When it comes to maintaining hygiene and ensuring health standards in the culinary industry, knowledge plays a crucial role. Many individuals working in food-related environments must demonstrate their understanding of essential safety practices. Certification exams test this knowledge, focusing on key concepts related to sanitation, temperature control, and proper handling techniques.

Preparing for such an exam requires familiarity with common questions, procedures, and best practices that ensure the safety of both consumers and staff. By mastering these principles, you can confidently navigate the exam and meet the required standards set by authorities in the industry. This guide will provide you with the necessary tools and insights to succeed and enhance your professional expertise.

Food Safety Certification Exam Insights

To excel in the exam designed for professionals in the culinary and service industries, it’s essential to understand core principles surrounding hygiene, sanitation, and safe practices. The assessment tests individuals on their ability to apply knowledge effectively in real-world settings, ensuring that safety standards are met in various environments.

Preparing for the examination requires a thorough grasp of the following key areas:

- Proper sanitation practices – Understanding the cleaning and disinfecting protocols essential for preventing contamination.

- Temperature control – Knowing the appropriate temperatures for storing, cooking, and serving products to avoid the growth of harmful bacteria.

- Personal hygiene – Recognizing the importance of handwashing and other personal cleanliness measures to prevent cross-contamination.

- Cross-contamination prevention – Identifying practices that reduce the risk of allergens and pathogens being transferred between surfaces and products.

- Food storage techniques – Proper methods for storing items to maintain their quality and safety.

Additionally, the exam often includes questions related to recognizing common signs of contamination, knowing how to react in emergency situations, and understanding the rules set by health agencies.

Familiarity with these topics will not only help you pass the test but also strengthen your knowledge and skills for maintaining a safe environment in the workplace. The next step is to review practice questions, ensure you understand each concept, and be confident in your preparation.

Understanding the Importance of Food Safety

Ensuring that products are handled, prepared, and stored in a hygienic and safe manner is essential for protecting public health. The goal is to minimize risks such as contamination, spoilage, and the spread of harmful bacteria or viruses. Professionals working in environments where consumables are prepared must be knowledgeable about how to properly manage these risks to ensure the well-being of consumers.

Protecting Consumers from Health Risks

One of the primary reasons for maintaining proper hygiene and safety standards is to prevent foodborne illnesses. These illnesses can result from improper handling, poor temperature regulation, or cross-contamination between different ingredients. By understanding how to properly store, cook, and serve products, workers can significantly reduce the chances of harmful pathogens affecting consumers’ health.

Ensuring Workplace Compliance

In addition to health concerns, adhering to industry regulations is crucial. Many regions have specific guidelines and standards that businesses must follow to remain compliant with health and safety laws. Professionals need to stay informed about these regulations to avoid legal issues, fines, or the closure of their establishment. Proper certification ensures that individuals are aware of these standards and can implement them effectively in their work environment.

Key Concepts for the Exam

To succeed in the certification assessment, it’s important to familiarize yourself with the fundamental principles that will be tested. The exam evaluates your understanding of practices that ensure safety, hygiene, and proper management of consumable items. By mastering these essential concepts, you can approach the test with confidence and meet industry standards for maintaining a healthy environment.

Some of the key areas that you should focus on include:

- Sanitation practices – Knowing how to properly clean and disinfect surfaces, utensils, and equipment to prevent contamination.

- Temperature control – Understanding the correct temperatures for storing, cooking, and holding various products to avoid bacterial growth.

- Cross-contamination prevention – Learning how to handle different types of products separately to reduce the risk of harmful substance transfer.

- Personal hygiene – Emphasizing the importance of handwashing and cleanliness to prevent the spread of contaminants.

- Storage techniques – Understanding how to store items safely to maintain quality and minimize the risk of spoilage.

By focusing on these key concepts, you can ensure that you are well-prepared for the exam and equipped with the knowledge needed to contribute to a safe working environment.

Common Mistakes to Avoid

When preparing for the certification exam, it’s crucial to be aware of common pitfalls that can hinder your success. Many individuals unknowingly overlook certain details or misunderstand key concepts, which can lead to incorrect answers and lower scores. Understanding these frequent mistakes will help you focus on the right areas and improve your chances of passing the exam on the first try.

