Achieving certification in safe food handling practices is a vital step for anyone working in the culinary or hospitality industries. This certification ensures that individuals are equipped with the knowledge necessary to maintain hygiene and prevent contamination, contributing to a safer environment for both workers and customers.

Preparation for this type of certification involves understanding a variety of essential topics, from sanitation procedures to proper temperature control. Knowing these concepts can significantly reduce the risk of foodborne illnesses, making it crucial for all professionals in the industry to be well-prepared.

In this guide, we will explore the key areas that are typically tested, providing helpful insights and advice to increase your chances of success. By focusing on the most important concepts and practices, you can confidently approach the process of certification and demonstrate your expertise in maintaining safe and clean practices.

Food Handlers Exam Answers Guide

Successfully passing the certification process for safe workplace practices requires a solid understanding of several core concepts. This guide will focus on the critical areas you need to master to ensure you are fully prepared for the test, covering everything from sanitation protocols to effective risk management.

By focusing on the most common questions and areas of knowledge evaluated during the certification process, you can better anticipate what will be required. Preparation involves not only memorizing facts but also understanding how to apply safe practices in real-world situations.

In this section, we will break down key topics, providing helpful tips and strategies that will aid you in navigating the test with confidence. Emphasizing the importance of practical application, we will ensure that you are equipped with the necessary skills and knowledge to meet the requirements for achieving certification.

Understanding Food Safety Certification

Certification in safe practices is an essential qualification for individuals working in environments where hygiene and cleanliness are crucial. It ensures that workers have the knowledge and skills needed to prevent contamination and protect public health. The process involves learning about critical safety measures and how to implement them in various workplace settings.

This qualification not only confirms that a person understands proper sanitation techniques but also that they can effectively manage potential risks, such as the spread of pathogens or cross-contamination. Obtaining certification demonstrates a commitment to upholding industry standards and maintaining a safe environment for both workers and customers.

For anyone seeking this certification, it is important to grasp the main concepts tested during the process. A thorough understanding of key topics such as hygiene practices, temperature control, and proper handling techniques will be vital in ensuring success and meeting regulatory requirements.

