When it comes to operating heavy machinery, thorough knowledge and practical skills are essential. Ensuring that you are fully prepared for the assessment process is key to achieving success and demonstrating competence. The process of gaining official approval to handle industrial equipment involves both theoretical understanding and hands-on experience, which must be mastered to meet industry standards.

Mastering safety protocols and understanding operational guidelines are critical components of the assessment. As part of the preparation, familiarizing oneself with the key aspects of handling machinery, from routine inspections to proper usage in various environments, is vital. Successful completion of the evaluation reflects a commitment to professionalism and safety in the workplace.

In this guide, we’ll explore the important steps needed to prepare for the challenge. From understanding common questions to learning about the structure of the evaluation, we provide a roadmap to help you confidently navigate the process and secure the necessary qualifications for working with industrial equipment.

Forklift Operator Final Exam & Certification Answers

Preparation for the necessary assessment to handle industrial machinery involves more than just memorizing facts. It’s about understanding key concepts related to safety, equipment handling, and compliance with regulations. A structured approach to the study process ensures that you are ready for both theoretical and practical components of the qualification test. Knowing what to expect and how to approach various topics will help boost your confidence and improve your performance during the evaluation.

During the qualification procedure, you will encounter a range of questions designed to test your knowledge of machine handling, safety procedures, and industry standards. Below is a table that highlights common areas of focus and the types of questions you may encounter in the assessment process:

| Topic | Key Areas of Focus |

|---|---|

| Safety Protocols | Handling hazards, emergency procedures, and personal protective equipment |

| Machine Operation | Proper usage, inspection, and maintenance procedures |

| Workplace Regulations | Compliance with OSHA standards, load capacity, and site-specific rules |

| Environment Awareness | Understanding surroundings, pedestrian safety, and equipment positioning |

| Problem Solving | Identifying issues with equipment and addressing common operational challenges |

Being well-prepared means you can approach each of these topics with a clear understanding, helping you pass the evaluation with ease and ensuring you are ready for the responsibilities of operating industrial machinery.

Overview of Forklift Operator Certification

Obtaining official qualification to handle industrial machinery is an essential step in ensuring both personal and workplace safety. The process involves demonstrating proficiency in equipment handling, safety measures, and compliance with industry regulations. This qualification not only certifies your capability to manage machinery effectively but also signifies your commitment to maintaining high operational standards in various environments.

The qualification procedure typically includes both theoretical knowledge and practical skills assessments. Theoretical knowledge covers important topics such as safety protocols, machine maintenance, and legal requirements. Practical assessments test how well you can apply these principles in real-world scenarios, ensuring you can operate equipment safely and efficiently under various conditions.

Once completed, the qualification serves as proof of your expertise and provides employers with confidence that you can safely handle equipment while adhering to best practices. This formal recognition is essential for anyone aiming to work in environments where industrial machinery is a primary tool, enhancing both career prospects and workplace safety.

Key Concepts for the Forklift Test

To succeed in the qualification process, it is essential to grasp several core principles related to the safe and efficient use of industrial machinery. Mastery of these concepts ensures you are prepared to handle different situations, from routine operations to emergency scenarios, with confidence and competence. This section highlights the main topics you should focus on during your preparation.

Safety Protocols and Procedures

Understanding and applying safety protocols is a fundamental aspect of the qualification process. This includes knowing how to properly inspect equipment before use, identifying potential hazards, and following the correct procedures for preventing accidents. Personal protective equipment (PPE), emergency response protocols, and situational awareness are all critical areas to focus on.

Equipment Handling and Maintenance

Another key concept involves being able to operate and maintain machinery safely. This includes understanding the operational controls, load limits, and proper positioning of the equipment in different environments. Additionally, performing routine maintenance checks to ensure that all components are functioning correctly is vital for avoiding malfunctions and ensuring longevity. Knowing how to handle a variety of machinery under different working conditions is essential to passing the qualification.

Understanding Safety Protocols for Forklifts

Safety is the cornerstone of effective equipment handling. A comprehensive understanding of safety measures ensures that operators can avoid accidents, protect themselves and others, and maintain a safe working environment. Familiarity with the key safety guidelines is essential for anyone working with industrial machinery, as it minimizes the risk of injury and damage in the workplace.