Here are some of the most common errors to avoid:

- Neglecting proper hand hygiene – Failing to wash hands thoroughly or at the right times can lead to contamination, even if other practices are followed correctly.

- Ignoring temperature guidelines – Misunderstanding the correct temperature ranges for storing or cooking products can allow harmful bacteria to thrive.

- Inconsistent cleaning routines – Skipping or rushing through cleaning and sanitizing procedures may leave harmful pathogens on surfaces or equipment.

- Mixing raw and cooked items – Not keeping raw and ready-to-eat products separate can lead to cross-contamination and the spread of illness-causing bacteria.

- Overlooking storage methods – Failing to store items properly, such as not sealing containers correctly or leaving food out too long, can lead to spoilage or contamination.

Avoiding these mistakes will not only help you pass the exam but also ensure that you maintain high safety standards in any work environment. Being mindful of these details will set you on the path to success and professionalism.

How to Prepare for the Test

Proper preparation is the key to performing well on the certification exam. It is important to focus on both understanding the core concepts and practicing how to apply that knowledge in various situations. With the right strategy, you can increase your chances of success and feel confident on the day of the test.

Study the Key Topics

Familiarize yourself with the main concepts that will be tested, such as hygiene, temperature management, and contamination prevention. The more you understand these topics, the easier it will be to answer the questions accurately. Here are some of the essential areas to focus on:

| Topic | Description |

|---|---|

| Sanitation | Learn how to properly clean and sanitize surfaces, tools, and hands to prevent contamination. |

| Temperature Control | Understand the correct temperature ranges for storing and cooking products safely. |

| Cross-Contamination | Know how to prevent harmful substances from being transferred between items. |

| Personal Hygiene | Understand the importance of handwashing and personal cleanliness to maintain a safe environment. |

| Food Storage | Learn the correct methods for storing items to avoid spoilage and maintain freshness. |

Practice with Sample Questions

Testing your knowledge with practice questions is one of the best ways to prepare. Many resources offer mock exams that simulate the actual test environment. Take these tests to assess your readiness and identify areas where you may need further review. By practicing under timed conditions, you’ll become more comfortable with the format and improve your speed and accuracy.

Typical Questions on the Test

The certification exam typically includes a variety of questions designed to test your understanding of essential safety practices in the workplace. These questions often focus on key concepts such as hygiene, contamination prevention, and proper management of consumables. Familiarizing yourself with the types of questions you might encounter can help you prepare effectively and boost your confidence.

General Knowledge and Best Practices

Many of the questions will assess your knowledge of basic health and safety guidelines, such as:

- What is the proper handwashing technique?

- At what temperature should perishable items be stored?

- How should raw products be separated from ready-to-eat items?

- What should be done when a foodborne illness outbreak is suspected?

Scenario-Based Questions

Other questions will present you with real-world scenarios to evaluate your ability to apply what you’ve learned. These may include situations such as:

- What steps would you take if a customer reports an allergic reaction?

- If you find a broken refrigeration unit, how should you handle the items inside?

- How would you prevent cross-contamination in a busy kitchen?

By reviewing these typical questions and practicing your responses, you can better prepare for the test and ensure that you’re ready to demonstrate your knowledge in any given situation.

What to Expect During the Exam

When you take the certification test, you can expect a series of questions designed to assess your understanding of essential safety and hygiene practices. The exam is structured to test both your theoretical knowledge and your ability to apply that knowledge in real-world situations. It’s important to be prepared for a variety of question formats, including multiple-choice, true/false, and scenario-based questions.

The test typically follows these steps:

- Timed Format – Most exams are timed, so it’s important to manage your time efficiently. You will likely have a set period to complete all the questions, so pace yourself accordingly.

- Multiple-Choice Questions – These questions will ask you to select the correct answer from a list of options. They will cover topics like sanitation, temperature control, and personal hygiene.

- Scenario-Based Questions – Some questions will present hypothetical situations where you’ll need to choose the best course of action based on safety practices. For example, you may need to decide how to handle a situation involving cross-contamination or improper food storage.

- Pass/Fail Results – At the end of the exam, you’ll typically receive immediate feedback on whether you’ve passed or need to retake the test. If you don’t pass, most testing platforms will provide guidance on areas to review.

It’s normal to feel a bit nervous, but remember that the exam is designed to ensure that you are equipped with the necessary skills to maintain a safe and hygienic environment. With proper preparation, you can approach the test with confidence.

