Ensuring proper procedures and guidelines in a professional setting is crucial for maintaining safety and compliance. Workers must be equipped with the necessary knowledge to avoid risks and adhere to the standards that govern their responsibilities. Understanding the key principles behind safety practices allows individuals to perform their duties with confidence and professionalism.

Comprehensive preparation is essential for success when it comes to demonstrating competence in a regulated environment. Gaining insight into the most important topics and familiarizing oneself with common scenarios can make a significant difference when it’s time to showcase understanding. Proper knowledge not only improves performance but also ensures a safer working environment for everyone.

Examining relevant topics in depth and focusing on practical applications helps to enhance overall comprehension. From risk prevention to operational techniques, each concept plays a vital role in preventing common errors and maintaining industry standards. Effective preparation leads to better outcomes, making it easier to navigate tests and meet expectations with ease.

Responsible Practices for Certification Success

Achieving proficiency in safety and compliance requires more than simply memorizing guidelines. Understanding key principles and applying them effectively in various situations is essential for excelling in certification assessments. This section focuses on the most important topics to master, providing a clearer view of what is required to succeed.

Core Concepts to Focus On

When preparing for the certification process, there are several crucial areas to emphasize. These include practical knowledge of safety regulations, common hazards, and best practices in managing the working environment. The following are key concepts to study:

- Maintaining cleanliness and sanitation

- Recognizing common contamination sources

- Temperature control and safe handling methods

- Risk management and prevention techniques

- Recognizing signs of unsafe practices

Practical Tips for Mastery

To increase the chances of performing well, it’s helpful to familiarize yourself with potential scenarios and practice applying the concepts in real-world situations. Consider the following strategies to improve understanding:

- Review practical scenarios and how to handle each situation.

- Understand the importance of following established guidelines to prevent mistakes.

- Test your knowledge regularly through mock assessments or quizzes.

- Focus on areas that are commonly tested to ensure thorough understanding.

- Stay up to date with any changes to standards or regulations.

By mastering these concepts and applying effective strategies, individuals can confidently approach the assessment process, ensuring they meet industry standards and demonstrate their ability to maintain a safe working environment.

How to Prepare for the Assessment

Success in any certification process comes down to preparation. By focusing on the key principles and understanding the most important aspects of safety, individuals can increase their chances of passing with confidence. Knowing what to expect and how to approach the material is essential for effective learning.

Effective Study Techniques

To prepare effectively, it’s crucial to focus on the core areas and develop a study plan that prioritizes these topics. Here are some techniques to enhance your preparation:

- Break down the material into manageable sections.

- Create a study schedule that allows for regular review sessions.

- Focus on areas with the highest frequency of assessment.

- Practice applying concepts through real-world examples.

- Review guidelines and key regulations regularly.

Key Areas to Focus On

Certain topics are more likely to appear in the assessment, so it’s important to prioritize them in your study sessions. Key areas to concentrate on include:

- Proper handling and storage procedures

- Identifying hazards and preventing contamination

- Temperature control and its importance

- Understanding safety standards and regulations

- Recognizing signs of unsafe practices and knowing how to respond

By committing to these strategies and focusing on the right areas, individuals can approach the assessment confidently, knowing they are well-prepared for the challenge ahead.

Key Concepts in Safety Practices

Understanding the fundamental principles of maintaining a safe and hygienic environment is essential for anyone working in regulated sectors. These core concepts ensure that individuals are equipped to identify potential risks and take the necessary actions to mitigate them. Mastery of these principles is crucial for both personal and public well-being.

Fundamental Principles to Master

There are several essential concepts that must be understood to ensure safety and compliance in any workplace. The following areas are critical for maintaining high standards:

- Sanitation: Keeping the environment clean and free from contaminants.

- Contamination Prevention: Identifying and avoiding cross-contamination in the workplace.

- Temperature Control: Understanding safe temperature ranges for storage and preparation.

- Personal Hygiene: Maintaining high standards of personal cleanliness and health to prevent contamination.

- Risk Management: Identifying hazards and implementing effective strategies to reduce potential dangers.

Best Practices for Safety

To ensure that safety practices are consistently followed, individuals must adhere to best practices in all areas of their work. Here are some key actions to take:

- Regularly sanitize work surfaces and equipment.

- Use proper techniques for handling and storing materials to prevent contamination.

- Monitor and adjust temperatures to keep items at safe levels.