These protocols cover a broad range of practices, from performing pre-operation checks to knowing how to respond in emergency situations. Critical components include securing the area around the equipment, wearing the appropriate protective gear, and ensuring that the machinery is in optimal condition before use. Safety measures also extend to proper load handling and the ability to navigate through different environments, including high-traffic areas.

Adhering to safety protocols not only ensures compliance with regulations but also promotes long-term operational efficiency. By following these guidelines, workers can reduce the likelihood of accidents, extend the lifespan of the equipment, and contribute to the overall safety culture within the workplace.

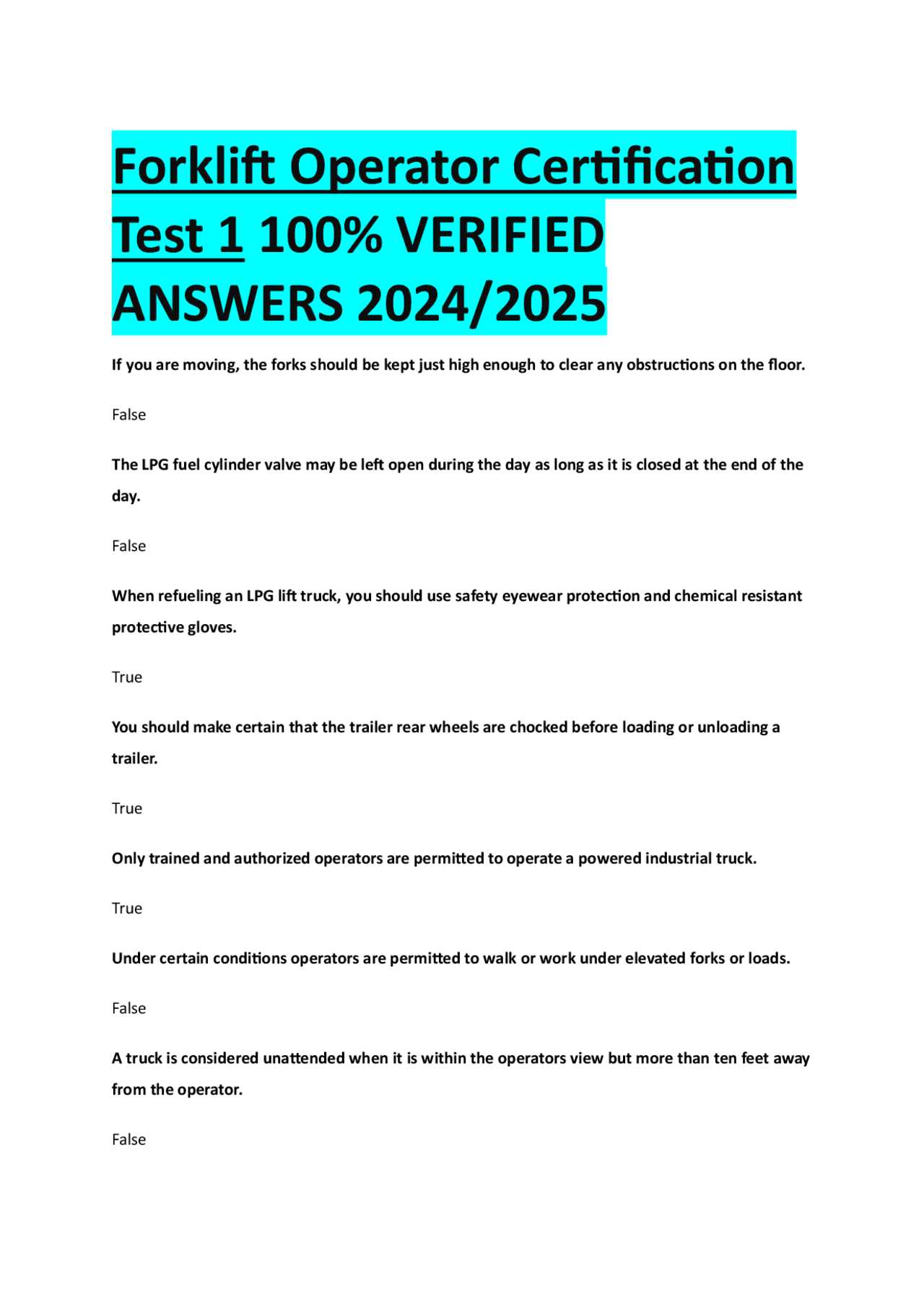

Commonly Asked Questions on the Exam

When preparing for the qualification process, it is helpful to anticipate the types of questions that will be asked. These questions are designed to assess your understanding of essential topics such as safety, equipment handling, and operational procedures. Familiarizing yourself with the most commonly asked questions can improve your confidence and help you focus your study efforts on the areas that matter most.

Below are some of the key areas and example questions that are often encountered during the assessment:

- Safety Measures: What are the key safety protocols to follow before operating machinery?

- Operational Procedures: How do you properly inspect equipment before use?

- Load Handling: What are the weight limits for different types of equipment?

- Workplace Awareness: How do you ensure the area around the equipment is safe for operation?

- Emergency Response: What steps should you take in the event of a malfunction or emergency situation?

These questions focus on ensuring that you are well-prepared to handle both the theoretical and practical aspects of the process. By understanding these core topics, you will be able to answer with accuracy and demonstrate your ability to safely operate machinery in various scenarios.

Preparing for Your Forklift Final Exam

Successfully completing the qualification process requires a focused approach to preparation. It is essential to understand the key areas that will be assessed and ensure that you have a solid grasp of both theoretical knowledge and practical skills. Proper preparation not only improves your chances of passing but also enhances your ability to perform safely and efficiently in the workplace.

To begin your preparation, review all relevant safety protocols, operational procedures, and maintenance practices. This knowledge forms the foundation of the assessment. In addition, practical experience with the machinery is crucial, as it allows you to apply what you have learned in real-world scenarios. The combination of study and hands-on practice will help you feel confident when the time comes for the evaluation.

