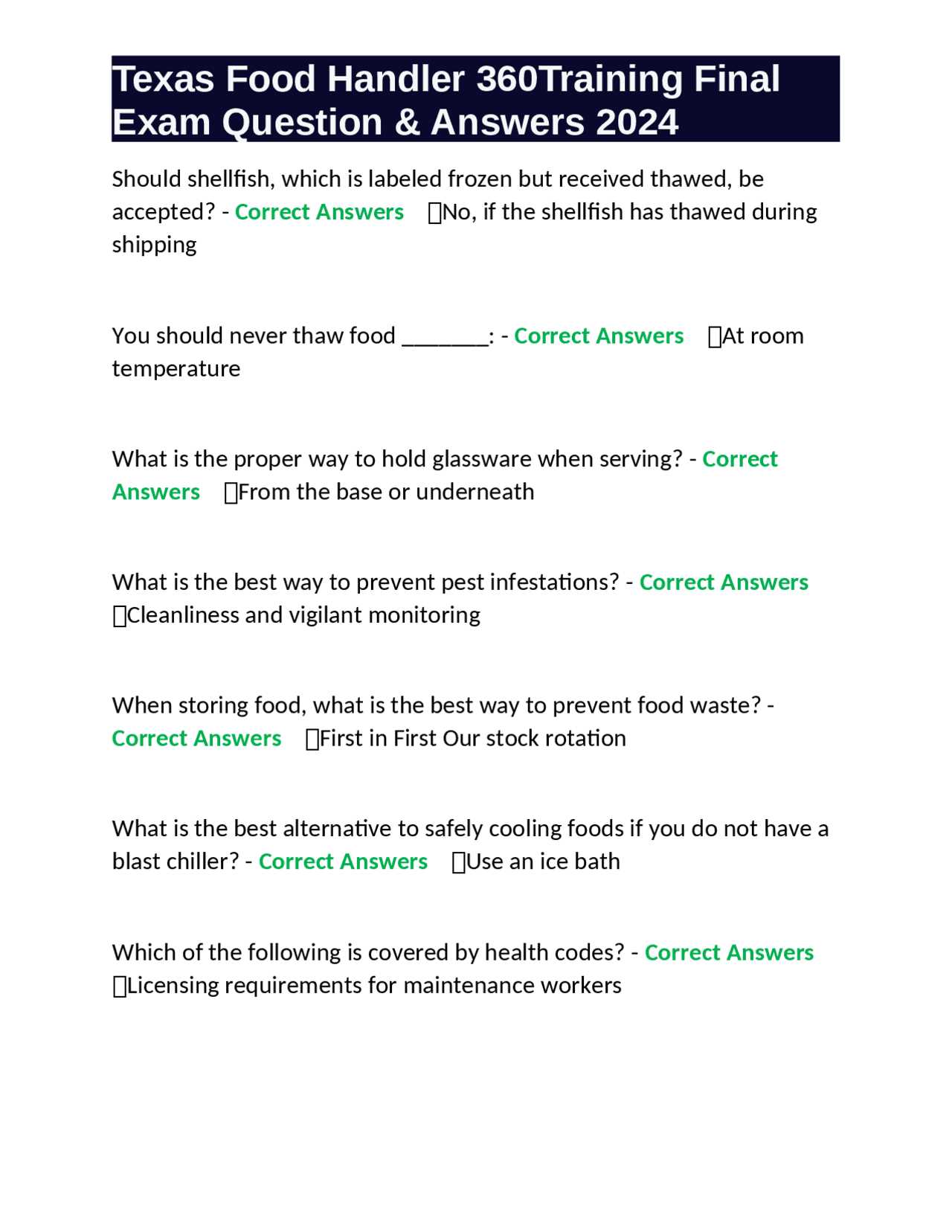

Practice with Sample Questions

One of the best ways to prepare is by practicing with sample questions or quizzes. This allows you to familiarize yourself with the question format, identify areas where you might need more study, and get comfortable answering quickly and accurately. It’s essential to review both correct and incorrect responses to understand why certain answers are right and others are not.

Additionally, using study guides and taking mock tests can help you gauge your readiness and identify areas where further study might be needed. The more practice you have, the easier it will be to handle the pressure of the actual assessment.