Commonly Asked Questions Explained

When preparing for the certification test, many candidates have similar questions regarding the material, test format, and preparation process. Addressing these commonly asked questions can help clarify any doubts and ensure you’re fully prepared. Here, we will explain some of the most frequently raised concerns and provide you with clear answers to guide your preparation.

1. How long is the exam?

The duration of the test typically ranges from 30 minutes to an hour, depending on the platform or institution administering it. Be sure to check the guidelines beforehand to know exactly how much time you’ll have to complete the questions.

2. What type of questions can I expect?

Expect a mix of multiple-choice, true/false, and scenario-based questions. These will test your knowledge of hygiene, safety practices, and proper handling techniques. The questions are designed to assess both theoretical understanding and practical application of key concepts.

3. What is the passing score?

The passing score generally falls around 70% to 80%, though this may vary. Be sure to review the specific passing criteria for the exam you’re taking. If you do not pass on your first attempt, you will usually have the opportunity to retake the test after reviewing the material.

4. How should I prepare for the exam?

Review the key topics such as sanitation, temperature control, cross-contamination prevention, and personal hygiene. Practice with sample questions to familiarize yourself with the format and identify areas where you may need more study. Time management is also crucial, so practice answering questions within the allotted time.

5. Is there a study guide available?

Many testing platforms provide official study materials or guides. These resources can be very helpful for focusing your preparation on the areas most likely to be covered in the exam. Take advantage of these guides to ensure you’re well-prepared.

Foodborne Illnesses and Prevention

Foodborne illnesses are a significant concern in any environment that handles consumables. These illnesses are caused by harmful microorganisms, chemicals, or other contaminants that can be ingested through improperly handled products. Preventing these illnesses requires a solid understanding of safety practices and proper techniques for handling, storing, and preparing items.

There are various pathogens and contaminants that can lead to foodborne illnesses. These include bacteria, viruses, and parasites, each with distinct characteristics. The key to preventing illness lies in controlling the factors that allow these harmful agents to thrive, such as temperature, hygiene, and cross-contamination.

| Pathogen | Symptoms | Prevention |

|---|---|---|

| Salmonella | Diarrhea, fever, abdominal cramps | Cook to proper temperatures, avoid cross-contamination |

| Norovirus | Vomiting, nausea, stomach cramps | Wash hands thoroughly, clean surfaces often |

| E. coli | Severe stomach cramps, diarrhea, vomiting | Use proper food storage and handling, avoid undercooked meat |

| Listeria | Flu-like symptoms, muscle aches, diarrhea | Keep perishable items at safe temperatures, clean food prep areas |

| Campylobacter | Diarrhea, abdominal pain, fever | Cook meat properly, prevent cross-contact with raw products |

Preventing foodborne illnesses involves maintaining safe practices, such as regular handwashing, proper sanitation, monitoring temperatures, and preventing cross-contamination. By adhering to these guidelines, you can significantly reduce the risk of illness and ensure a safe environment for all consumers.

Best Practices for Safe Food Handling

Maintaining a clean and safe environment is critical in preventing contamination and ensuring that items prepared for consumption are safe. Proper handling practices, hygiene, and organization play a crucial role in reducing the risks associated with pathogens and spoilage. Following industry-standard guidelines can protect both consumers and workers.

Key Principles for Safe Handling

- Proper Handwashing: Always wash your hands thoroughly before and after handling products, especially after touching raw items or using the restroom.

- Temperature Control: Store perishables at the correct temperatures and ensure hot items are kept above 140°F (60°C) and cold items below 41°F (5°C) to prevent bacterial growth.

- Cross-Contamination Prevention: Use separate tools and surfaces for raw and cooked items. Avoid using the same cutting board for vegetables and raw meats.

- Regular Cleaning: Clean surfaces, utensils, and equipment frequently to eliminate harmful microorganisms and prevent cross-contamination.

- Labeling and Rotation: Always label products with expiration dates and rotate stock to use older items first (FIFO – First In, First Out).

Steps for Safe Preparation

- Ensure all items are washed thoroughly before preparation, including fruits and vegetables that will not be cooked.

- Cook items to the correct internal temperature to destroy any harmful bacteria.

- Once prepared, keep food covered and at the appropriate temperature until ready to serve.