Key Topics Covered in the Exam

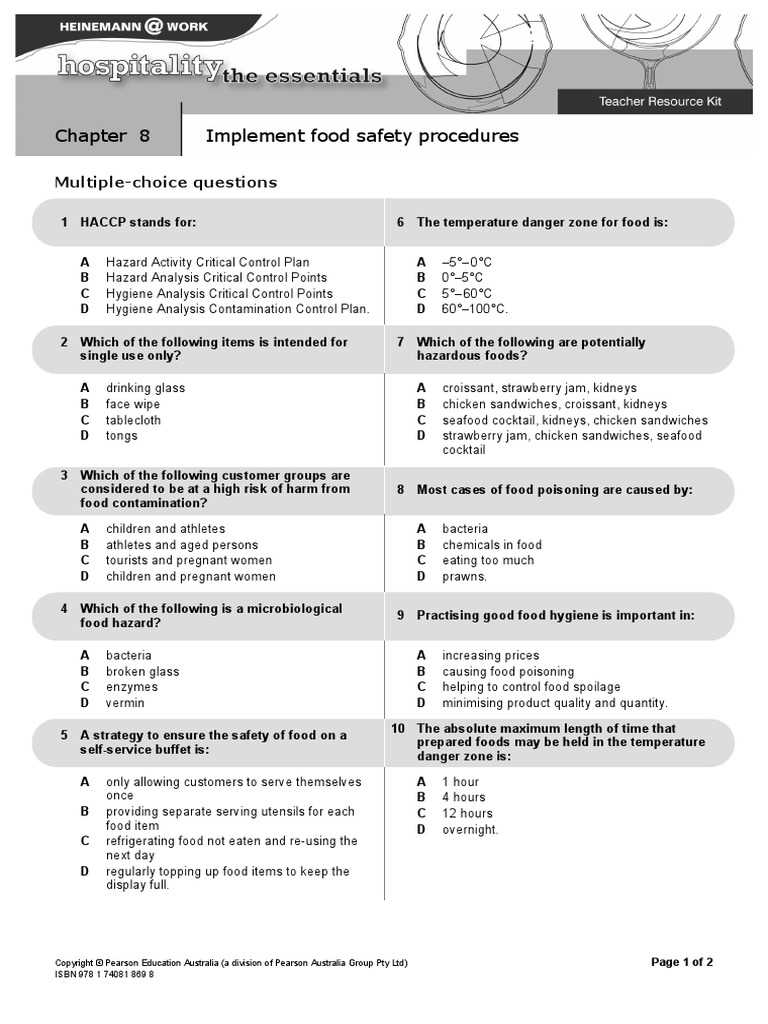

When preparing for a certification related to safe workplace practices, it’s essential to focus on the core topics typically assessed during the process. These areas of knowledge ensure that individuals can effectively manage hygiene, prevent contamination, and contribute to a safe environment in their respective industries. A solid understanding of these concepts is necessary for success.

Sanitation and Hygiene Practices

One of the most critical areas covered is sanitation. Understanding proper cleaning methods, personal hygiene requirements, and the maintenance of a clean workspace is vital. Candidates are tested on their ability to identify and manage risks associated with poor hygiene, as well as the importance of routine cleaning in preventing contamination.

Temperature Control and Safety Measures

Another key topic is the management of temperature in various environments. This includes understanding the safe temperature ranges for storing, cooking, and serving items. Knowledge of the potential hazards that arise from improper temperature control, such as the growth of harmful bacteria, is essential for maintaining safety and quality standards.

Essential Tips for Passing the Test

Successfully passing the certification process requires more than just memorizing facts; it involves understanding the core principles and being able to apply them effectively. In this section, we will provide key strategies that will help you prepare thoroughly and approach the test with confidence. These tips will guide you through the study process and help you manage your time and resources wisely.

Study and Review Key Concepts

Focusing your study efforts on the most relevant topics is crucial for success. Make sure to thoroughly review the core principles, such as hygiene practices, temperature control, and proper handling techniques. The more you understand how these concepts apply to real-life situations, the easier it will be to recall them during the certification process.

Practice with Mock Tests

Taking practice tests is one of the best ways to prepare. These tests simulate the actual experience, helping you familiarize yourself with the types of questions you might encounter. Practicing regularly will also improve your ability to manage time and reduce test anxiety.

| Tip | Description |

|---|---|

| Stay Organized | Keep your study materials well-organized and break them into manageable sections for easier review. |

| Understand Real-World Application | Focus on understanding how concepts apply to everyday situations in your work environment. |

| Review Regulations | Ensure that you are familiar with the latest regulations and guidelines relevant to safe practices. |

Common Mistakes to Avoid During the Exam

When preparing for a certification that tests knowledge of safety and best practices, it’s important to be aware of common mistakes that can hinder your success. Many individuals make errors that are easily avoidable with proper preparation and attention to detail. By recognizing these pitfalls, you can improve your chances of passing and ensure a smooth experience during the testing process.

One of the most frequent mistakes is rushing through questions without fully understanding what is being asked. It’s essential to take the time to read each question carefully and ensure that you fully grasp the context before selecting an answer. This approach helps avoid costly misunderstandings.

Another common error is neglecting to review study materials thoroughly. While it may seem tempting to focus only on the areas that seem most important, a well-rounded understanding of all topics covered in the test is necessary. Skipping over certain sections may lead to missing key questions related to those areas.

Finally, failing to manage your time effectively can result in unnecessary stress and rushed decisions. Ensure you allocate enough time to answer each question thoughtfully, and avoid spending too long on any single item. Prioritize accuracy and clarity over speed.

Foodborne Illnesses and Prevention Methods

Illnesses transmitted through improper handling or contamination of items can pose serious health risks. Preventing such illnesses is a primary concern in environments where safety and hygiene are critical. In this section, we will discuss the most common types of harmful microorganisms and the methods used to mitigate their spread. Understanding these threats and how to avoid them is essential for maintaining a safe environment.

Common Pathogens and Their Effects

There are several harmful microorganisms that can lead to serious health problems if not properly managed. These pathogens can be spread through improperly handled items, poor sanitation, or cross-contamination. Below are some of the most common offenders:

- Salmonella: A bacterium commonly found in raw meats and eggs, causing symptoms like nausea, vomiting, and diarrhea.