- Encourage the use of protective gear and proper handwashing.

- Stay informed about regulations and updates related to workplace safety.

By understanding and applying these key concepts, individuals can contribute to a safe, efficient, and compliant working environment, minimizing the risk of accidents and ensuring the highest standards are met.

Common Mistakes During the Test

Many individuals make avoidable errors during assessments, which can hinder their ability to demonstrate proficiency. These mistakes often arise from misunderstanding key concepts or rushing through questions without fully considering the best approach. Identifying these common pitfalls is essential for improving performance and achieving better results.

One of the most frequent errors is failing to carefully read each question. It is important to understand exactly what is being asked before providing an answer. Another common mistake is not paying enough attention to the details of safety procedures or regulations, which can lead to incorrect responses on critical points.

Additionally, some individuals may struggle with time management during the assessment. This can result in rushing through sections or leaving questions unanswered, which ultimately impacts the overall score. It is also important to stay focused and avoid second-guessing, as this can lead to mistakes that could otherwise be avoided.

By being mindful of these typical mistakes and taking steps to address them, individuals can approach the assessment with greater confidence and increase their chances of success.

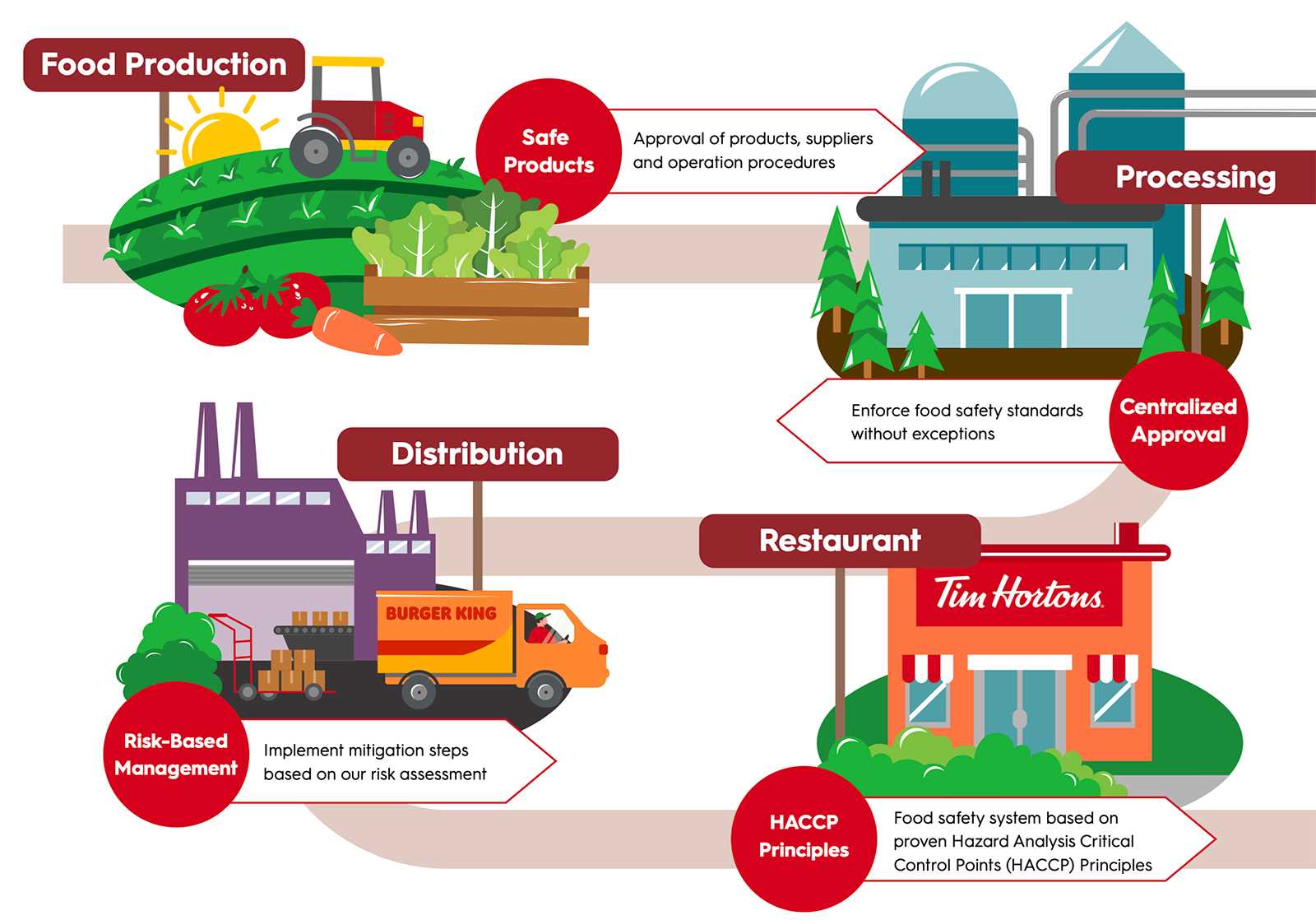

Understanding Food Handling Regulations

Comprehending the regulations that govern the safe management of products is essential for anyone involved in industries where health and safety are a priority. These standards are put in place to protect public well-being and ensure that the highest levels of hygiene are maintained. Understanding the rules surrounding proper practices is key to avoiding contamination and ensuring compliance with legal requirements.

Key Regulations to Know

There are several important regulations that must be followed to ensure safety in any environment where products are prepared, stored, or distributed. Here are the most crucial areas of focus:

- Sanitation Protocols: Regular cleaning of surfaces, equipment, and utensils to prevent the spread of harmful bacteria.

- Temperature Guidelines: Maintaining correct temperature ranges for both storage and preparation to minimize the risk of spoilage.

- Hygiene Standards: Ensuring that everyone involved in handling products adheres to strict personal hygiene practices.

- Risk Assessment: Identifying potential hazards and implementing measures to mitigate these risks.

- Labeling and Traceability: Proper labeling and tracking of products to ensure they meet regulatory requirements.

Compliance and Enforcement

Meeting these regulations is not just a matter of best practice; it is often a legal requirement. Regular inspections, audits, and certifications are conducted to ensure that businesses comply with established safety standards. Failure to adhere to these rules can result in fines, shutdowns, or even legal action. Therefore, it is important to stay informed about any updates to regulations and ensure that all practices are in line with current guidelines.