- Ensure that food does not sit out for extended periods, as this can lead to bacterial growth and spoilage.

- Dispose of any items that have been improperly stored or are beyond their safe consumption date.

By following these best practices, you can create a safer environment for everyone involved, reducing the risk of contamination and ensuring that items are safe to consume.

Understanding Temperature Control

Effective temperature management is crucial for maintaining the safety and quality of consumables. Harmful microorganisms thrive in specific temperature ranges, so controlling the environment where products are stored, prepared, and served is essential to preventing contamination and spoilage. By following proper temperature guidelines, you can significantly reduce the risk of illness.

Temperature Danger Zones

Microorganisms grow most rapidly within a specific temperature range, often referred to as the “danger zone.” This zone is typically between 41°F (5°C) and 135°F (57°C). To minimize the risk of contamination, it is vital to keep products outside of this temperature range, both during storage and while in preparation.

- Hot Holding: Keep hot items at or above 140°F (60°C) to prevent bacterial growth.

- Cold Storage: Store perishable items below 41°F (5°C) to slow bacterial development.

- Rapid Cooling: When cooling cooked items, ensure they are brought down to below 41°F (5°C) within two hours to avoid staying in the danger zone for too long.

Tools for Temperature Monitoring

Accurate temperature monitoring is essential in maintaining a safe environment. Some of the best tools for checking temperatures include:

- Thermometers: Use a food-grade thermometer to measure internal temperatures of prepared items.

- Infrared Thermometers: Ideal for quick surface temperature readings, these devices can be used to monitor holding equipment.

- Temperature Logs: Keep a daily log of temperatures for storage units, cooking areas, and hot-holding stations to ensure compliance.

By understanding and practicing proper temperature control, you ensure that harmful bacteria are kept at bay and that products remain safe for consumption.

Hand Hygiene and Its Importance

Maintaining clean hands is a fundamental aspect of preventing contamination and ensuring a safe environment in any setting where consumables are handled. Hands can transfer harmful microorganisms from one surface to another, which is why proper hygiene is crucial for minimizing health risks. Regular handwashing and sanitizing can significantly reduce the spread of germs and protect consumers from illness.

Proper hand hygiene involves more than just washing hands with soap and water; it requires thorough techniques and understanding the key times when cleaning is necessary. Regular handwashing practices can help eliminate germs that might otherwise go unnoticed.

When to Wash Your Hands

There are certain critical moments when washing hands becomes even more essential. These include:

| Situation | Action |

|---|---|

| Before handling any items | Wash hands thoroughly with soap and water |

| After using the restroom | Wash hands with soap for at least 20 seconds |

| After coughing, sneezing, or touching the face | Sanitize hands or wash them immediately |

| After handling raw ingredients | Clean hands before proceeding with other tasks |

| Before eating or drinking | Wash hands to avoid ingesting contaminants |

Effective Handwashing Techniques

It’s important to follow the correct steps when washing hands to ensure proper sanitation. These include:

- Wet hands: Use clean, running water to wet hands before applying soap.

- Scrub thoroughly: Lather soap between your fingers, under nails, and the backs of your hands.

- Rinse well: Make sure all soap is removed from your hands using clean water.

- Dry properly: Dry your hands with a clean towel or air dryer to prevent recontamination.

By adhering to proper hand hygiene practices, you help ensure a safer environment for everyone, reducing the likelihood of foodborne illnesses and cross-contamination.

Cross-Contamination and How to Prevent It

Cross-contamination occurs when harmful microorganisms are transferred from one surface or item to another, leading to contamination. This can happen in various environments, particularly in areas where consumables are prepared or handled. It is crucial to understand how cross-contamination occurs and how to take proactive steps to prevent it to ensure a safe and hygienic environment.

Preventing cross-contamination is a critical part of maintaining cleanliness and safety. Whether it’s through proper storage, cleaning techniques, or maintaining a hygienic workspace, reducing the risk of transferring contaminants is key to avoiding illness.

Common Ways Cross-Contamination Happens

Cross-contamination can take place in several ways. Recognizing the most common sources is the first step to controlling it:

- Improper Handling: Using the same utensils or surfaces for raw and cooked items without cleaning them in between.

- Storage Issues: Storing raw ingredients above ready-to-eat items, causing drips and leaks that can contaminate other products.