Utilizing study guides, practice tests, and additional resources can also be beneficial. These materials can help familiarize you with the structure of the test and the types of questions that may arise. By breaking down the preparation into manageable steps, you can focus on each key area without feeling overwhelmed.

Required Skills for Forklift Certification

Achieving qualification to handle industrial machinery requires a combination of theoretical knowledge and practical skills. It is essential to master a variety of competencies that ensure safe and efficient equipment operation. These skills not only help you pass the assessment but also enable you to work confidently in diverse environments where safety and precision are paramount.

Key Skills for Safe Machinery Operation

The following skills are crucial for anyone aiming to operate machinery effectively:

- Safety Awareness: Understanding and applying safety protocols to minimize risks and prevent accidents.

- Equipment Handling: Knowing how to operate machinery properly, including lifting, lowering, and transporting loads.

- Load Management: Assessing and adhering to weight limits to ensure stability and balance during operation.

- Inspection and Maintenance: Regularly checking equipment for damage, ensuring that it is in safe working condition, and performing minor repairs when needed.

Practical Skills for Workplace Efficiency

In addition to basic handling, there are several practical skills that enhance workplace efficiency:

- Spatial Awareness: Navigating tight spaces and understanding the best ways to position equipment in various work environments.

- Communication: Effectively communicating with coworkers to ensure safe coordination around machinery.

- Problem-Solving: Quickly identifying operational issues and troubleshooting potential malfunctions.

- Adaptability: Adjusting to different work conditions and equipment types as needed.

Mastering these essential skills is key to successfully completing the qualification process and ensuring a high level of competency in the workplace.

Types of Forklift Operators’ Exams

There are various types of assessments designed to evaluate the competence of individuals working with industrial machinery. Each assessment is structured to test different aspects of machinery handling, safety protocols, and workplace practices. These evaluations typically consist of both written and practical components, tailored to the specific needs of different job roles and environments.

Written Assessments

The written part of the evaluation primarily focuses on theoretical knowledge. It tests your understanding of safety standards, operational procedures, and legal requirements related to machinery use. The written assessment generally includes multiple-choice, true/false, and short-answer questions to evaluate your comprehension of critical concepts.