- Norovirus: Often associated with contaminated water or produce, leading to stomach cramps, vomiting, and diarrhea.

- E. coli: Found in undercooked meat, especially beef, and can cause severe gastrointestinal issues and kidney failure in extreme cases.

- Campylobacter: A bacterium frequently found in poultry, causing fever, cramps, and diarrhea.

Effective Prevention Methods

Implementing proper safety measures and hygiene practices is essential to preventing the spread of these harmful microorganisms. Below are key strategies to reduce the risk of contamination:

- Regular Hand Washing: Wash hands frequently, especially after handling raw items or using the restroom.

- Temperature Control: Ensure that items are stored and cooked at the correct temperatures to inhibit pathogen growth.

- Proper Sanitization: Regularly clean and disinfect surfaces, tools, and equipment to prevent cross-contamination.

- Separation of Raw and Ready-to-Eat Items: Keep raw materials separated from those that are ready to be consumed to avoid contamination.

- Thorough Cooking: Ensure that items, especially meats, are cooked thoroughly to kill any harmful bacteria or pathogens.

Proper Hygiene Practices for Food Handlers

Maintaining a high level of personal cleanliness and following proper hygiene protocols is essential for ensuring the safety and quality of items prepared for consumption. These practices help prevent contamination and the spread of harmful pathogens, which is crucial in any setting where the preparation or handling of consumables occurs. In this section, we will focus on key hygiene habits that must be adopted to maintain a safe working environment.

Key Hygiene Practices

Adhering to strict cleanliness guidelines not only helps prevent illness but also contributes to a positive reputation for businesses that prioritize safety. The following practices are crucial for all individuals involved in the preparation and handling of items:

- Frequent Hand Washing: Wash hands thoroughly with soap and water, especially before handling consumables, after using the restroom, or touching raw items.

- Use of Gloves: Wear gloves when handling ready-to-eat items, particularly if you have open wounds or sores.

- Clean Clothing: Always wear clean uniforms and aprons to prevent transferring dirt or germs from clothing to items.

- Personal Grooming: Keep hair tied back, and avoid wearing jewelry that could harbor bacteria or fall into prepared items.

- Proper Coughing and Sneezing Etiquette: Always cover your mouth and nose with a tissue or your elbow when coughing or sneezing to prevent airborne contamination.

Maintaining Clean Workspaces

It’s equally important to ensure that the environment in which items are prepared remains clean. Regular sanitation of all surfaces and tools is necessary to prevent cross-contamination and maintain overall hygiene standards.

- Sanitize Surfaces: Clean and disinfect countertops, cutting boards, and utensils regularly.

- Separate Equipment: Use different tools for raw and cooked items to avoid cross-contamination.

- Proper Waste Disposal: Ensure that trash is disposed of regularly and in appropriate containers to maintain cleanliness in the workspace.

The Importance of Temperature Control

Proper temperature management is a critical factor in maintaining safety and quality in any environment where consumables are prepared. Whether it’s keeping items cold or ensuring they are heated to the right temperature, temperature control plays a vital role in preventing the growth of harmful microorganisms that can cause illness. Understanding the correct temperature ranges for various processes is essential for anyone involved in handling perishable goods.

Prevention of Bacterial Growth

Many harmful bacteria thrive at certain temperatures, making it crucial to control the temperature of perishable items. Bacteria such as Salmonella, E. coli, and Listeria multiply rapidly when stored at unsafe temperatures, leading to potential contamination. Keeping items either below 40°F (4°C) or above 140°F (60°C) is essential to halt bacterial growth and ensure the safety of consumers.

Maintaining Quality and Freshness

In addition to safety concerns, temperature control also plays a key role in maintaining the freshness and flavor of items. Improper storage temperatures can cause items to spoil faster, leading to waste and a decline in the quality of the product. Ensuring items are kept at the correct temperature from storage to preparation is vital for preserving their integrity.

Key temperature control practices:

- Storage: Refrigerate perishable items immediately upon arrival and ensure temperatures stay below 40°F (4°C).

- Cooking: Heat items to the recommended internal temperature to kill harmful microorganisms. Use a food thermometer for accuracy.