Understanding Contamination Risks

Recognizing the various sources of contamination is essential for anyone working in environments where consumables are prepared or served. Contamination can occur in several forms, including biological, chemical, and physical hazards, and understanding these risks is critical to maintaining a safe and hygienic workspace. Preventing contamination starts with awareness and proper handling techniques to minimize exposure to harmful substances.

Contamination risks are often associated with improper practices, such as failing to wash hands properly, storing items at unsafe temperatures, or cross-contaminating different materials. Understanding the specific risks and how they spread can help workers take proactive steps to avoid dangerous situations and protect the well-being of consumers.

Being able to identify potential contamination risks allows workers to implement effective control measures, ensuring a safer environment for everyone involved. Regular training and adherence to safety protocols are essential for minimizing these risks in any environment where consumables are handled.

Correct Handling of Raw Foods

Properly managing raw ingredients is a fundamental aspect of maintaining a safe and hygienic environment. Raw items, particularly those that are perishable, can be breeding grounds for harmful microorganisms if not handled correctly. Ensuring that these items are prepared and stored in a safe manner is critical to preventing contamination and ensuring consumer health.

When dealing with raw materials, there are several key practices to follow:

- Proper Storage: Always store raw items at appropriate temperatures. This helps to slow bacterial growth and ensures that they remain safe for use.

- Separation: Keep raw products separate from ready-to-eat items. This prevents cross-contamination and reduces the risk of harmful bacteria transferring between ingredients.

- Thawing: Thaw raw items in the refrigerator or under cold running water, not at room temperature. Thawing at unsafe temperatures can promote bacterial growth.

- Handling Equipment: Use separate utensils, cutting boards, and surfaces for raw items to avoid cross-contamination. Clean all tools thoroughly before and after use.

- Hygiene: Wash hands thoroughly before and after handling raw items to prevent the spread of harmful germs.

By following these basic guidelines, workers can significantly reduce the risks associated with raw ingredient handling, ensuring a safer environment for food preparation and serving.

Safety Practices for Workers in Food Environments

Ensuring safety in environments where consumables are prepared or served is essential for maintaining the well-being of both workers and customers. Adhering to proper safety practices helps prevent contamination, reduces the risk of illness, and creates a clean and hygienic workspace. These practices cover everything from personal hygiene to safe handling, storage, and preparation techniques.

There are several key practices every worker should follow to ensure a safe environment:

- Personal Hygiene: Workers should wash their hands thoroughly and regularly, particularly before and after handling items, using the restroom, or after touching surfaces that could be contaminated.

- Proper Use of Protective Gear: Wearing gloves, aprons, and hairnets when necessary can prevent contamination. These items should be changed regularly and cleaned properly after each use.

- Safe Temperature Control: Maintain proper temperatures for both hot and cold items. Keep hot items above 140°F (60°C) and cold items below 40°F (4°C) to prevent bacterial growth.

- Clean Surfaces: Surfaces and utensils should be cleaned and sanitized regularly to avoid cross-contamination. Use separate cutting boards for raw and cooked items.

- Proper Waste Disposal: Dispose of trash and waste in a sanitary manner, ensuring that garbage bins are kept covered and emptied regularly to avoid attracting pests.

By following these basic safety practices, workers can help create a safer, healthier environment for everyone involved, minimizing the risk of contamination and ensuring the quality of the products served.

Answers to Frequently Asked Questions in Food Safety

Many individuals working in environments where consumables are prepared often have similar concerns and questions regarding best practices for maintaining safety. These frequently asked questions usually revolve around common practices, regulations, and troubleshooting when handling ingredients or serving meals. Addressing these questions can provide clarity and ensure that proper safety measures are consistently followed in the workplace.

Here are some common queries and their answers to help clarify key aspects of maintaining safety:

- What is the correct handwashing procedure? Hands should be washed thoroughly with soap and warm water for at least 20 seconds, especially before handling consumables or after touching any surfaces that may be contaminated.

- How do I avoid cross-contamination? Always use separate cutting boards, knives, and utensils for raw and cooked items. Keep raw ingredients away from ready-to-eat products to prevent harmful bacteria from spreading.