Practical Assessments

Practical assessments are conducted to evaluate your hands-on ability to operate machinery in real-world scenarios. This section typically involves performing tasks such as loading, unloading, and maneuvering in tight spaces. Assessors will observe your ability to apply theoretical knowledge safely while demonstrating control over the equipment.

Below is a table summarizing the key components of both types of assessments:

| Type of Assessment | Focus Area | Evaluation Method |

|---|---|---|

| Written Assessment | Theoretical knowledge on safety, procedures, and regulations | Multiple-choice, true/false, short-answer questions |

| Practical Assessment | Hands-on operation and safety practices | Task performance under supervision in a controlled environment |

Both types of assessments are critical in ensuring that individuals are well-prepared to operate machinery safely and efficiently in a professional setting. A successful completion of these evaluations demonstrates a thorough understanding of essential skills and knowledge necessary for the job.

Study Tips for Forklift Exam Success

Preparing for the qualification assessment requires a strategic approach. To improve your chances of success, it’s essential to focus on key areas that will be evaluated during the process. Developing a study routine that balances theoretical knowledge with practical skills will help you feel more confident and well-prepared when it’s time to undergo the assessment.

One of the best ways to prepare is by breaking down the material into smaller, manageable sections. This allows you to focus on one area at a time, reinforcing what you’ve learned before moving on to the next topic. Consistent review and practice are key to mastering both the theoretical and hands-on components of the process.

Study Techniques for Effective Learning

Here are some tips that can help you prepare more effectively:

| Study Method | How it Helps |

|---|---|

| Use Study Guides | Study guides help organize important concepts and can highlight areas you may have overlooked. |

| Practice with Mock Tests | Taking practice tests helps familiarize you with question formats and improves recall under pressure. |

| Hands-On Practice | Applying what you’ve learned in real-world scenarios helps reinforce your practical skills and boosts confidence. |

| Group Study Sessions | Collaborating with others allows for the exchange of tips and insights, which can enhance your understanding of challenging topics. |

| Review Safety Protocols | Focusing on safety regulations and best practices is crucial, as these are often a major component of the evaluation. |

By incorporating these methods into your study routine, you’ll be better prepared to successfully complete the qualification process. The more familiar you are with both the theoretical concepts and the practical skills required, the more confident you will be on the day of the assessment.

Practical Knowledge for Forklift Certification

Acquiring hands-on experience is a crucial part of preparing for the qualification process. Practical knowledge goes beyond theoretical understanding; it involves applying what you’ve learned in real-world situations. Mastering the skills required to handle machinery safely and effectively is vital for success in both everyday tasks and formal evaluations.

In order to be fully prepared, it’s important to be proficient in equipment handling, as well as in the safety protocols and maintenance practices that ensure optimal performance. Gaining familiarity with various operational techniques, such as loading and unloading, maneuvering in tight spaces, and assessing stability, will strengthen your ability to work confidently and efficiently.

Key aspects of practical knowledge include:

- Equipment Familiarity: Knowing how to operate different types of machinery safely and effectively.

- Safety Protocols: Being able to apply all necessary safety measures to prevent accidents and injuries.

- Load Handling: Understanding how to properly manage loads, ensuring they are balanced and secure before moving them.

- Inspection and Maintenance: Being able to perform routine checks to ensure machinery is in good working condition and identifying potential issues before they arise.

- Communication Skills: Effectively coordinating with team members to maintain a safe and productive work environment.

By focusing on these key areas, you can ensure you are well-prepared for the hands-on portion of the qualification process. Gaining practical experience will not only help you pass assessments but also equip you with the skills necessary to excel in your daily work tasks.

Forklift Operator Certification Test Format

The structure of the qualification assessment is designed to test both theoretical knowledge and practical skills. Understanding the format of the evaluation can help you better prepare and reduce anxiety. The process typically involves two main components: a written test to assess your knowledge of safety protocols and operational procedures, and a practical assessment to evaluate your ability to handle machinery in real-world situations.

The written portion generally consists of multiple-choice questions, true/false statements, and short-answer sections. These questions cover various topics, including safety regulations, machine operation guidelines, and maintenance procedures. The goal is to ensure that you have a strong grasp of the rules and best practices that are essential for operating equipment safely.