- Holding: Keep hot items at or above 140°F (60°C) during display or serving to ensure they remain safe for consumption.

How to Handle Food Safely in the Workplace

In any setting where consumables are prepared or served, safety is of utmost importance. Proper techniques and best practices must be followed to ensure that the items handled remain safe for consumption and free from contamination. This section provides key guidelines for maintaining safety when working with edible products in the workplace, whether it involves preparation, storage, or serving.

Maintaining safety involves several key practices, including cleanliness, proper temperature control, and avoiding cross-contamination. By following these practices, potential risks can be minimized, and a safe environment can be maintained for both workers and consumers.

Essential Practices for Safe Handling

The following table outlines the essential steps to ensure proper safety when handling consumables:

| Practice | Description |

|---|---|

| Proper Hand Washing | Wash hands frequently with soap and water, especially after handling raw materials or using the restroom. |

| Correct Temperature Control | Ensure that items are stored, cooked, and served at the correct temperatures to prevent bacterial growth. |

| Separation of Items | Use separate equipment and surfaces for raw and cooked materials to avoid cross-contamination. |

| Regular Cleaning | Regularly clean all tools, surfaces, and utensils to prevent the spread of germs and harmful microorganisms. |

| Safe Storage | Store perishable items at appropriate temperatures and ensure they are covered to prevent exposure to contaminants. |

By following these practices consistently, individuals can maintain a safe environment and reduce the risk of contamination in the workplace.

Understanding Cross-Contamination Risks

Cross-contamination occurs when harmful microorganisms or allergens are transferred from one surface, object, or substance to another, leading to contamination of consumables. This is a major risk in environments where items are prepared, stored, or served. Understanding how contamination happens and the factors that contribute to it is crucial for maintaining a safe environment. The following section covers the primary sources and risks of cross-contamination and how they can be avoided.

Preventing cross-contamination is a fundamental aspect of maintaining safety and preventing illnesses caused by pathogens. It is essential to implement strategies that limit contact between raw and ready-to-eat items, along with proper sanitation of surfaces, tools, and equipment. By recognizing and addressing these risks, individuals can significantly reduce the chances of contamination in any setting.

Common Sources of Cross-Contamination

The table below outlines the most common ways cross-contamination occurs and the necessary precautions to prevent it:

| Source of Contamination | Risk and Prevention |

|---|---|

| Raw Materials | Raw items, especially meats, can carry harmful bacteria. Keep raw materials separate from ready-to-eat items, and use separate equipment for preparation. |

| Improper Hand Washing | Failure to wash hands thoroughly after handling raw items or using the restroom can spread germs. Always wash hands with soap and water for at least 20 seconds. |

| Shared Equipment | Using the same knives, cutting boards, or utensils for both raw and cooked items can lead to contamination. Clean and sanitize equipment after each use. |

| Unsanitized Surfaces | Countertops, tables, and other surfaces can harbor pathogens. Clean and disinfect surfaces regularly to reduce contamination risks. |

| Improper Storage | Storing items improperly, such as placing raw goods above ready-to-eat items, can lead to dripping and cross-contamination. Always store raw items at the bottom in refrigerators. |

By taking the necessary precautions and understanding how cross-contamination occurs, individuals can significantly reduce the risk of harmful pathogens affecting consumables. Consistent attention to hygiene and proper practices is key to preventing contamination in any environment.

The Role of Personal Protective Equipment

Personal protective equipment (PPE) plays a crucial role in maintaining hygiene and preventing contamination in environments where consumables are prepared, stored, or served. PPE helps safeguard both workers and customers from the risks associated with direct contact with potentially harmful substances. It serves as a barrier to prevent the transfer of pathogens, allergens, and other contaminants, ensuring that proper safety standards are upheld in the workplace.

The use of PPE is essential in reducing the risk of exposure to bacteria, viruses, and other harmful agents. Whether it’s gloves, aprons, hair coverings, or face masks, each piece of equipment serves a specific function in protecting both individuals and the items they work with. Consistent and correct use of PPE is one of the fundamental practices for promoting a safe working environment.

Key Types of Personal Protective Equipment

The following are the most commonly used types of PPE in environments where consumables are handled:

- Gloves: Protect hands from direct contact with raw materials, chemicals, and potential contaminants. Gloves should be changed frequently and disposed of properly.