- What temperature should hot items be kept at? Hot items should be kept at or above 140°F (60°C) to ensure they remain safe for consumption and to prevent bacterial growth.

- How can I safely store perishable items? Store perishable items in the refrigerator or freezer immediately after purchasing or preparing them. Keep cold items below 40°F (4°C) and frozen items at 0°F (-18°C).

- How often should surfaces be sanitized? Surfaces that come into contact with consumables should be sanitized regularly throughout the day, especially between handling different ingredients or after cleaning up spills.

By understanding the answers to these common questions, workers can ensure a safer and more efficient work environment, minimizing risks and promoting a higher standard of hygiene in any setting where consumables are handled.

Dealing with Foodborne Illness Prevention

Preventing illness caused by contaminated consumables is crucial in any environment where products are prepared or served. Implementing proper safety measures helps protect consumers from harmful pathogens and reduces the risk of outbreaks. There are several key strategies that must be followed to ensure safety and minimize the chances of foodborne illnesses.

One of the most important aspects of prevention is maintaining cleanliness at all times. Regular sanitation of surfaces, utensils, and equipment helps eliminate bacteria and viruses that can cause illness. Additionally, it’s essential to manage temperatures properly, as improper handling of hot or cold items can promote bacterial growth. For example, keeping hot items above 140°F (60°C) and cold items below 40°F (4°C) is critical.

Another essential step is ensuring that workers understand and follow best practices for personal hygiene. This includes thorough handwashing, especially after touching raw materials, using the restroom, or handling garbage. Gloves and other protective equipment should be used appropriately, and changes made regularly to avoid cross-contamination.

Finally, awareness of potential contamination risks from external sources, such as pests or improper storage conditions, plays a critical role in food safety. Identifying and addressing these risks can significantly reduce the chances of contamination and help maintain a healthy environment for both workers and consumers.

Key strategies for preventing foodborne illness:

- Regular handwashing: Wash hands thoroughly with soap and warm water before handling consumables and after touching potential contaminants.

- Proper food storage: Store perishable items at safe temperatures and use FIFO (First In, First Out) to ensure freshness.

- Temperature control: Maintain proper temperatures for both hot and cold items to limit bacterial growth.

- Thorough cleaning and sanitizing: Clean and sanitize surfaces and equipment after every use, especially when handling raw ingredients.

- Use of protective gear: Wear gloves and aprons when needed and change them regularly to avoid cross-contamination.

By staying vigilant and following these preventive measures, the risk of foodborne illnesses can be minimized, ensuring a safe experience for both workers and customers.

Helpful Tips for Passing the Food Handler Exam

Successfully passing the certification exam for working with consumables requires preparation and understanding of key concepts. The test typically covers various aspects of hygiene, safety protocols, and best practices in handling products. To increase the chances of passing the exam, it’s important to focus on certain strategies and tips that can help you succeed.

One effective approach is to familiarize yourself with common topics that will appear on the test. Reviewing materials thoroughly and understanding the reasoning behind each rule is essential. This ensures that you’re not just memorizing information, but also grasping how and why certain practices are important. Additionally, practice with sample questions can help you get comfortable with the format and timing of the test.

It’s also beneficial to take regular breaks during study sessions. Continuous studying without breaks can lead to burnout and reduce retention. Breaks help refresh your mind and keep your focus sharp. Stay organized by creating a study plan and sticking to it, allowing you to cover all relevant topics without feeling rushed.

Below are some key tips to keep in mind when preparing for the exam:

- Understand the fundamentals: Be familiar with topics such as sanitation, temperature control, personal hygiene, and proper handling techniques.

- Review common safety protocols: Make sure you understand best practices for preventing contamination and the importance of maintaining safe working conditions.

- Practice with mock tests: Take advantage of online resources and sample tests to familiarize yourself with the types of questions and format.

- Stay calm and focused: Test anxiety can affect performance, so practice relaxation techniques and stay confident in your knowledge.

- Time management: Be mindful of time during the exam to ensure you can complete all questions without rushing.

By following these tips, you can approach the exam with confidence and increase your chances of achieving a passing score. With the right preparation and mindset, you’ll be well-equipped to demonstrate your knowledge and earn your certification.