By staying educated and fully understanding these regulations, individuals can contribute to a safe, compliant working environment, ensuring that operations run smoothly and that public health is safeguarded.

Importance of Proper Storage Practices

Ensuring that products are stored correctly is a crucial aspect of maintaining safety and quality. Improper storage can lead to contamination, spoilage, and loss of nutritional value, ultimately posing risks to health and affecting the overall effectiveness of operations. Understanding the principles of safe storage is fundamental for anyone involved in handling and managing goods in environments where hygiene and safety are essential.

Proper storage practices help preserve the integrity of products, extend shelf life, and prevent the growth of harmful microorganisms. By following established guidelines, individuals can minimize the risk of contamination and ensure that goods remain fresh and safe for consumption or use. This also contributes to maintaining compliance with regulations designed to protect public health.

Key factors that influence effective storage include temperature control, proper organization, and the use of suitable containers. It’s important to monitor storage conditions regularly and ensure that items are kept in appropriate environments to prevent any risk of damage or contamination.

By prioritizing safe storage methods, businesses can operate more efficiently, reduce waste, and ensure the safety of both employees and consumers. Understanding the significance of these practices is a vital step in upholding high standards of cleanliness and safety within any regulated environment.

Role of Hygiene in Safety Practices

Maintaining cleanliness is a critical element in any setting where products are handled or prepared. Proper hygiene helps prevent contamination, ensuring that the environment remains safe and that the risk of harmful bacteria or pathogens spreading is minimized. It is essential for maintaining the integrity of operations and protecting public health.

Key Hygiene Practices to Follow

There are several hygiene practices that must be followed to ensure a clean and safe environment. These practices cover a wide range of actions, from personal hygiene to cleaning procedures, all of which play a vital role in preventing health risks. Below is a table outlining key hygiene measures and their importance:

| Hygiene Practice | Importance |

|---|---|

| Handwashing | Prevents the spread of bacteria and contaminants from hands to surfaces and products. |

| Proper Use of Gloves | Helps avoid direct contact with materials and reduces cross-contamination. |

| Cleaning Surfaces Regularly | Reduces the risk of harmful substances building up on work areas. |

| Sanitizing Equipment | Prevents the growth of harmful pathogens on utensils, tools, and machines. |

| Maintaining Personal Cleanliness | Ensures that individuals handling products do not introduce contamination through improper personal hygiene. |

Why Hygiene is Essential

Good hygiene practices are fundamental to ensuring the safety of any environment where products are handled or prepared. They are the first line of defense against contamination, which can lead to serious health issues. By adopting rigorous hygiene standards, businesses help protect not only their customers but also their employees and overall operational efficiency.