- Aprons: Help protect clothing and skin from exposure to spills, stains, and contaminants. Aprons should be cleaned regularly to maintain their effectiveness.

- Hair Coverings: Prevent hair from falling into items and spreading contaminants. Hair nets or hats should be worn at all times when preparing or serving items.

- Face Masks: Protect against airborne contaminants and prevent the spread of germs through coughing or sneezing. Masks should be worn in high-risk areas and replaced when they become soiled.

Proper Use and Maintenance of PPE

Proper use and maintenance of personal protective equipment are vital for ensuring its effectiveness. It is essential to wear the correct type of PPE for each task, ensuring that it fits properly and provides adequate protection. PPE should be cleaned, stored, and disposed of according to the manufacturer’s guidelines to ensure optimal safety. Regular training and reminders about the proper use of PPE help ensure compliance and reduce the risk of contamination.

Exam Preparation: Study Resources and Materials

Preparing for certification assessments requires access to the right study materials and resources. These tools help individuals understand key concepts, practice essential skills, and reinforce knowledge necessary to succeed. A variety of study aids, such as guides, practice tests, and instructional videos, can be used to build confidence and ensure thorough understanding of the necessary topics. This section outlines some of the most useful study resources available for those looking to prepare effectively.

Essential Study Materials

To prepare thoroughly, it’s important to have a range of study materials that cover all the critical areas of the assessment. Some of the key resources include:

- Textbooks and Guides: Comprehensive books and manuals provide in-depth information on procedures, regulations, and best practices that are essential for success.

- Online Courses: Many platforms offer structured courses that allow for flexible learning at your own pace. These courses often include video lectures, quizzes, and practice scenarios.

- Flashcards: A quick and effective way to memorize key concepts and terminology. Flashcards are perfect for reinforcing learning and ensuring retention.