The practical part of the assessment is designed to evaluate how well you can apply your knowledge in a real-world environment. During this portion, you will be asked to demonstrate your ability to safely operate machinery, perform tasks such as loading and unloading, and follow safety protocols while working in a controlled setting. Assessors will observe your technique, control, and ability to work efficiently and safely.

By understanding the structure of the test, you can allocate your study time accordingly and focus on both theory and hands-on practice to ensure a successful outcome.

What to Expect During the Exam

When it comes time to undergo the qualification process, understanding what to expect can make a significant difference in your performance. The assessment typically consists of two parts: a theoretical portion and a practical evaluation. Both are designed to assess your readiness to safely handle machinery and apply the necessary safety procedures.

Before the process begins, you will likely be given an overview of what’s to come. This could include a briefing on the rules and the format of the test, as well as any specific instructions for the hands-on portion. It’s important to stay calm and listen carefully, as the information provided can help guide you through each step.

Theoretical Portion:

- You’ll be asked a series of questions that will test your knowledge on safety practices, machine operation, and routine maintenance.

- Questions may be in multiple-choice, true/false, or short-answer format.

- Take your time to read each question carefully and answer based on the knowledge you’ve gained during your preparation.

Practical Evaluation:

- You will be asked to demonstrate your ability to operate equipment in a controlled environment.

- Expect to perform tasks such as loading, unloading, and maneuvering, all while adhering to safety protocols.

- Assessors will evaluate your technique, control, and decision-making in real-time scenarios.

- Stay focused and approach each task with caution, as this part of the evaluation emphasizes safety and efficiency.

By familiarizing yourself with what to expect, you can reduce anxiety and increase your chances of success. Be sure to review key concepts and practice hands-on skills ahead of time, so you’re well-prepared for both sections of the process.

Top Resources for Studying Forklift Safety

When preparing for a qualification that involves machinery handling, understanding safety protocols is crucial. There are many valuable resources available that can help enhance your knowledge and ensure you are well-prepared for the assessment. These resources can range from official manuals and training courses to online platforms and safety guides.

Official Safety Guidelines and Manuals

One of the most reliable sources for studying safety procedures is through official documents and industry-recognized safety manuals. These materials often provide comprehensive information on essential protocols, operational guidelines, and best practices for safe machinery use.

- OSHA Guidelines: The Occupational Safety and Health Administration provides in-depth guidelines on safety standards that are widely used in many industries.

- Manufacturer Manuals: Equipment manufacturers offer detailed safety instructions and user manuals tailored to specific machinery.

- Industry Safety Standards: Many organizations publish standards that provide guidelines for safe operation and risk prevention.

Online Training and Interactive Courses

For those who prefer a more interactive or self-paced learning approach, online training programs can be extremely helpful. These platforms provide virtual courses, videos, and quizzes that allow you to study at your own pace and test your knowledge along the way.

- Online Training Platforms: Websites like Udemy, Coursera, and LinkedIn Learning offer courses on machinery safety and operational protocols.

- YouTube Tutorials: Many instructors and organizations upload videos demonstrating safety practices and equipment handling techniques.

- Interactive Webinars: Some safety organizations host live webinars that offer insights into the latest safety standards and operational techniques.

By utilizing a combination of these resources, you can gain a well-rounded understanding of safety practices and improve your readiness for any qualification process. Make sure to incorporate both theoretical study and practical training for a comprehensive approach to safety.

How to Handle Forklift Exam Questions

Approaching a qualification test that assesses your knowledge of machinery handling requires careful preparation and the right mindset. Knowing how to effectively answer the questions and manage your time is essential to success. It’s not just about memorizing facts; it’s about applying what you’ve learned to various scenarios that might arise during the assessment.

To tackle these questions confidently, it’s crucial to understand the key principles involved in safe and efficient machine use. Many questions will focus on your understanding of safety protocols, best practices, and risk prevention strategies. Read each question thoroughly before answering to ensure you fully understand what’s being asked.

1. Read Questions Carefully

Take your time to read each question carefully, ensuring that you comprehend the core of what is being asked. Many questions will be phrased in a way that requires you to choose the most appropriate response based on the context provided.