Types of Contaminants to Avoid

Understanding the different types of contaminants is crucial for maintaining a safe environment. These harmful substances can compromise the safety of products and lead to health risks. It’s essential to identify and prevent them from entering any space where goods are prepared, stored, or distributed.

Common Categories of Contaminants

Contaminants can be classified into several categories, each posing unique risks. These include biological, chemical, and physical contaminants, all of which require specific measures to prevent and control.

- Biological Contaminants: These include harmful microorganisms such as bacteria, viruses, fungi, and parasites. Common examples include Salmonella, E. coli, and Listeria.

- Chemical Contaminants: These consist of harmful chemicals that can contaminate products, such as pesticides, cleaning agents, and food additives that are improperly used or stored.

- Physical Contaminants: These are foreign objects like glass, metal, plastic, or wood that can accidentally enter products during processing or packaging.

Prevention and Control Measures

To avoid contamination, it is important to implement preventive measures such as proper sanitation, temperature control, and personal hygiene standards. Regular inspections, correct handling practices, and using appropriate storage techniques also play a key role in preventing contamination.

By being vigilant and understanding the types of contaminants, individuals can reduce the risk of harmful substances entering the environment and ensure safety standards are met at all times.

Safety Practices for Those Handling Products

Ensuring safety when working with consumables requires adherence to specific practices that minimize risks. Proper techniques help prevent contamination, maintain cleanliness, and ensure the products remain safe for consumption or use. These practices are essential for anyone involved in preparing, storing, or serving items in environments where hygiene is critical.

Key Safety Practices to Follow

To maintain a safe environment, there are several key practices that must be followed. These steps contribute to preventing contamination and ensuring that products remain uncontaminated throughout handling and storage.

- Hand Hygiene: Regular and thorough washing of hands is essential to remove dirt, bacteria, and other contaminants that can spread to products.

- Proper Personal Protective Equipment (PPE): The use of gloves, aprons, and hairnets prevents direct contact with products and minimizes the risk of contamination.

- Cross-Contamination Prevention: It is important to avoid the transfer of harmful substances between different items. This can be achieved by using separate tools, containers, and utensils for raw and cooked goods.

- Regular Cleaning: Keeping all surfaces, utensils, and equipment sanitized reduces the buildup of germs and prevents cross-contamination.

Staying Informed and Updated

Adhering to safety protocols is an ongoing process. Staying up to date with the latest regulations, guidelines, and best practices ensures that the highest safety standards are maintained. Regular training and reinforcement of these practices are key to achieving long-term success in maintaining a safe working environment.

How to Manage Cross-Contamination

Preventing the transfer of harmful substances between items is essential for ensuring safety in any environment where products are prepared or handled. Cross-contamination occurs when bacteria, allergens, or other harmful agents are unintentionally transferred from one surface, object, or product to another. Effective management of this process is crucial to avoid health risks and maintain a safe environment for everyone involved.

To successfully manage cross-contamination, it is important to follow strict protocols and implement precautionary measures at all stages of handling. This includes using proper equipment, maintaining hygiene, and ensuring that tasks are carried out in a systematic and controlled manner. Preventing the transfer of contaminants requires vigilance and adherence to safe practices.

Some of the key steps to manage cross-contamination effectively include:

- Ensuring the use of separate utensils, cutting boards, and containers for raw and cooked items.

- Regularly sanitizing surfaces and equipment to eliminate any harmful residues.

- Properly storing items to prevent contact between raw and ready-to-eat products.

- Training individuals to recognize potential risks and follow best practices for cleanliness and hygiene.

- Using color-coded tools or designated areas to clearly distinguish between different types of tasks and materials.

By maintaining strict control over these processes, cross-contamination can be effectively managed, safeguarding the quality and safety of products and protecting the health of everyone involved.

Temperature Control for Safe Food Handling

Proper temperature management is crucial in maintaining the safety and quality of items. By controlling the temperature during storage, preparation, and serving, harmful microorganisms that cause illness can be prevented from growing and spreading. Understanding the temperature range for safe handling is essential for reducing the risk of contamination and ensuring the safety of consumers.