- Unwashed Hands: Not washing hands properly after handling raw items, leading to the spread of germs to surfaces or other ingredients.

- Contaminated Equipment: Using unclean cutting boards, knives, or containers that have come into contact with harmful pathogens.

Effective Strategies to Prevent Cross-Contamination

There are several practical steps that can be taken to minimize the risk of cross-contamination:

- Separate Raw and Ready-to-Eat Items: Store raw products in separate containers, and ensure they are kept below or away from ready-to-eat items.

- Clean and Sanitize Regularly: Clean surfaces, utensils, and equipment after each use, particularly when switching between different types of ingredients.

- Use Color-Coded Tools: Assign specific cutting boards and knives for different food types, such as raw meats, vegetables, and ready-to-eat items, to avoid accidental cross-contact.

- Proper Handwashing: Wash hands thoroughly and frequently, especially after handling raw ingredients or touching potentially contaminated surfaces.

- Use Protective Barriers: Gloves or utensils can be used to handle ready-to-eat items, minimizing the risk of contamination from direct contact with hands.

By understanding and implementing these preventive measures, it is possible to create a safer environment, reducing the likelihood of transferring harmful microorganisms and protecting the health of everyone involved.

Cleaning and Sanitizing Procedures

Maintaining a clean and sanitized environment is essential in preventing contamination and ensuring the safety of all products and surfaces. Effective cleaning and sanitizing help remove harmful microorganisms that can lead to illness, making it a fundamental practice in any setting where consumables are prepared or handled. Understanding the distinction between cleaning and sanitizing, as well as implementing proper procedures, is crucial to maintaining high standards of hygiene.

Cleaning involves the removal of visible dirt, grease, and debris, while sanitizing focuses on reducing harmful pathogens to safe levels. Both processes must be performed regularly and correctly to ensure the safety of the environment and the people involved.

Key Steps in the Cleaning Process

To achieve proper cleaning, follow these essential steps:

- Remove Debris: Begin by clearing all surfaces and equipment of any visible dirt, food scraps, or other debris. This prepares the area for a more thorough clean.

- Use Appropriate Detergents: Select cleaning products that are suitable for the type of surface being cleaned. Ensure that the detergent is effective in breaking down grease and dirt.

- Scrub Surfaces: Use brushes, cloths, or pads to scrub surfaces, focusing on areas with heavy buildup, such as counters, utensils, and machinery.

- Rinse Thoroughly: After cleaning, rinse surfaces with clean water to remove any remaining detergent or dirt particles.

Sanitizing Techniques

Sanitizing is the final step to ensure that harmful microorganisms are reduced to safe levels. Follow these procedures for effective sanitizing:

- Choose the Right Sanitizer: Select a sanitizer that is appropriate for the surfaces being treated. There are various options, such as chlorine bleach or quaternary ammonium compounds, each suited for different environments.

- Apply Proper Concentration: Always dilute the sanitizer according to the manufacturer’s instructions. Too much or too little can either be ineffective or cause damage.

- Allow for Contact Time: Ensure that the sanitizer is left on the surface for the required amount of time to effectively reduce microbial contamination. This is often referred to as “contact time.”

- Air Dry or Use Clean Towels: Allow sanitized surfaces to air dry, or use clean towels to wipe down surfaces if necessary. Avoid using the same towel for multiple surfaces to prevent re-contamination.

By consistently following proper cleaning and sanitizing protocols, harmful contaminants can be significantly reduced, ensuring a safe environment for all individuals involved in the preparation and handling process.

Food Storage and Safety Guidelines

Proper storage of consumables is critical to prevent contamination, spoilage, and the growth of harmful pathogens. Ensuring that products are stored in the correct environment and in accordance with safety standards helps maintain their quality and safety. Following established guidelines can significantly reduce the risk of illness caused by improper handling and storage.

Storage procedures include the organization of items to avoid cross-contamination, maintaining the right temperatures, and ensuring that containers are clean and safe for use. Additionally, the proper rotation of stock helps ensure that older items are used first, preventing them from spoiling and reducing waste.

Essential Storage Tips

- Temperature Control: Ensure that items are stored at the proper temperatures to prevent bacterial growth. Perishable goods should be kept in cool or frozen environments, while dry goods should be stored in a dry, cool place.