- Focus on Keywords: Look for specific terms or phrases that indicate the core concept of the question, such as “safety,” “procedure,” or “risk management.”

- Understand the Scenario: Many questions will present you with a scenario–consider the circumstances thoroughly before making your decision.

- Avoid Overthinking: Don’t second-guess your initial response unless you’re sure you misunderstood the question.

2. Eliminate Incorrect Choices

If the assessment includes multiple-choice questions, an effective strategy is to eliminate the options that are clearly incorrect. This increases your chances of selecting the right answer even if you’re unsure about the specifics.

- Use Logic: Eliminate choices that contradict established safety standards or best practices.

- Consider Practical Applications: Think about how the scenario would unfold in a real-world situation, and choose the response that aligns with common sense and safety protocols.

With these strategies in mind, you’ll be better equipped to answer questions with confidence and precision. Understanding the material, reading questions carefully, and using logical deduction will help you achieve success in your qualification process.

Importance of Certification for Employers

For employers, ensuring that their staff possess the necessary qualifications to operate machinery safely is crucial not only for maintaining a secure work environment but also for complying with legal requirements. Certification programs serve as a benchmark, confirming that workers are equipped with the right skills to handle equipment safely and effectively. This process is vital for preventing workplace accidents, reducing liabilities, and improving operational efficiency.

1. Enhancing Workplace Safety

One of the primary benefits of having qualified personnel is the improved safety it brings to the workplace. Certified individuals are trained to recognize hazards and follow proper safety protocols, minimizing the risk of accidents and injuries. Employers who invest in proper training and qualification ensure that their team is well-prepared to handle potentially dangerous situations.

- Reduced Injury Risk: Employees with the proper knowledge are less likely to make unsafe decisions that could lead to accidents.

- Better Incident Response: Certified workers can respond more effectively to emergencies, reducing the impact of accidents.

- Compliance with Regulations: Certification ensures that businesses are in line with safety standards set by regulatory bodies.

2. Boosting Productivity and Efficiency

Well-trained employees tend to work more efficiently, as they understand how to use equipment properly and avoid delays caused by operational mistakes. Employers benefit from a more streamlined process, where tasks are completed faster and with fewer errors.

- Faster Task Completion: Knowledgeable workers are able to complete their responsibilities with greater speed and accuracy.

- Higher Productivity: Skilled workers can perform tasks more efficiently, allowing businesses to maximize output.

- Reduced Downtime: Proper training helps prevent equipment damage, minimizing the downtime associated with repairs.

By prioritizing the qualification of their employees, employers are not only improving safety and productivity but also reinforcing their commitment to creating a responsible, professional work environment. Certification provides employers with peace of mind, knowing that their team has the expertise required to meet industry standards and maintain operational excellence.

Tips for Managing Test Stress

Tests can be a stressful experience, especially when they are tied to important qualifications. It’s normal to feel anxious, but there are effective ways to manage stress and perform at your best. By preparing mentally and physically, you can reduce nervousness and approach the assessment with confidence. The following strategies will help you stay calm and focused throughout the process.

1. Prepare Well in Advance

One of the most effective ways to reduce test-related anxiety is through thorough preparation. The more you practice and familiarize yourself with the material, the more confident you’ll feel on test day. Review key concepts regularly, and don’t wait until the last minute to study.

- Study Consistently: Break your study sessions into manageable chunks over a longer period rather than cramming all at once.

- Use Practice Tests: Taking mock tests can help you get comfortable with the format and identify areas where you need improvement.

- Review Key Safety Procedures: Safety protocols are often a major focus, so ensure you understand these concepts thoroughly.

2. Develop Relaxation Techniques

Managing stress during the test is just as important as preparing for it. When you feel anxious, it’s easy to lose focus or make mistakes. Implementing relaxation techniques can help calm your nerves and clear your mind.

- Deep Breathing: Practice slow, deep breaths to help calm your body and mind before the test begins.

- Visualization: Take a few moments to imagine yourself succeeding, which can help build positive confidence.

- Stay Present: Focus on the question at hand rather than worrying about the entire test. Take it one step at a time.