To achieve effective temperature control, it is important to monitor and maintain specific temperature ranges throughout the process. These include proper refrigeration, heating, and holding temperatures to prevent the growth of harmful pathogens. Regular checks and using the right tools can ensure that temperature guidelines are followed consistently.

Here are some key practices for managing temperature effectively:

- Proper Refrigeration: Always store perishable items at the correct temperature (typically below 40°F/4°C) to slow bacterial growth.

- Safe Cooking Temperatures: Cook items to the appropriate internal temperatures to kill harmful microorganisms (e.g., 165°F/74°C for poultry).

- Hot Holding: Keep ready-to-eat items hot (above 140°F/60°C) until served to prevent bacterial growth.

- Cold Holding: Maintain cold items at or below 40°F/4°C to ensure safety until consumption.

- Temperature Monitoring: Use thermometers to regularly check the temperature of storage units, cooking equipment, and prepared items.

By implementing and following these temperature control measures, risks associated with harmful microorganisms can be minimized, ensuring safe and high-quality products for consumption.

Test Tips for Safety Certification

Successfully passing a certification test requires a thorough understanding of key concepts and a focused approach to preparation. Effective study habits, a clear understanding of safety protocols, and familiarity with common test formats are essential for achieving success. Being well-prepared ensures that you can confidently demonstrate your knowledge and apply safety practices in real-world scenarios.

Here are some valuable tips to help you prepare for and succeed in a safety certification test:

- Review Key Safety Principles: Focus on core concepts such as hygiene, contamination prevention, temperature control, and proper handling techniques.

- Understand Common Risks: Familiarize yourself with potential hazards, such as bacterial growth, allergens, and cross-contamination, and how to mitigate them.

- Practice with Mock Tests: Take practice exams to familiarize yourself with the format and types of questions that may appear on the actual test.

- Stay Calm and Focused: During the test, stay composed and read each question carefully. Manage your time wisely to ensure you can address all questions.

- Ask Questions if Needed: If allowed, don’t hesitate to ask for clarification on any confusing questions to avoid misunderstandings.

By following these tips and staying committed to your preparation, you’ll be well-equipped to succeed and obtain the certification needed to ensure safety and compliance in your role.

How to Interpret Safety Guidelines

Understanding and correctly interpreting safety regulations is crucial for maintaining a safe environment, particularly in settings that involve preparing and handling products. Guidelines are often presented in a structured manner, providing detailed instructions on procedures, standards, and the expectations that must be met. It’s important to not only read but fully comprehend the rationale behind these rules to apply them effectively in day-to-day practices.

When interpreting safety guidelines, it’s essential to focus on key areas and break down complex instructions into manageable parts. Here are some strategies for better understanding and applying these guidelines:

1. Know the Standards

Each guideline has specific standards that must be met to ensure safety and compliance. Understand the threshold limits and recommended practices for each area, such as temperature ranges, handling protocols, and cleanliness procedures. Familiarize yourself with these standards to ensure that actions align with the required safety measures.

2. Identify the Rationale

Guidelines often come with explanations detailing why a particular practice is necessary. Grasping the reasoning behind these recommendations helps in recognizing their importance and encourages adherence to the standards. Understanding the science behind safety protocols can also help in making better decisions when faced with unusual circumstances.

- Focus on Critical Points: Identify which aspects of the guidelines are non-negotiable, such as temperature limits and hygiene rules, and prioritize them in your daily operations.

- Clarify Ambiguities: If any part of the guidelines is unclear, consult additional resources, such as industry references or safety experts, to ensure proper interpretation.

- Review Regularly: Safety guidelines are frequently updated. Regularly review the most current information to stay informed of any changes or additions to the regulations.

By carefully studying safety guidelines and understanding their rationale, individuals and organizations can confidently apply them to maintain a safe, compliant, and efficient environment.