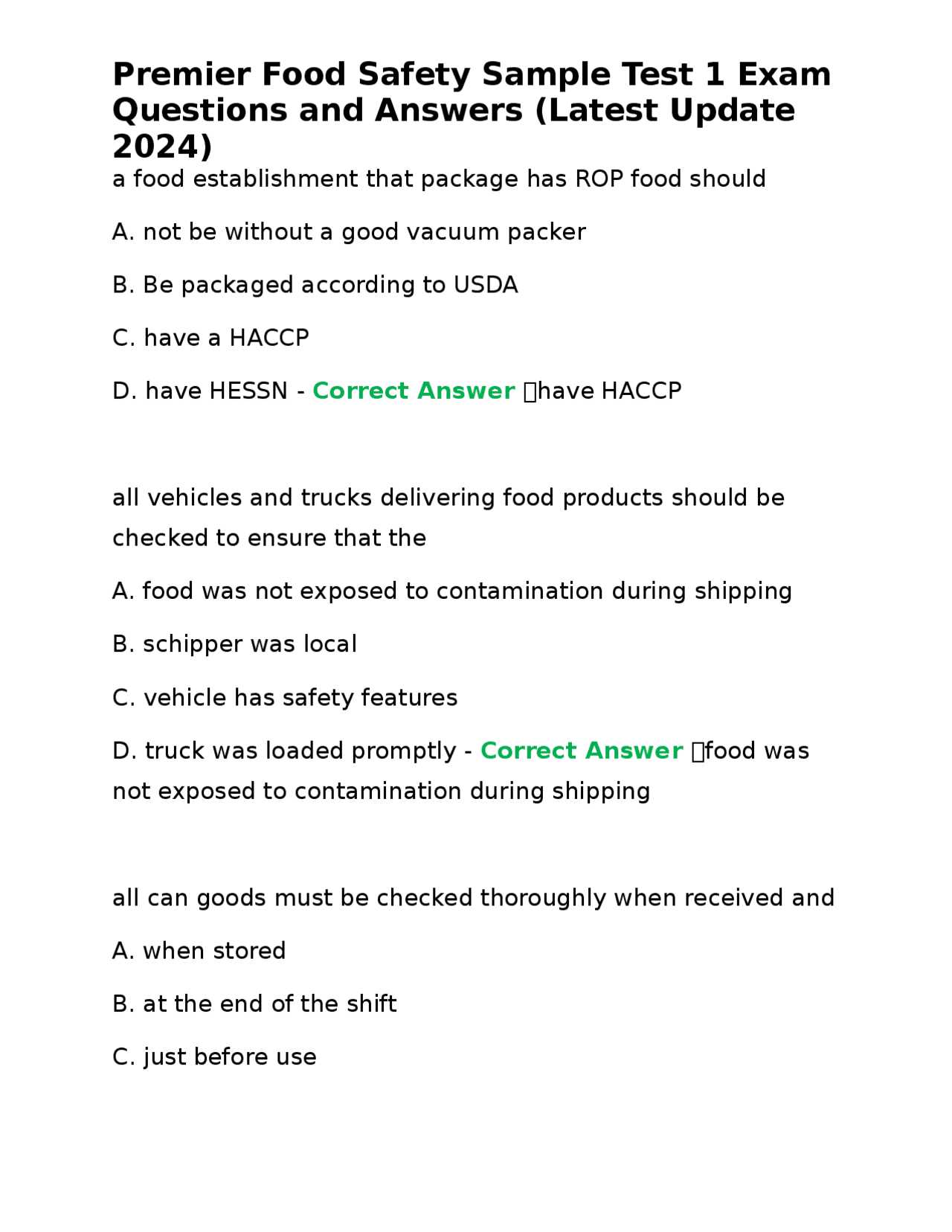

- Practice Tests: Simulated tests mirror the real assessment experience, allowing individuals to gauge their knowledge and identify areas that need improvement.

Online Resources and Support

In addition to physical study materials, there are several online resources that can enhance preparation:

- Interactive Websites: Websites that offer quizzes, sample questions, and learning modules can provide instant feedback and help reinforce what’s been learned.

- Discussion Forums: Online forums and groups allow individuals to ask questions, share study tips, and discuss complex topics with peers and experts.

- Webinars and Videos: Many educational websites and organizations offer free webinars and tutorial videos that break down challenging topics and provide additional explanations.

Using a combination of these resources will create a well-rounded study plan that improves understanding and ensures that all necessary knowledge is covered before taking the assessment.

How to Manage Allergens in Food

Managing allergens in the workplace is crucial for ensuring the safety of individuals who may have sensitivities or allergies to certain substances. Proper handling, storage, and preparation methods must be followed to avoid cross-contact and contamination. Understanding how to identify, manage, and communicate allergen information can prevent serious health risks and ensure a safe environment for everyone involved.

Key Steps to Prevent Allergen Cross-Contact

To reduce the risk of cross-contact, it’s essential to implement proper procedures at every stage of the preparation process. The following steps are fundamental to managing allergens effectively:

- Separate Storage: Keep allergenic ingredients in separate containers and storage areas to prevent them from coming into contact with other items. Clearly label all allergenic substances to ensure easy identification.

- Designate Equipment: Use separate utensils, cutting boards, and equipment for allergen-containing ingredients. If shared equipment must be used, ensure thorough cleaning and sanitization between uses.

- Proper Cleaning: Regularly clean and sanitize surfaces, equipment, and utensils that may have come into contact with allergens. This is essential for minimizing the risk of cross-contamination.

- Employee Training: All staff members should be trained on the importance of allergen management and how to recognize and handle potential allergens in the workplace.

Communication and Labeling

Clear communication is essential when it comes to allergens. Whether it’s through written information, verbal communication, or labeling, ensuring that staff and customers are aware of potential allergens is key to preventing accidents:

- Ingredient Labeling: All products containing allergens should be labeled clearly, both on packaging and in any menu or serving information provided to customers.

- Informing Customers: When serving prepared items, be sure to provide customers with accurate allergen information, including potential sources of allergens in their meals.

- Cross-Contamination Warnings: Clearly communicate to both staff and customers any potential risks of cross-contamination, particularly if certain allergens are present in the same facility.

By following these practices, workplaces can reduce the risk of allergen-related incidents and create a safer environment for both staff and consumers.