- Proper Packaging: Use airtight containers or appropriate wraps to keep items sealed. This helps maintain freshness and prevents contamination from outside sources.

- Separation of Raw and Cooked Products: Always store raw items separately from cooked products to prevent cross-contamination. This can be done by using designated storage containers or shelves.

- Labeling: Clearly label all items with the date they were stored. This practice ensures that items are used within their recommended time frame and can help prevent foodborne illness caused by expired products.

Safe Handling During Storage

- Avoid Overcrowding: Ensure that storage areas have enough space for air to circulate around products. Overcrowding can prevent proper cooling and lead to uneven temperatures, increasing the risk of spoilage.

- Regular Inspections: Periodically check storage areas to ensure that temperatures are within safe limits and that no items have been compromised or contaminated.

- Rotate Stock: Implement the “First In, First Out” (FIFO) system to ensure that older products are used before newer ones. This helps reduce the likelihood of spoiled goods.

By following these guidelines and maintaining a clean, organized storage environment, it is possible to minimize the risks of contamination and spoilage, ensuring that all items remain safe and high-quality for consumption.

Benefits of Getting Certified

Obtaining certification in safe practices offers a wide range of advantages, both for individuals and businesses. It demonstrates a commitment to upholding high standards of safety and hygiene, which can significantly improve overall operations. Certified individuals are equipped with essential knowledge to prevent risks and handle products in a way that prioritizes public health.

Additionally, gaining certification can increase credibility and open up new opportunities. Employers often prefer candidates with certification as it shows they are well-versed in industry standards and capable of contributing to a safe working environment. It also boosts consumer confidence when they know that staff members have been properly trained to ensure safety.

Key Advantages

- Improved Safety Standards: Certified individuals are trained to recognize potential hazards and prevent unsafe practices, ensuring a safer environment for everyone involved.

- Enhanced Career Opportunities: Certification adds value to a resume, making candidates more attractive to potential employers and opening up job prospects in various sectors.

- Increased Consumer Confidence: Certification reassures customers that staff members are properly trained in handling and preventing risks, increasing trust in the services provided.

- Reduced Risk of Illness: Knowledge gained through certification helps reduce the likelihood of health-related incidents, protecting both consumers and workers from foodborne illnesses.

- Legal Compliance: In some regions, certification is required by law to ensure that businesses comply with health regulations. Being certified ensures that organizations meet necessary standards.

Additional Benefits for Businesses

- Better Reputation: Businesses with certified staff members are seen as responsible and reliable, boosting their reputation within the industry and community.

- Lower Costs: Certification can help businesses reduce waste and loss, as staff is trained to handle products efficiently and minimize errors.

- Compliance with Industry Regulations: Certification ensures that businesses stay up-to-date with the latest regulations and best practices, reducing the risk of fines and penalties.

In conclusion, becoming certified brings numerous advantages that not only enhance personal skills but also contribute to better overall operations and increased consumer trust. Whether for career growth or organizational improvement, certification is a valuable investment in both safety and success.

Frequently Asked Questions About Certification

Certification in health and safety standards is an essential qualification for those working in environments where proper handling practices are crucial. Below are some of the most common questions asked by individuals considering certification, along with clear answers to help guide the process.

What are the requirements for certification?

To obtain certification, individuals must complete a course that covers essential topics such as hygiene, safety protocols, and risk prevention. Depending on the jurisdiction, certain prerequisites may apply, such as a minimum age requirement or previous work experience in a related field. After completing the training, candidates are required to pass an exam to demonstrate their knowledge and understanding of the material.

How long is the certification valid?

The duration of certification validity varies depending on local regulations, but it typically lasts between 2 to 5 years. After the certification expires, individuals must complete a renewal process, which may involve retaking the exam or completing additional training courses to ensure they stay up to date with current standards and practices.

Can I take the exam online?

Yes, many certification programs offer online options, allowing individuals to take the course and exam remotely. Online courses often come with the convenience of flexible scheduling, enabling candidates to study at their own pace. However, some programs may require an in-person component for practical assessments or final exams.

What happens if I fail the exam?

If a candidate does not pass the exam on the first attempt, most programs offer the opportunity to retake the exam after a brief waiting period. Some organizations may also provide additional study materials or support to help candidates improve their knowledge before retaking the test. It’s important to review the specific policies of the certifying body to understand their retake procedures.