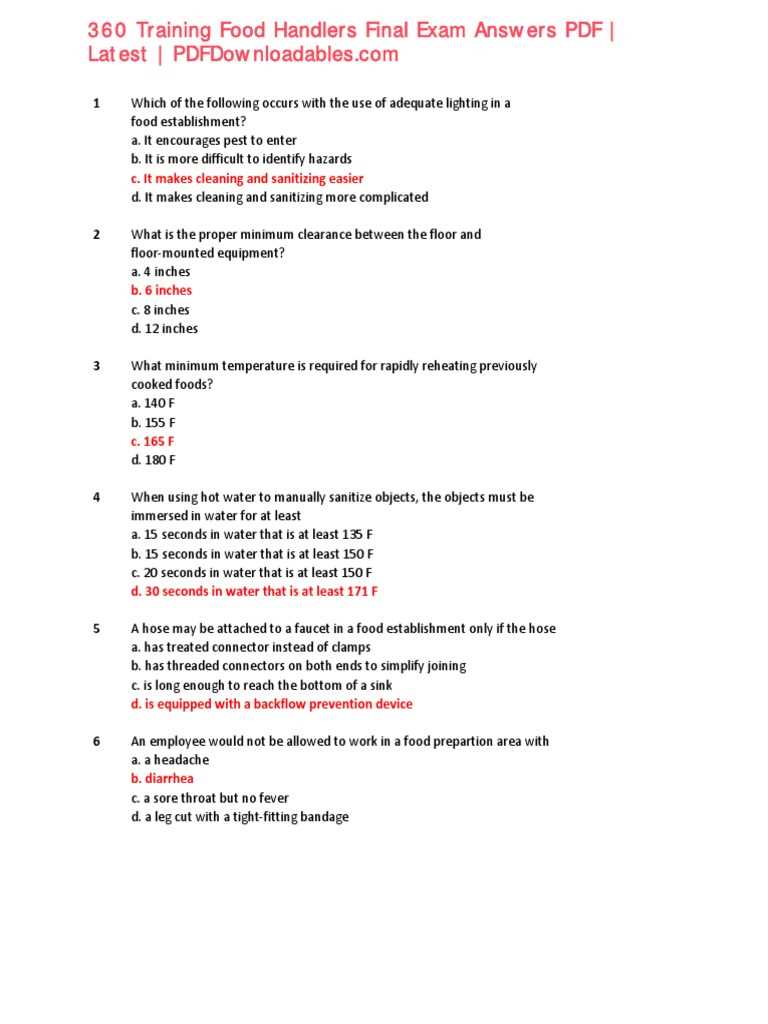

Common Questions and Correct Responses

When preparing for assessments in areas involving health and safety practices, there are several key topics that frequently appear. Understanding these common questions and how to respond accurately is essential for success. Below are some typical inquiries along with their ideal responses to help you prepare thoroughly.

1. What is the Ideal Temperature for Storing Perishables?

One of the most common areas of focus is temperature control. Proper temperature management is essential to prevent bacterial growth and ensure safe consumption. Here is the recommended response:

| Question | Correct Response |

|---|---|

| What is the ideal temperature for storing perishable items? | Perishable items should be stored at or below 40°F (4°C) to prevent harmful bacteria from multiplying. |

2. How Can Cross-Contamination Be Prevented?

Cross-contamination is a major concern in maintaining hygiene and safety. Understanding how to effectively avoid it is often tested. The typical answer would include the following:

| Question | Correct Response |

|---|---|

| How can cross-contamination be prevented? | Use separate equipment for raw and cooked items, wash hands frequently, and store different food categories in designated areas. |

By familiarizing yourself with these common questions and the proper responses, you can ensure you are well-prepared for any upcoming assessments or practical evaluations. Understanding the concepts behind these answers will also help solidify your ability to apply the knowledge in real-world scenarios.

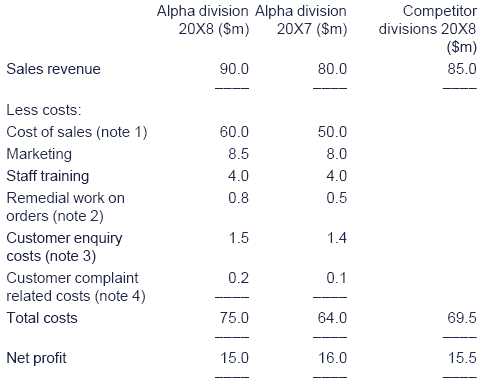

What to Expect on the Assessment

When preparing for an assessment in safety and hygiene practices, it’s essential to understand what to anticipate. These evaluations often include a variety of topics related to sanitation, proper handling procedures, and regulatory requirements. By being familiar with the structure and content, you can approach the evaluation confidently and with the right preparation.