What to Expect on Exam Day

On the day of your certification assessment, it’s essential to be well-prepared and understand the structure of the process. This day can be both exciting and stressful, so having a clear idea of what will happen can help ease any anxiety and ensure you approach the task confidently. Being familiar with the format, environment, and expectations can make the entire experience smoother and more manageable.

Before the Assessment

Prior to starting, make sure to arrive early to allow yourself plenty of time to settle in and review any last-minute notes. Here are some tips to keep in mind:

- Bring Necessary Identification: Ensure you have a valid ID or any other required documents to verify your identity.

- Review Key Concepts: Take a few moments to review any key concepts or materials you’ve studied. Don’t cram; just go over important points to refresh your memory.

- Check for Instructions: Listen carefully to any instructions given by the proctor or administrator, including how the assessment will be conducted and how much time you have to complete it.

During the Assessment

As you begin the assessment, maintain focus and pace yourself throughout the process. Here’s what to expect:

- Multiple-Choice Questions: Most assessments consist of multiple-choice questions designed to test your knowledge on key topics. Take your time to read each question carefully before selecting your answer.

- Time Limit: Keep track of time, but don’t rush. If you get stuck on a question, it’s okay to move on and return to it later.

- Practical Component (if applicable): If the assessment includes a practical component, make sure to follow all instructions precisely and demonstrate proper techniques.

By understanding what to expect and being mentally prepared, you can approach your certification process with confidence and set yourself up for success.

Post-Exam Steps for Certification

After completing your assessment, there are several key steps to follow in order to finalize your certification process. Understanding what comes next ensures you stay on track and can confidently receive your qualification. These steps typically involve waiting for your results, understanding the feedback, and preparing for any necessary follow-up actions.

Reviewing Your Results

Once the assessment is completed, you will typically need to wait for your results. The timeline can vary, but here’s what you should expect:

- Receiving Your Score: Depending on the assessment method, results may be available immediately or take a few days to process. Make sure you are aware of the timeline provided by the testing authority.

- Understanding the Outcome: If you have passed, you will likely be notified about your certification status and when you will receive your official document. If you did not pass, the results will typically include feedback on areas to improve.

What to Do After Receiving Results

If you have successfully passed the assessment, congratulations! Here are the next steps to complete your certification process:

- Receive Your Certification: After passing, you will be issued a certification, either digitally or as a physical document. Keep it in a safe place and use it for professional purposes.

- Celebrate and Stay Updated: Take pride in your accomplishment, but remember that certifications often need to be renewed periodically. Keep track of renewal dates and any continuing education requirements.

If you did not pass, it’s important to approach the situation constructively. Consider the following:

- Review Your Mistakes: Look closely at the feedback and focus on the areas where you struggled. Use this as a learning opportunity to strengthen your understanding.

- Retake the Assessment: Many testing organizations allow you to retake the assessment after a waiting period. Prepare accordingly, using additional study materials or practice exams.

By following these steps, you can ensure that you complete the certification process effectively, whether you pass on your first attempt or need to retake the assessment.

Maintaining Your Food Handler Certification

Once you’ve earned your qualification, it’s essential to ensure that it remains valid and up-to-date. This process involves meeting certain requirements, such as completing refresher courses, staying informed about industry changes, and renewing your certification as needed. Keeping your credentials active demonstrates your ongoing commitment to maintaining high standards in your role.

Renewal Requirements

Certifications typically have an expiration date, and it’s important to renew them before they lapse. Here’s how to stay on top of your renewal process:

- Know the Expiry Date: Mark the expiration date on your calendar and begin the renewal process well in advance to avoid any gaps in certification.

- Complete Continuing Education: Some certifications require professionals to complete additional training or courses to ensure they stay current with best practices.

- Submit Your Renewal Application: This usually involves submitting proof of continued education, payment of renewal fees, and sometimes passing a brief assessment.

Staying Informed and Compliant

To maintain your certification effectively, it’s important to stay informed about industry changes and new regulations:

- Attend Refresher Courses: Many organizations offer refresher courses that provide updates on best practices and new safety standards. This is a great way to stay ahead.

- Read Industry Guidelines: Keep up with new research and guidelines related to safety and health practices in your field. Staying informed helps you provide the best service and reduces the risk of errors.

By following these steps, you can ensure that your certification remains valid, helping you to stay competitive and compliant in your profession.