Is certification required by law?

In some regions, certification is mandatory for individuals working in certain industries, such as hospitality or healthcare. This requirement is typically enforced by local health departments or regulatory bodies. Even when not required by law, certification is often strongly recommended to ensure safe practices and enhance career opportunities in these fields.

How can certification benefit my career?

Obtaining certification can enhance your professional reputation, increase job prospects, and lead to higher earning potential. It demonstrates to employers that you have the necessary skills and knowledge to work safely and efficiently, which can give you a competitive edge in the job market. Additionally, many employers prefer or even require certified staff to ensure compliance with health and safety standards.

Certification is an investment in your professional development, providing both practical knowledge and valuable credentials that can open doors for career advancement and personal growth.

Next Steps After Passing the Exam

Successfully passing the exam is a significant achievement, but it marks only the beginning of the process. After completing the assessment, there are several key steps to take to ensure that you are fully certified and prepared to apply your knowledge in the workplace. Below is an outline of the steps you should follow after passing the test.

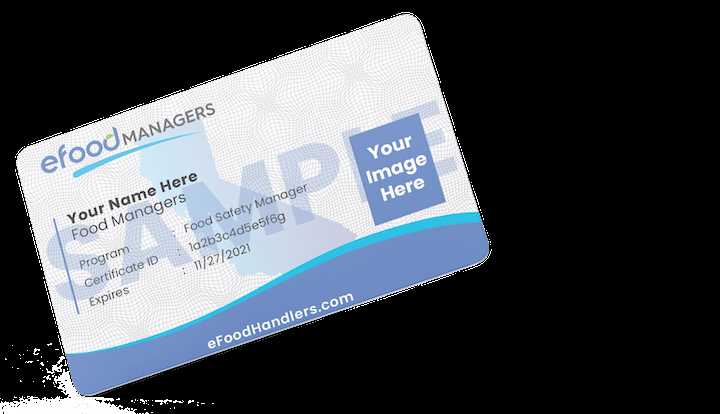

1. Receive Your Certification

Once you pass the exam, you will typically be issued a certificate or other official documentation verifying your accomplishment. This may be provided digitally or through physical mail, depending on the certification body. Be sure to keep a copy of your certificate for future reference and display it as required by your employer or local regulations.

2. Understand the Renewal Process

Certification is often valid for a limited period. It is important to familiarize yourself with the renewal requirements to ensure that you maintain your qualification. Some certifications require continuing education or periodic re-examination. Knowing the renewal timeline and process will help you stay current with industry standards.

3. Update Your Resume and Professional Profile

Now that you are officially certified, it’s time to update your resume or online professional profiles (such as LinkedIn). Highlight your new certification as a significant achievement, as it can enhance your employability and demonstrate your commitment to safety and professionalism.

4. Notify Your Employer

If your certification is job-related, inform your employer or manager. Many employers require proof of certification for certain positions. Additionally, your certification may make you eligible for promotions or other professional development opportunities within the company.

5. Stay Informed and Continue Learning

The field of safety regulations is constantly evolving, and staying informed about new guidelines, techniques, or best practices is essential. Look for opportunities to attend workshops, webinars, or additional training to enhance your knowledge and stay up to date with industry trends.

6. Begin Applying Your Knowledge

With your certification in hand, it’s time to apply the skills and knowledge you’ve gained. Whether you’re working in an environment where these practices are mandatory or simply want to promote best practices in your workplace, be proactive in implementing safety protocols and ensuring a healthy environment for everyone.

7. Monitor Your Certification Expiration Date

As you move forward, keep track of your certification expiration date. Ensure that you complete any necessary renewal steps in advance to avoid gaps in your certification status.

| Step | Action |

|---|---|

| Receive Certification | Obtain your official certificate and maintain a copy for future reference. |

| Understand Renewal | Learn about the certification renewal process and deadlines. |

| Update Professional Profiles | Update your resume and online profiles with your new certification. |

| Notify Employer | Inform your employer about your certification and its relevance to your role. |

| Continue Learning | Seek out opportunities to stay informed about the latest industry developments. |

| Apply Knowledge | Start using your certification to enhance safety practices at work. |

| Monitor Expiration Date | Track your certification’s expiration date and ensure timely renewal. |