The assessment typically includes multiple sections that focus on critical areas of practice. Below are the key components you may encounter during the evaluation:

| Section | Description |

|---|---|

| Health and Hygiene | This section covers the essential personal hygiene practices required to prevent contamination and maintain a safe environment. |

| Temperature Control | Questions related to the correct storage temperatures for various items to avoid bacterial growth and contamination. |

| Cross-Contamination | Understanding how to prevent the transfer of harmful bacteria from raw to cooked items or between different categories of products. |

| Regulatory Compliance | Questions on local, state, and federal guidelines related to safe practices in handling items in the industry. |

Each section may include multiple-choice questions, true or false statements, and scenario-based questions that test your understanding of the material. Being prepared to answer these will help ensure you pass the assessment successfully and with ease.

Understanding Foodborne Illness Prevention

Preventing illnesses caused by contaminated products is a critical aspect of maintaining safety in any environment that handles consumable items. By understanding the key practices that minimize the risk of contamination, one can significantly reduce the chances of harmful pathogens affecting individuals. Effective prevention involves implementing proper techniques, ensuring cleanliness, and being aware of common sources of contamination.

Several basic practices are essential for preventing the spread of harmful bacteria and viruses that can cause illness. These include:

- Personal Hygiene: Consistently practicing good hygiene, such as washing hands regularly and using gloves, is crucial in avoiding the transfer of pathogens.

- Proper Cleaning: Ensuring that all surfaces, equipment, and utensils are cleaned and sanitized properly is fundamental in maintaining a safe environment.

- Temperature Control: Keeping items at the correct temperatures prevents the growth of harmful microorganisms, which thrive in unsafe ranges.

- Avoiding Cross-Contamination: It’s essential to separate raw items from ready-to-eat ones to prevent the transfer of harmful bacteria from one to the other.

- Storage and Handling: Properly storing items and ensuring that they are not left out for extended periods helps limit the chances of contamination.

By being aware of these fundamental preventive measures, those involved in the handling process can significantly reduce the likelihood of foodborne illnesses. Proper education, adherence to safety protocols, and continuous vigilance are key to maintaining public health and safety.

Examining the Safe Food Handling Procedures

Ensuring the safety of consumables during preparation and distribution is vital to prevent contamination and protect public health. The processes involved in managing consumables safely are designed to minimize risks associated with improper practices. These steps help avoid the spread of harmful pathogens and ensure that products are safe for consumption.

Key Practices in Safe Handling

To maintain safety, certain procedures must be followed meticulously. These practices include:

- Personal Hygiene: Always wash hands thoroughly before handling consumables, especially after touching raw items, using the restroom, or handling waste.

- Cleaning and Sanitizing: Regular cleaning and sanitizing of surfaces, tools, and equipment reduce the risk of contamination.

- Temperature Control: Keep items at the correct temperature to prevent the growth of harmful microorganisms. This includes refrigeration, hot holding, and proper cooking temperatures.

- Separation of Raw and Ready-to-Eat Items: Prevent cross-contamination by keeping raw items separate from those that are ready to eat.

- Proper Storage: Store products in a safe, hygienic manner, ensuring that they are not exposed to conditions that promote the growth of harmful pathogens.

Implementation and Adherence

All individuals involved in managing consumables must adhere to these procedures consistently. This includes regular training and reinforcement of safety protocols. Following the recommended guidelines ensures that contamination risks are minimized and that consumables are handled with the utmost care.

Post-Exam Certification and Next Steps

Once the assessment process is completed successfully, individuals receive certification that validates their knowledge and competence in maintaining safety standards. This certification signifies that the person is well-prepared to handle responsibilities with awareness of critical procedures and regulations. The next steps involve applying this knowledge in real-world settings while continuing to build expertise in the field.

After obtaining certification, individuals should focus on the following key areas to further their professional growth:

- Practical Application: Implement the learned safety practices in daily tasks, ensuring consistent adherence to standards for hygiene, temperature control, and contamination prevention.

- Ongoing Learning: Stay informed about updates to regulations and best practices. Participate in refresher courses or training sessions to ensure knowledge remains current.

- Engage with Industry Communities: Join relevant industry networks to exchange experiences, share challenges, and stay updated on new trends in safety and compliance.

- Seek Additional Certifications: Consider pursuing advanced certifications or specializations to further enhance career prospects and expertise in the field.

By continuing to expand skills and applying knowledge in practice, individuals ensure they are prepared to contribute to a safer environment and uphold industry standards effectively.