Remember, feeling a bit of stress is natural, but managing it is key to success. With preparation, practice, and relaxation, you can approach the test with a calm and confident mindset, increasing your chances of success.

How to Pass the Certification Assessment

Successfully completing the required assessment for your qualifications involves more than just memorizing information. It requires understanding key concepts, practicing skills, and staying focused throughout the process. By using the right strategies and preparing effectively, you can improve your chances of passing the test with confidence. Below are some essential tips to guide you through the process and ensure you are fully prepared.

1. Study the Core Concepts Thoroughly

Before taking the assessment, ensure you have a strong grasp of the fundamental principles. This includes safety guidelines, operational techniques, and proper equipment handling. Reviewing these key areas will help you navigate the test with ease.

| Key Areas to Study | Description |

|---|---|

| Safety Protocols | Understanding the correct safety measures is essential. This includes personal protective equipment (PPE), hazard identification, and emergency procedures. |

| Operational Techniques | Know how to operate the machinery effectively, including loading, unloading, and stacking procedures. |

| Maintenance Procedures | Familiarize yourself with routine checks and basic maintenance tasks to ensure smooth operation. |

2. Practice with Simulations

Familiarize yourself with the testing format by practicing with simulations. These mock tests or practical exercises will help you become more comfortable with the types of questions and scenarios you may encounter. Practicing under timed conditions will also help you manage your time more effectively during the actual assessment.

Make sure to review any feedback from these practice sessions, as this will help you identify areas for improvement before taking the actual test. Keep a calm and methodical approach during your practice sessions, and it will pay off when you take the real test.

3. Stay Calm and Confident

Test anxiety can impact your performance, so it’s important to stay calm and confident. Arrive well-rested and prepared, and focus on the task at hand. Trust in your preparation, and take the test one question at a time. If you encounter a difficult question, don’t panic–take a moment to think it through, and move on if needed.

With consistent preparation, practice, and a focused mindset, you’ll be ready to succeed in the assessment and earn your qualification.

Post-Certification: Next Steps for Professionals

Once you have successfully completed the qualification process, it’s important to focus on the next steps to continue growing professionally. Achieving this milestone opens the door to new responsibilities, opportunities, and ongoing skill development. To ensure long-term success, follow these key steps after obtaining your qualification.

1. Maintain Your Skills and Knowledge

Continuous learning is vital to staying up-to-date with industry best practices. Even after receiving your qualification, regular practice and study will ensure that you remain proficient and efficient in your duties. Consider the following ways to maintain your skills:

- Participate in refresher courses or workshops to stay updated on new technologies and safety regulations.

- Review safety protocols and operational guidelines to prevent complacency.

- Seek mentorship or peer feedback to learn from others in the field.

2. Stay Informed on Safety Regulations

Workplace safety is paramount, and regulations are constantly evolving. It is crucial to remain informed about the latest safety standards and compliance requirements. This can help you avoid accidents and contribute to a safer work environment. Steps to stay updated include:

- Subscribe to industry newsletters and safety bulletins.

- Attend safety meetings or conferences to learn about the latest trends and regulations.

- Keep your safety knowledge up to date through regular training sessions provided by your employer or external organizations.

3. Pursue Advanced Qualifications

If you are looking to advance your career, consider pursuing additional qualifications or specializations. Many professionals choose to develop expertise in areas such as advanced equipment handling, supervisory roles, or specific industries. Options include:

- Advanced training programs for specialized equipment or machinery.

- Leadership or management courses if you aspire to supervisory positions.

- Certifications in areas like logistics, warehousing, or transportation management.

4. Network and Explore Career Opportunities

Networking with others in the industry can help you discover new career opportunities and stay connected with trends and job openings. Leverage professional networks, job fairs, and online communities to expand your career options. Additionally, consider:

- Joining professional organizations to connect with other qualified individuals.

- Exploring career advancement opportunities within your current organization.

- Building your resume and applying for roles that match your new skills and expertise.

By focusing on these steps after qualification, you can ensure ongoing success and take advantage of new career opportunities. Remember, growth in this field is a continuous process, and staying proactive is key to long-term success.